Kitchen work shoe sole and shoe with shoe sole

A kitchen and shoe sole technology, applied to shoe soles, footwear, clothing, etc., can solve the problems of increasing the friction between the sole and the ground, reducing friction, slipping, etc., to improve friction, maintain dryness, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

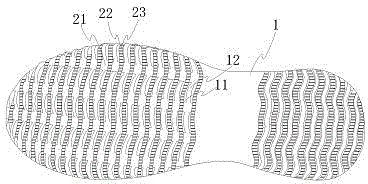

[0014] refer to figure 1 , the embodiment of the present invention discloses that a kitchen worker's shoe sole includes an outsole 1, and the outsole 1 is evenly arranged with a plurality of wavy anti-slip strips 2 along its length direction, and the wavy anti-slip strips The strips 2 transversely run through the side edge of the outsole 1, and guide slots 21 are formed between adjacent wavy anti-slip strips 2, and the wavy anti-slip strips 2 are evenly distributed on the surface in contact with the ground. Two racks 22, and drainage gaps 23 are formed between adjacent racks 22, and the drainage gaps 23 communicate with the diversion slots 21; , the outsole 1 is provided with a slot 11 at the position where the trough section of the wavy anti-slip strip 2 is located, and the trough section of the wavy anti-slip strip 2 is laid on the bottom of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com