Hollow filter stick molding equipment

A technology of forming equipment and hollow filter rods, which is applied in e-liquid filter, application, food science and other directions, can solve problems such as single function, and achieve the effect of high forming efficiency, low rejection rate and exquisite structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

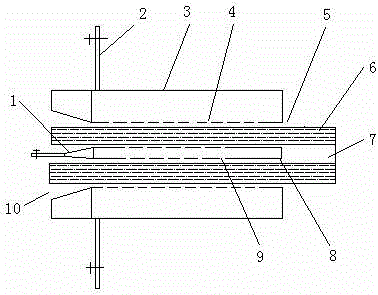

[0021] Such as figure 1 The mold of the forming equipment of the hollow filter rod has a shell mold 3 and a core mold 8 located at the center of the shell mold 3, and also has a steam source connected to the shell mold 3 and the inner cavity of the core mold 8 respectively. Pipeline 2; the main part of the inner wall of the shell mold 3 is a cylindrical shape, and the inner wall has a length of 40-50 cm and is distributed with numerous shell steam holes 4; the main part of the outer wall of the mandrel 8 is a cylindrical shape. The outer wall has a section with a length of 30-35cm and numerous core steam holes 9 distributed therein.

[0022] The number of shell steam holes 4 and core steam holes 9 is moderate, so that the injection amount of steam can meet the heating and bonding requirements of triacetin and cellulose acetate tow in the filter element, and is not saturated. The diameter of each shell steam hole 4 is 0.3-0.6mm, and the size of the core steam hole 9 is not lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com