Mine truck lifting prohibition walking hydraulic system

A technology for hydraulic systems and mine vehicles, which is applied in hoisting devices, fluid pressure actuating devices, servo motors, etc., to ensure walking safety and improve safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

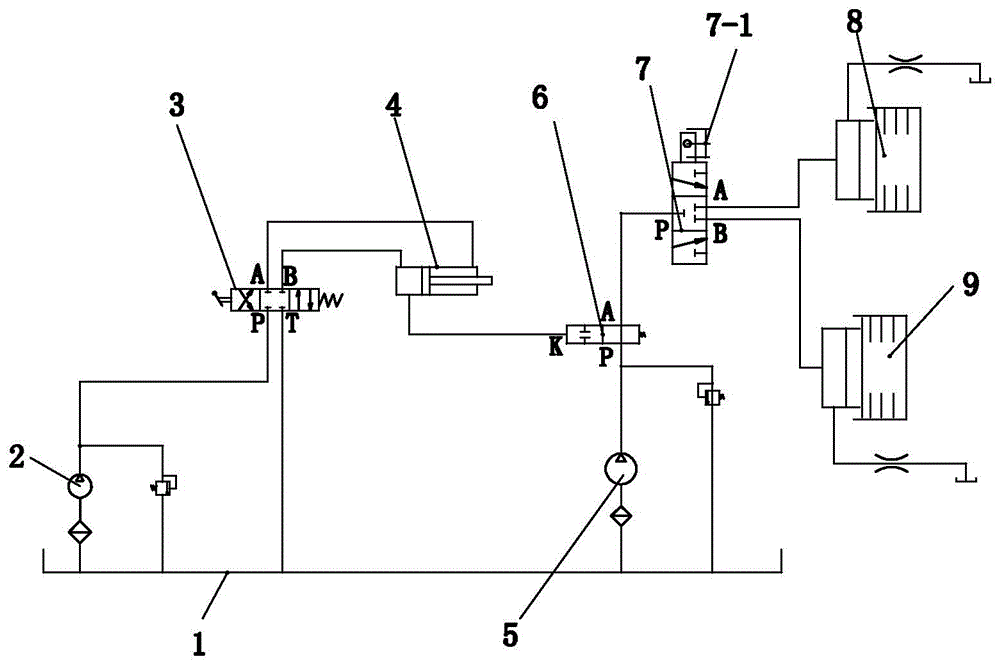

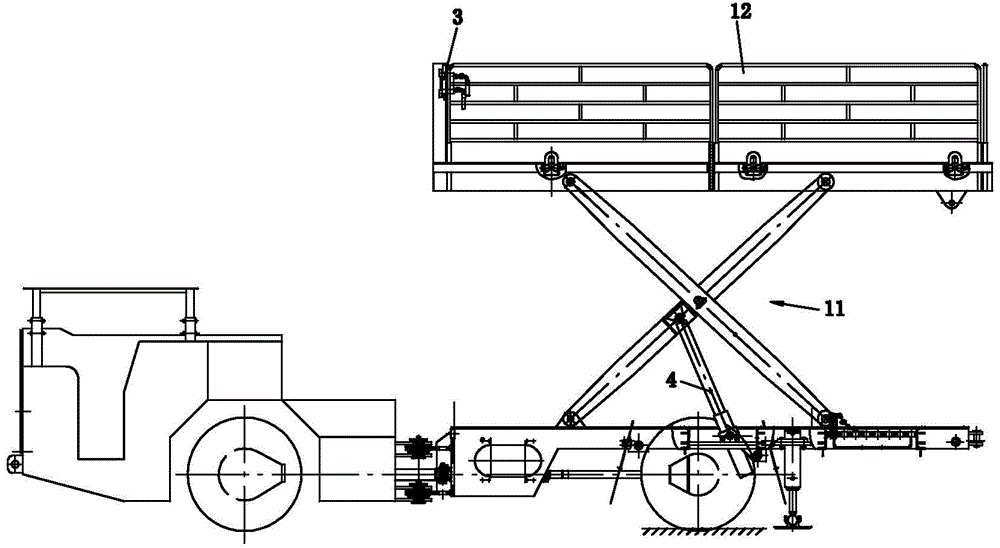

[0009] See figure 1 and figure 2 , The mining vehicle has a front frame and a rear frame, the rear frame is provided with a lifting seat 11, and the lifting seat 11 is connected with a compartment 12.

[0010] The hydraulic system for lifting and prohibiting walking of the mining vehicle includes a fuel tank 1, a first hydraulic pump 2, a manual reversing valve 3, a lifting cylinder 4, a second hydraulic pump 5, a power cut-off valve 6, a gear selection operation valve 7, and a forward gear Clutch 8, reverse gear clutch 9. The select operation valve 7 includes a joystick 7-1. Lifting oil cylinder 4 controls elevating seat 11 lifting, and elevating seat 11 drives compartment 12 lifting, and the action of lifting oil cylinder 4 is controlled by manual reversing valve 3, and manual reversing valve 3 is installed on the carriage 12.

[0011] The oil inlets of the first hydraulic pump 2 and the second hydraulic pump 5 are connected with the oil tank 1, the oil outlet of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com