Automatic vending machine

A vending machine and shelf technology, which is applied to instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. and other problems, to achieve the effect of cost reduction, reduction in the number of motors, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are described in detail below:

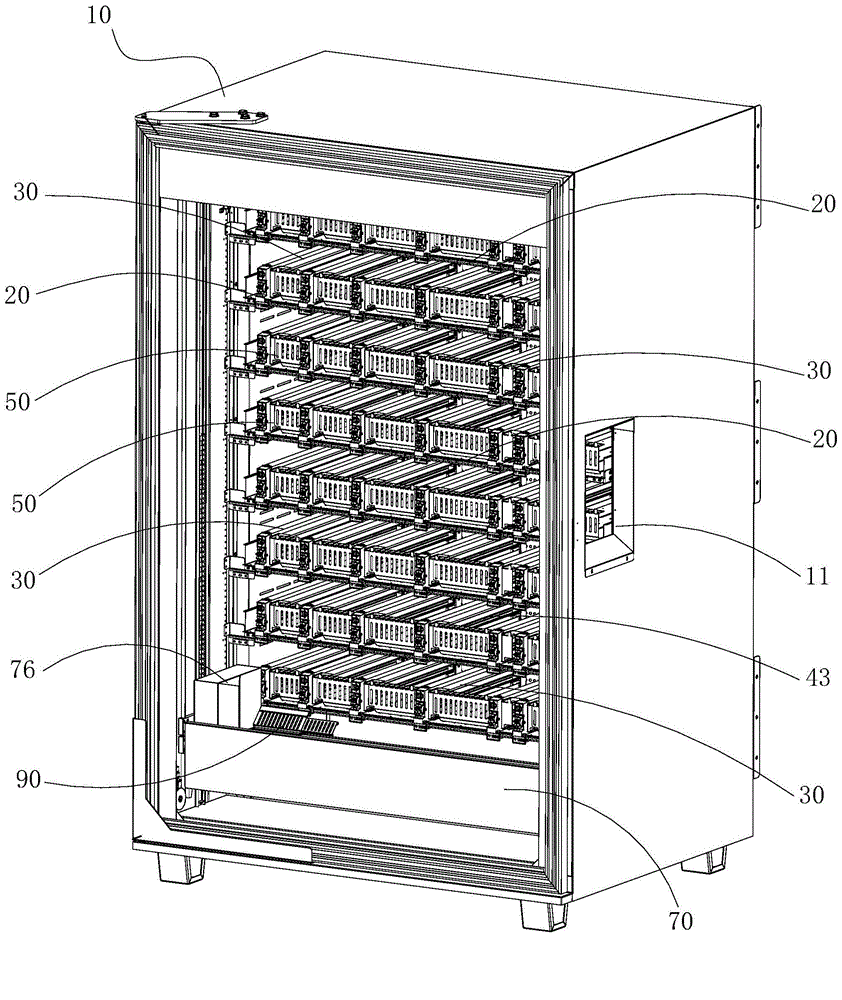

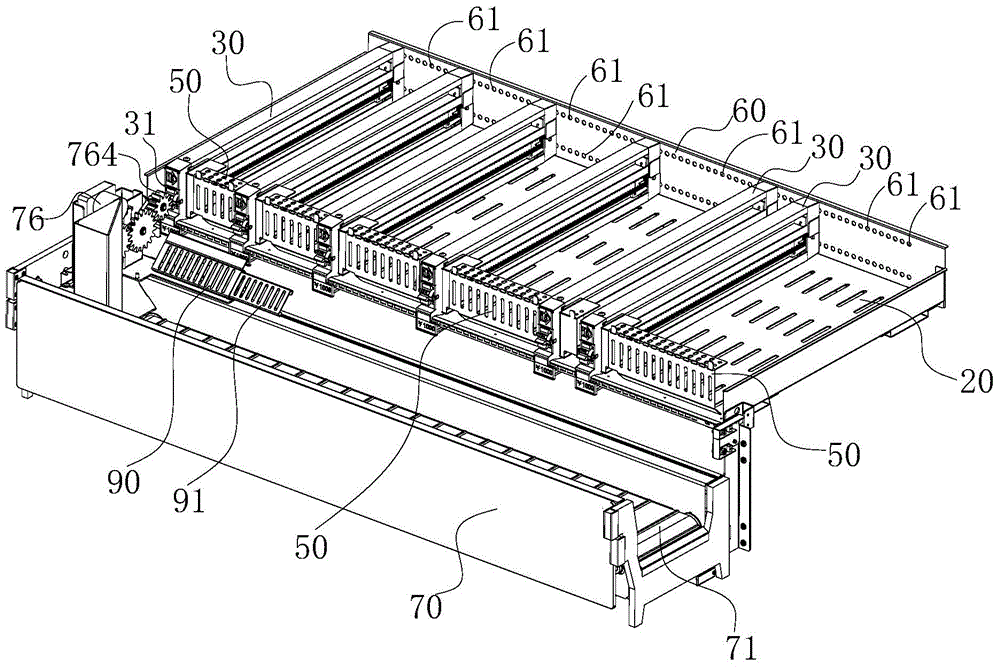

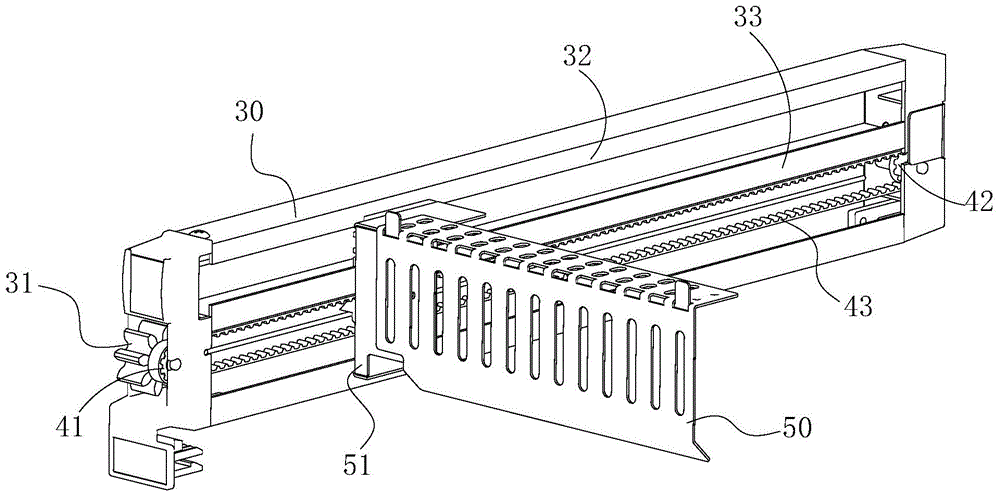

[0035] like figure 1As shown, the automatic vending machine of the present invention includes a box body 10, a shelf 20, a partition 30, a first synchronous wheel 41 and a second synchronous wheel 42, a push plate 50, a first gear 31, a goods receiving groove 70 and a lift Mechanism 80 , moving assembly 75 and drive structure 76 . The shelves 20 have one row or more than one row, and the shelves 20 are arranged in the box body 10 . see Figure 2-4 , There is more than one divider 30 and it is arranged in the shelf 20 to divide the shelf 20 into more than one cargo lane. The first synchronous wheel 41 and the second synchronous wheel 42 are disposed on the separator 30 , and a first synchronous belt 43 is connected to the first synchronous wheel 41 and the second synchronous wheel 42 . The push plate 50 is provided with more than one, and the push plate 50 corresponds to the cargo lane one by one. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com