Jetting system on tailpipe nozzle of jet airplane

A jet aircraft and tail nozzle technology, applied in the field of aircraft, can solve problems such as inability to retreat, inability to lift vertically, poor performance at low altitude and low speed, etc., and achieve the effect of increasing stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

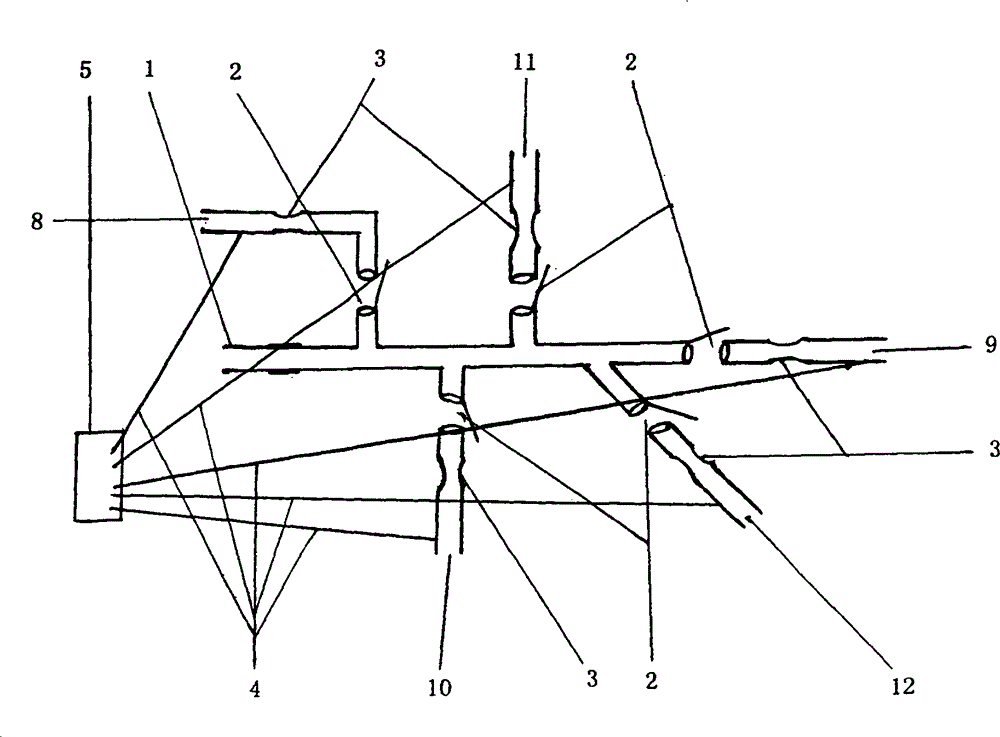

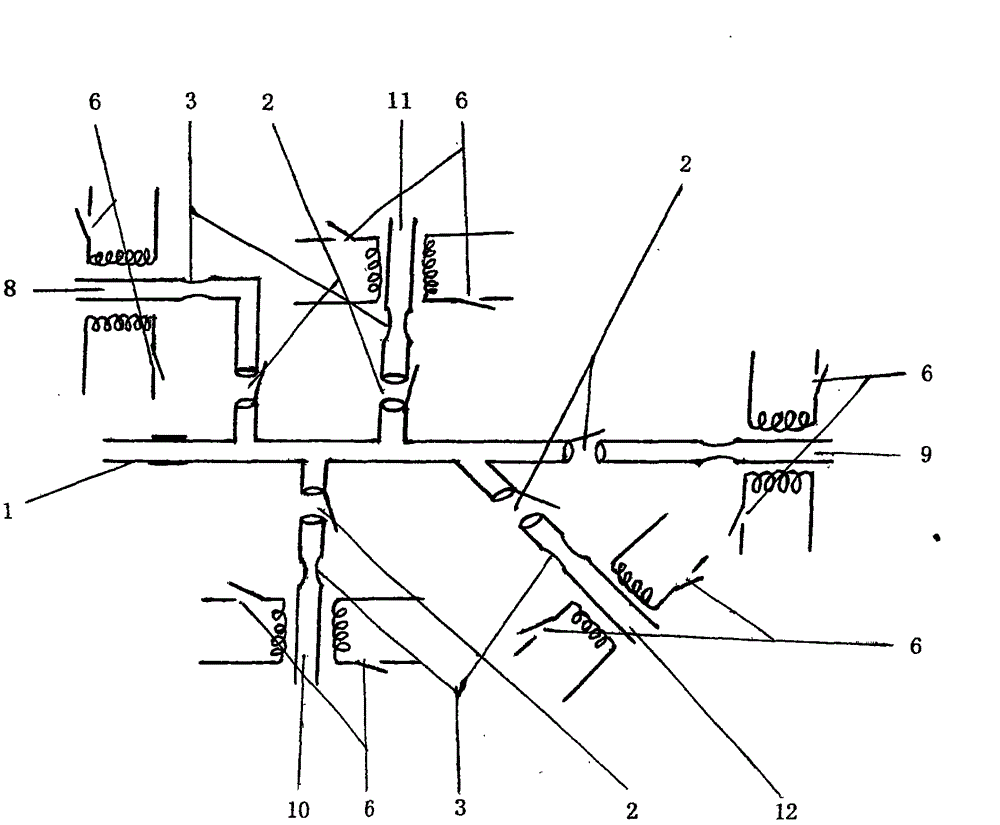

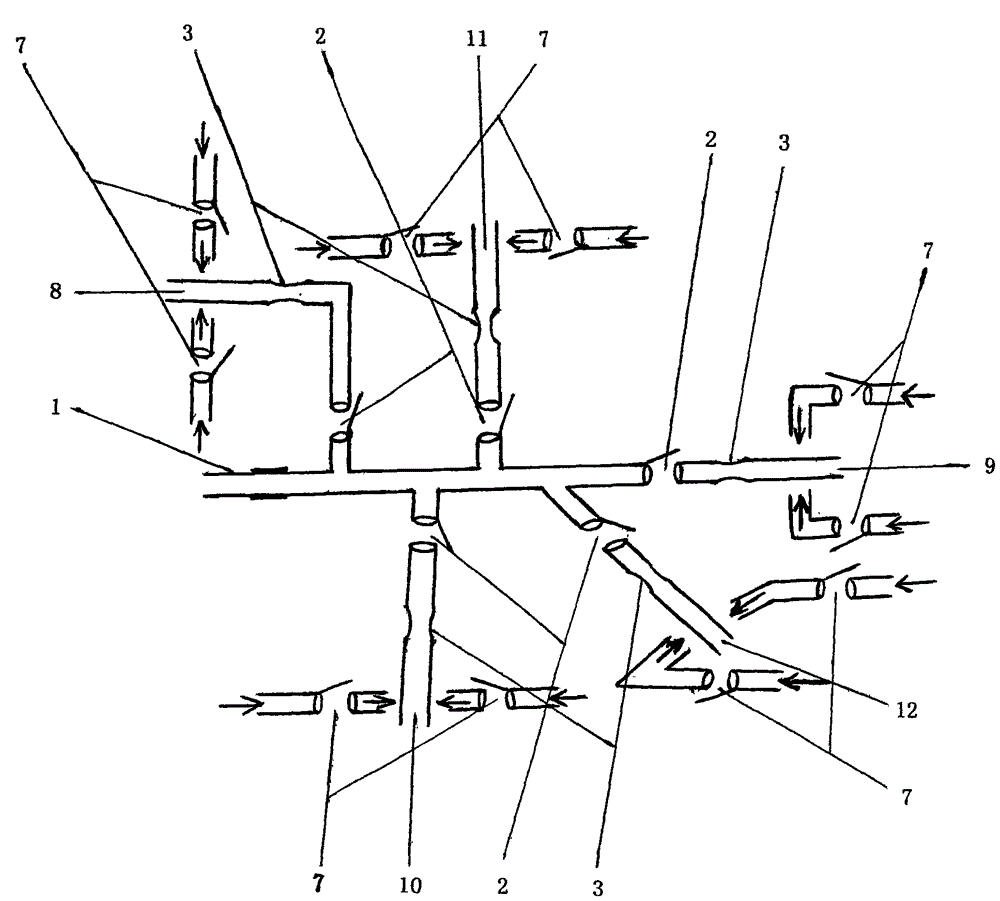

[0011] figure 1 , figure 2 , image 3 It is a forward jet system installed on the tail nozzle of a jet aircraft, and consists of a gas switch 2, a high-temperature-resistant soft air pipe 3, a hard air pipe, and a direction controller. The front end of the main air pipe of the system is connected with the tail nozzle of the jet aircraft, and then the front jet pipe 8 and its direction controller are installed in sequence, the left and right jet pipes 10, 11 and their direction controllers, and the down jet pipe 12 and its direction control device, followed by the jet pipeline 9 and its direction controller. figure 1 , figure 2 , image 3 The three jet systems are identical except for the direction controller. The gas switch 2 controls the size of the airflow, and the direction controller controls the direction of the airflow.

[0012] Figure 4 , Figure 5 , Image 6 It is the back-jet system installed on the tail nozzle of jet aircraft, and figure 1 , figure 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com