Efficient intercalation stripping method of micrometer graphite flakes and low-order graphite intercalation compounds and micrometer thin-wall porous expanded graphite

A technology of graphite flakes and graphite intercalation, which is applied in the fields of high-efficiency intercalation and exfoliation of micron graphite flakes, low-order graphite intercalation compounds and micron thin-walled porous expanded graphite. Inhomogeneity, low expansion volume and other problems, to achieve the effect of shortening the process time, avoiding secondary pollution, and easy equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

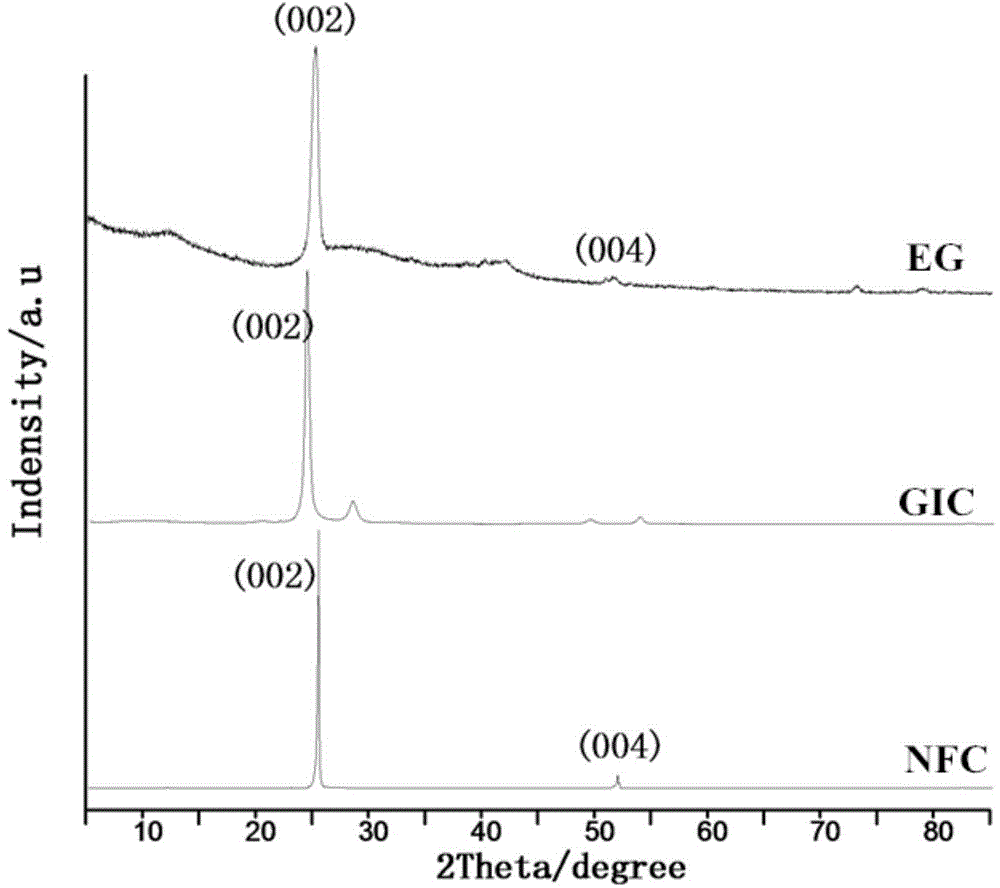

[0028] Example 1 : The efficient intercalation stripping method of the micron graphite flake provided by the invention adopts a one-step composite oxidation intercalation system, and basic materials are natural flake graphite (NFG), HClO 4 、HNO 3 、CH 3 COOH and KMnO 4 , and the material mass (g) volume (ml) ratio is:

[0029] NFG:HNO 3 :KMnO 4 :HClO 4 :CH 3 COOH=2g:1.6mL:0.68g:6.3mL:1.5mL.

[0030] where KMnO 4 as oxidizing agent, HClO 4 and HNO 3 is a composite oxide intercalator, CH 3 COOH is a synergistic auxiliary intercalation agent, the reaction time is 15min, ultrasonic waves and mechanical stirring are applied alternately at the same time, the reaction temperature is 35°C, and the puffing treatment temperature is 900°C.

[0031] Concrete preparation steps:

[0032] Build the reaction apparatus. Adjust and set the heating temperature of the water bath to 35°C, build a fixed three-necked flask on an iron stand, put a stirring rod in the three-necked flask,...

Embodiment 2

[0038] Example 2 : High-efficiency intercalation stripping method is adopted, and the basic materials are natural flake graphite (NFG), HClO 4 、HNO 3 、CH 3 COOH and KMnO 4 , and the material mass (g) volume (ml) ratio is:

[0039] NFG:HNO 3 :KMnO 4 :HClO 4 :CH 3 COOH=2g:1.6mL:0.68g:3.6mL:1mL, the specific preparation steps are as follows:

[0040] HNO 3 , KMnO 4 and HClO 4 Mix and prepare the main reaction solution, then add the main reaction solution to natural flake graphite, and add CH dropwise 3 COOH, the reaction time is 10min, and the reaction temperature is 45°C. During the reaction process, mechanical stirring and ultrasonic assisted stirring are continuously performed, wherein the mechanical stirring speed is 90r / min, the ultrasonic cavitation power is 150W, and the frequency is 30KHz, and the ultrasonic assisted application time is not more than 1 / 4 of the reaction time. After the reaction is finished, wash with water, decolorize, and suction filter, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap