Prediction method of thermal fatigue life of BGA (Ball Grid Array) welding spot considering influence of sequential temperature cycling load loading

A load sequence and life prediction technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of no mature methods and limited research work, and achieve the effect of engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

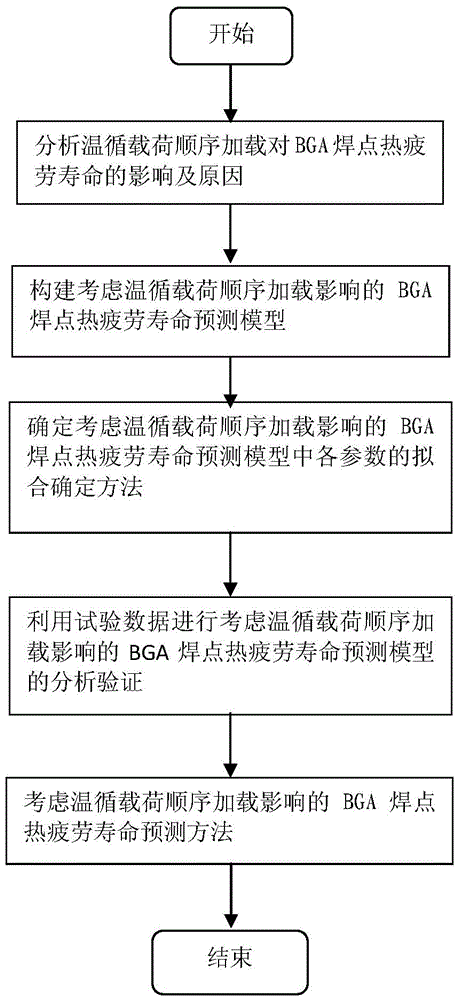

[0036] The BGA solder joint thermal fatigue life prediction method considering the impact of temperature cycle load sequence loading according to the present invention, see figure 1 As shown, the specific implementation steps of the method are as follows:

[0037] Step 1. According to the test data, the influence and reason of sequential loading of temperature cycle load on the thermal fatigue life of BGA solder joints are analyzed.

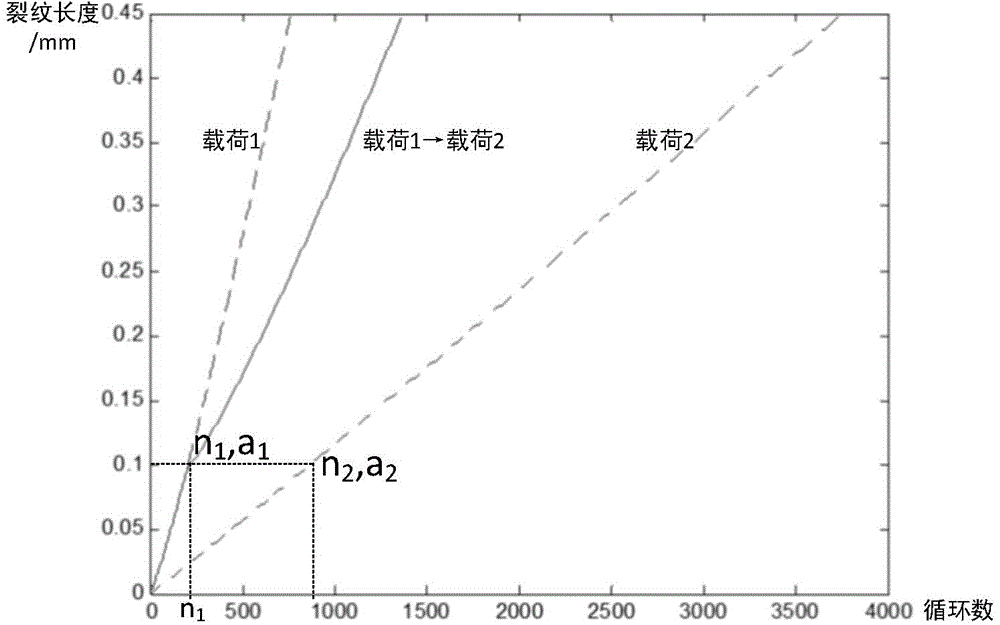

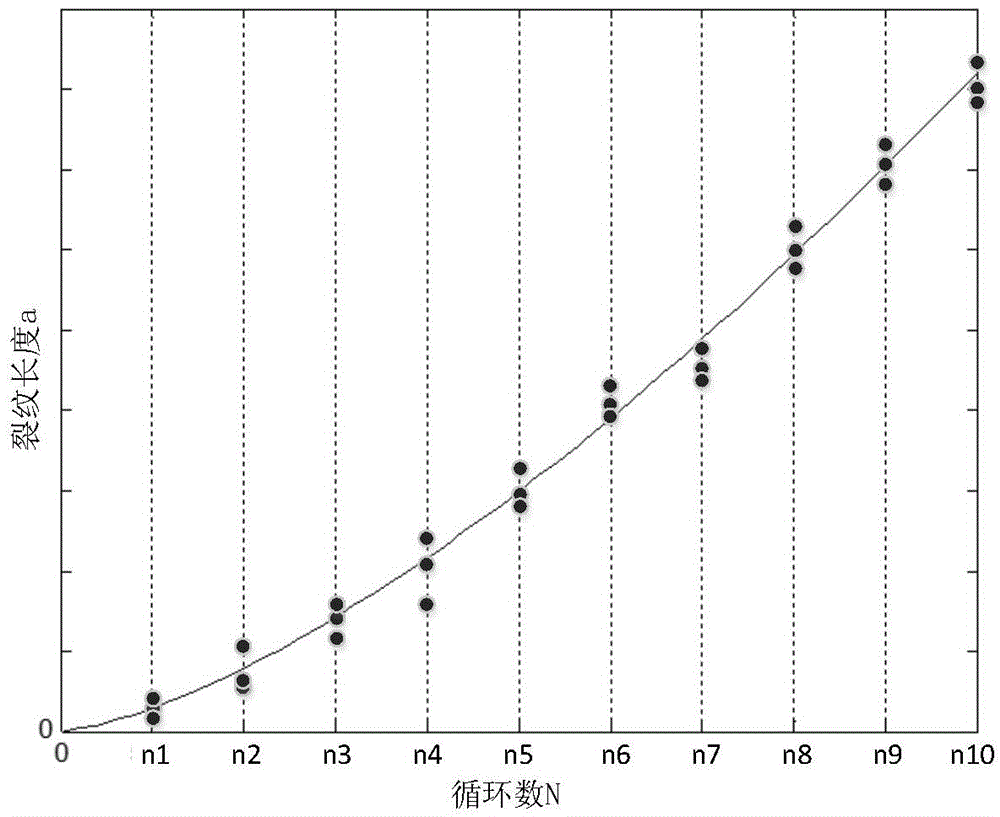

[0038] The influence of sequential loading of temperature cycle load on the thermal fatigue life of BGA solder joints is as follows: when the temperature cycle load is loaded sequentially from high to low, the fatigue life measured in the thermal fatigue test of BGA solder joints is shorter than the fatigue life predicted by Miner theory, while When the temperature cycle load is loaded sequentially from low to high, the fatigue life measured by the test is longer than that predicted by Miner's theory.

[0039] The reasons for the above effects a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com