Guiding device for aluminum plate

A guiding device and aluminum plate technology, applied in transportation and packaging, object supply, flipping objects, etc., can solve the problems of reducing product quality, easily damaging aluminum plates, reducing work efficiency, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

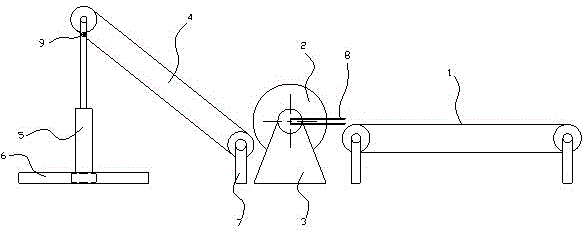

[0012] The present invention as Figure 1-2 As shown, it includes a transmission belt one 1, a rotating roller 2, a transmission belt two 4, a pair of lifting mechanisms 5 and a slide rail 6, and the transmission belt one 1, the rotation roller 2 and the transmission belt two 4 are arranged in sequence, and the transmission belt - 1 is set horizontally, the rotating roller 2 is movably arranged on the support 3, and the two sides of the support 3 are respectively provided with guide grooves 8 for placing aluminum plates;

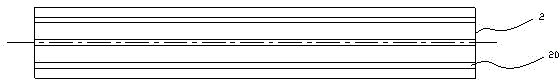

[0013] The surface of the rotating roller 2 is uniformly provided with several axial sockets 20, the transmission belt 2 4 is arranged obliquely, and one end of the transmission belt 2 4 adjacent to the rotating roller 2 is fixed on the support 7, and the other end is The pair of lifting mechanisms 5 are connected to the slide rails 6 , and the pair of lifting mechanisms 5 are respectively arranged on both sides of the conveyor belt 2 . The top of the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com