Injection moulding machine

An injection molding machine and injection system technology, applied in the field of injection molding machines, can solve problems such as leakage of glue, easy wear of nozzles, and inability to precisely control the contact force of nozzles, avoiding excessive size, avoiding deflection torque, and saving cost and space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

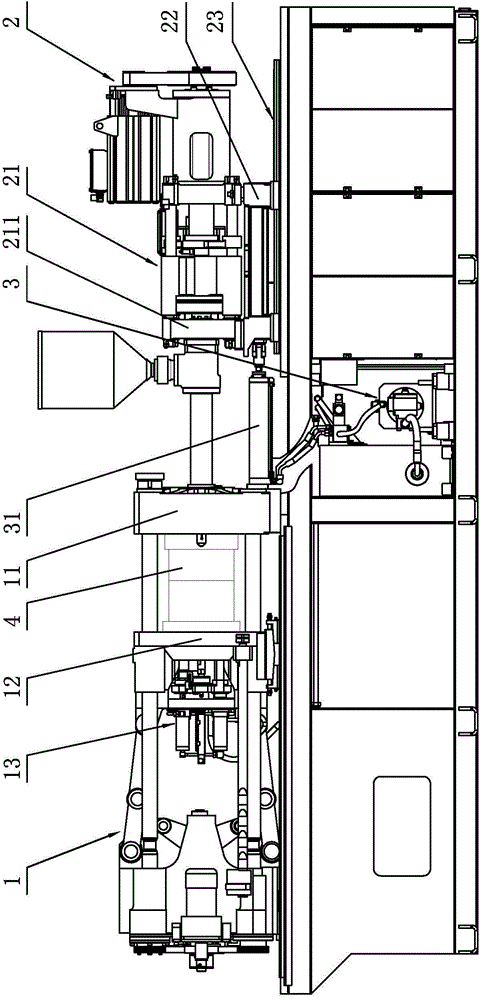

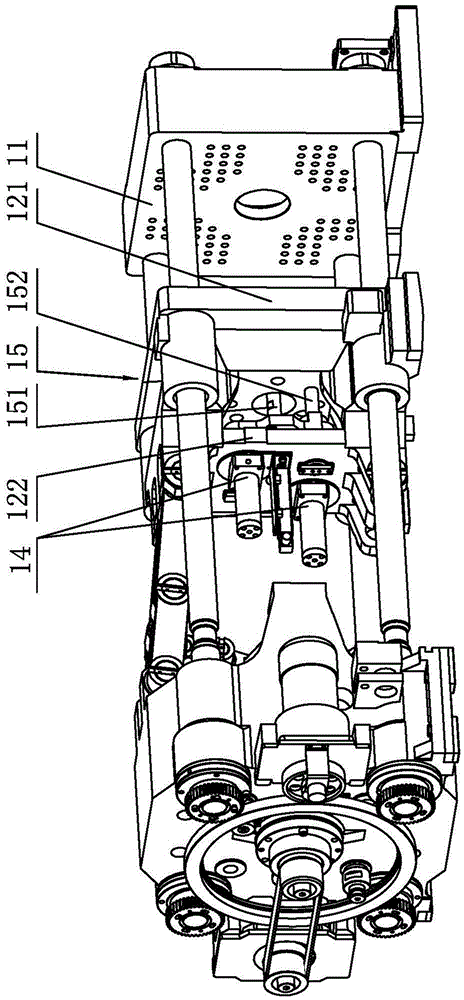

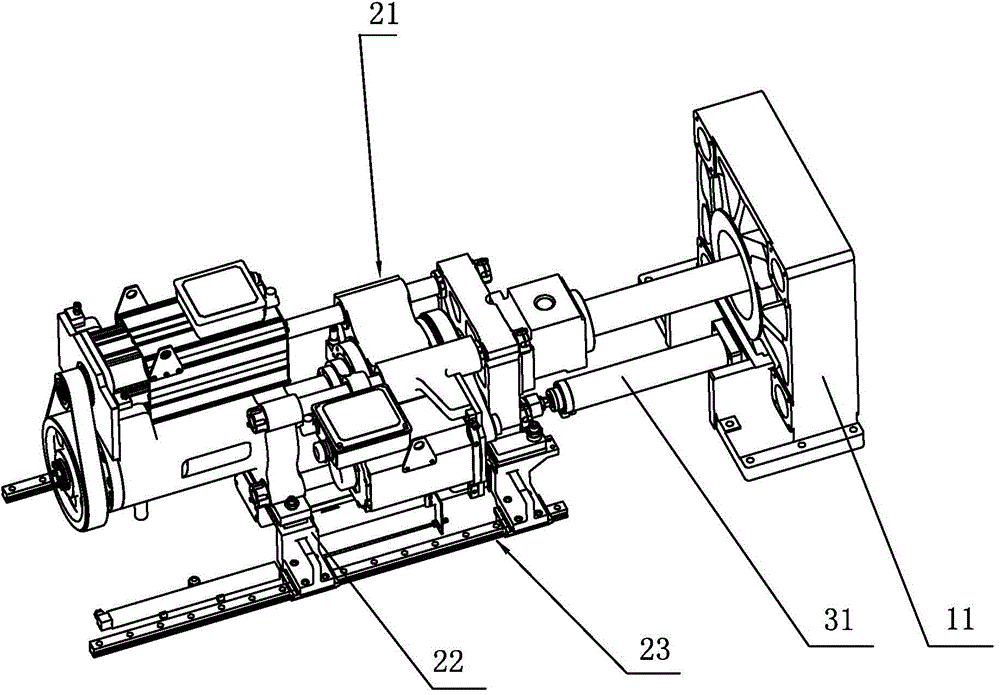

[0033] Embodiment one: if Figure 1-9 As shown, an injection molding machine includes a clamping system 1 and an injection molding system 2, the clamping system 1 includes a fixed template 11, and the injection molding system 2 is provided with a servo hydraulic system 3 for driving the injection molding system 2 to move relative to the fixed template 11 , the servo hydraulic system 3 includes a full shift oil cylinder 31 and a full shift oil cylinder hydraulic control mechanism 32, the full move oil cylinder 31 and the full move oil cylinder hydraulic control mechanism 32 are connected through oil pipes, and the cylinder body of the full move oil cylinder 31 is arranged on the fixed template 11, The injection molding system 2 includes an injection molding device 21, a moving support 22 and a guide rail assembly 23. The injection molding device 21 is fixedly installed on the moving support 22, and the moving support 22 is fixedly installed on the guide rail assembly 23. The movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com