Split combined intelligent oil-water separator of restaurant waste water and running method thereof

A technology for catering wastewater, oil-water separation, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve problems such as adhesion of large grease and inability to clean up, and achieve the effect of ensuring the quality of effluent and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

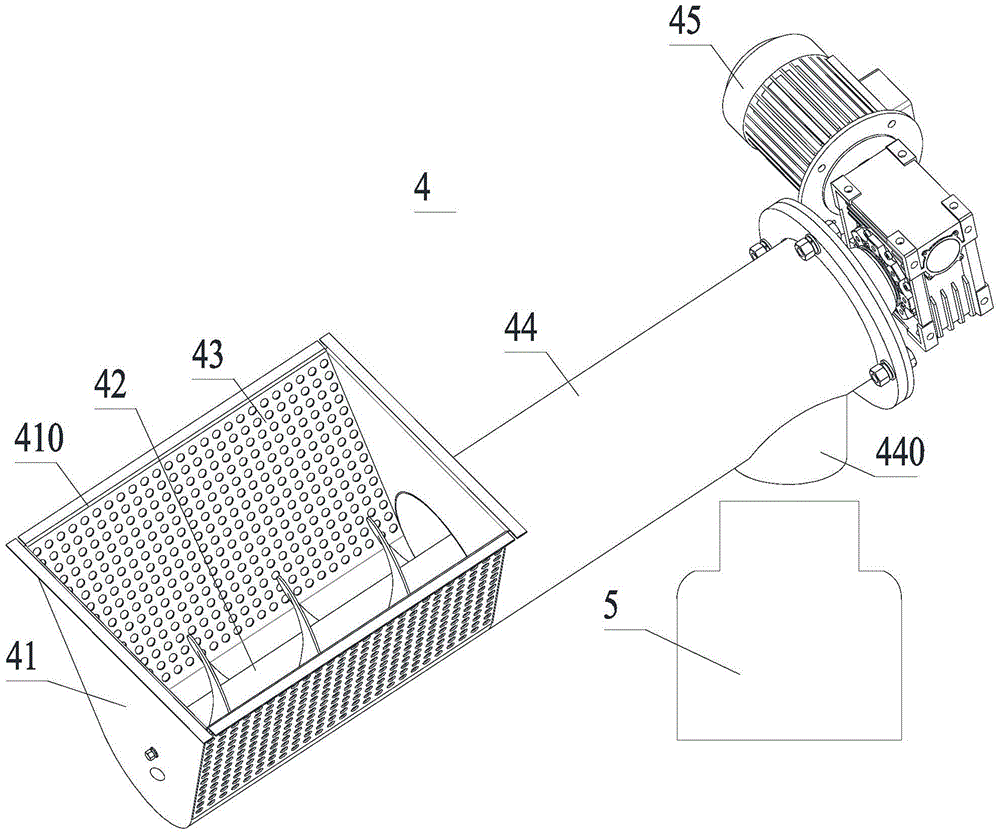

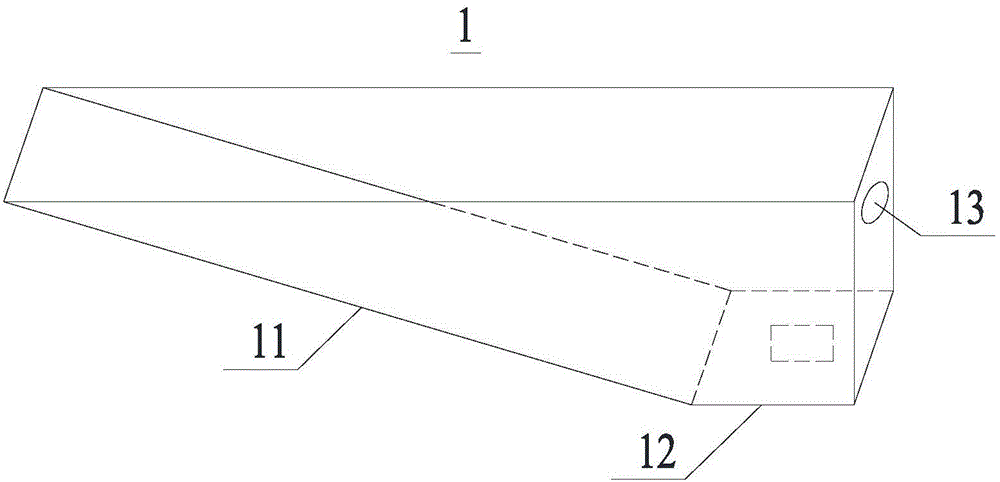

[0059] Please also refer to Figure 1 to Figure 4 , The split combined intelligent oil-water separation equipment for catering wastewater includes a sludge collection box 1, an oil collection box 2, an oil scraper 3, a debris cleaning machine 4, a kitchen trash can 5, an oil barrel 6, and a water outlet pipe 7.

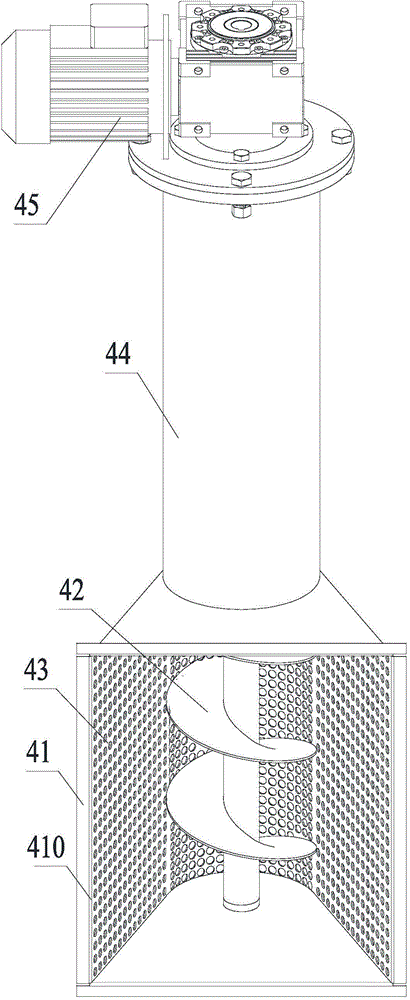

[0060] Please also refer to figure 1 and figure 2 , The debris cleaning machine 4 includes a debris separation box 41, an auger 42, a filter screen 43, a debris conveying path 44, and an auger motor 45. The debris separation box 41 is provided with an opening 410 , and the filter screen 43 is installed on the opening 410 . The filter screen 43 separates the swill solid-liquid into the foreign matter left on the filter screen 43 and the sewage of the flow filter screen 43, and the filter screen 43 is in the shape of "︶" so that the foreign matter separation box 41 has three surfaces for discharging sewage.

[0061] The debris conveying channel 44 communicates with ...

Embodiment 2

[0108] Embodiment 2 is roughly the same as Embodiment 1, and the difference is that the debris cleaning machine in Embodiment 2 includes a debris separation box and a filter screen, the bottom of the debris separation box is provided with an opening, and the filter screen is arranged on the opening. It is used to separate the solid-liquid of swill into the debris left on the filter screen and the sewage flowing through the filter screen. The sludge collection box 1 collects the sewage and performs subsequent treatment on the sewage with reference to the manner in Example 1.

[0109] Embodiment 2 solves two major technical problems of existing products: 1. The mud discharge function is not strong enough, which easily causes sludge deposits to be difficult to remove; 2. A large amount of grease adheres to the equipment box wall and cannot be cleaned; 3. The water after oil-water separation Still will bring out some oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com