Transparent note sheet and manufacturing method thereof

A technology of sheets and sticky notes, which is applied to chemical instruments and methods, packaging and identification devices of single-fed paper not glued into pads, etc., can solve the problems such as difficult adjustment of fine protrusions, and achieve excellent writability , low haze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0122] The present invention will be further explained with reference to the following illustrative examples and comparative examples of the present invention.

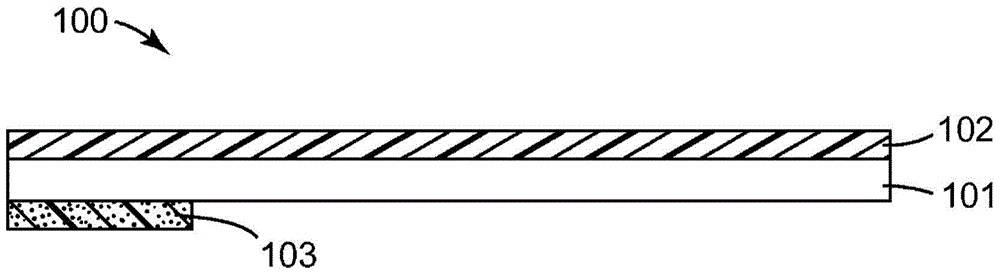

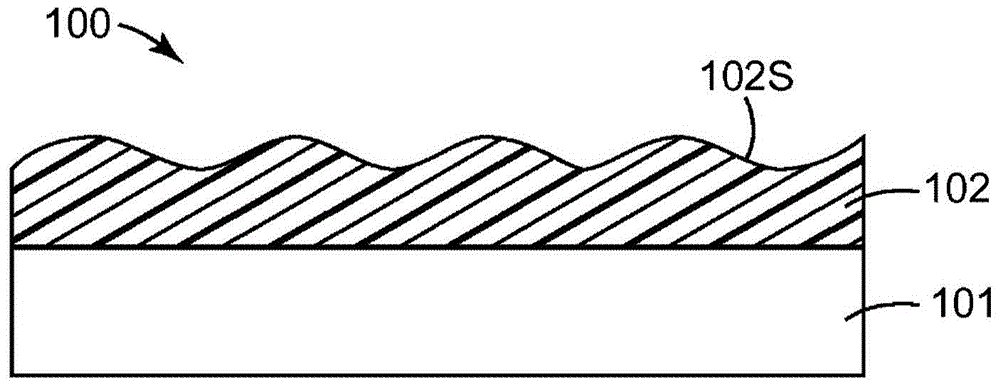

[0123] Examples 1 to 24

[0124] In Examples 1 to 24, primer-treated polyethylene terephthalate (PET) film (MELINEX TM 618, available from U.S. DuPont Teijin Film Co., Ltd.) as a substrate to make the note of the present invention, the film has a width of about 9 inches (22.86 cm) and a thickness of about 5 thousandths of an inch (0.127 mm). Used as a resin substrate.

[0125]As shown in Table 1, the coating layer precursor was made of a commercially available UV-curable acrylic resin hardcoat material (906 Hardcoat, manufactured by 3M), which can be Used alone or mixed in a blend of propoxylated (2) neopentyl glycol diacrylate (SR9003, manufactured by Sartomer, LLC).

[0126] Use with Figure 5 In the continuous manufacturing system configured in the manufacturing system system shown in , the resin coating lay...

example 4

[0143] A photomicrograph of the fine relief structure of the front surface of the Example 4 note sheet is in Figure 11 shown in .

[0144] For each of Examples 1 to 24, manufacturing conditions (composition ratio of coating material, film thickness of coating layer precursor), unevenness formation evaluation (surface roughness and distance between adjacent peaks), optical characteristics (transmittance and haze), and writability are shown in Table 1.

example 1

[0145] The optical properties of the note sheet of Example 1 and a commercially available film-type marker used in Comparative Example are shown in Table 2.

[0146] Haze values and values (R a / NNp) in Figure 12 shown in . Also, writability and value (R a / NNp) in Figure 13 shown in .

[0147]

[0148] [Table 2]

[0149] sample Haze (%) Transmittance(%) Example 1 29.9 94.0 Comparative example 1 85.16 79.18 Comparative example 2 77.67 97.01 Comparative example 3 66.80 96.40

[0150] Examples 25 to 41

[0151] In Example 25, the primer-treated PET film (MELINEX TM 618, commercially available from DuPont Teijin Films, USA) was used as the substrate, the film having a width of about 9 inches (22.86 cm) and a thickness of about two thousandths of an inch (0.0508 mm). In addition, a commercially available ultraviolet-curable acrylic resin hard coat material (906HC, manufactured by 3M) was used alone as the coating m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| hazing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com