Multi-pipe external-compression type mechanical circulation forced cross flow solid-liquid separation dynamic membrane system and device

A technology of solid-liquid separation and mechanical circulation, applied in filtration separation, separation methods, fixed filter element filters, etc., can solve the problems of hydraulic dead angle film thickness, unevenness, long film formation time, etc., and achieve short film formation time. , the effect of increasing the differential pressure and reducing the pre-coating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the present invention will be described in detail with reference to the drawings.

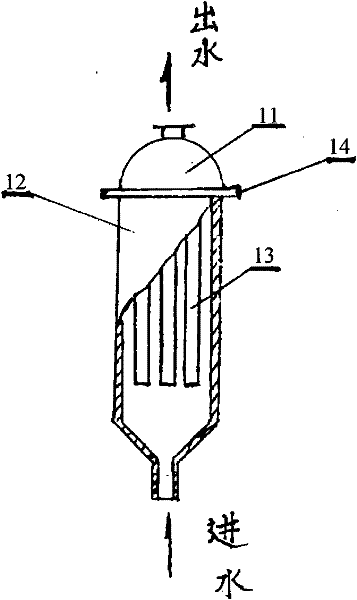

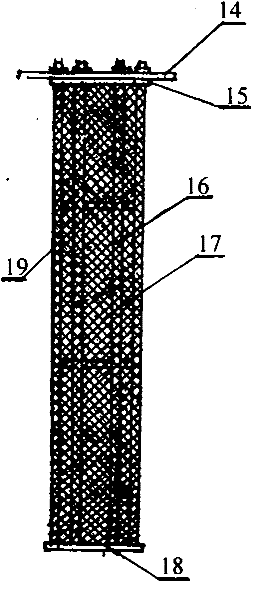

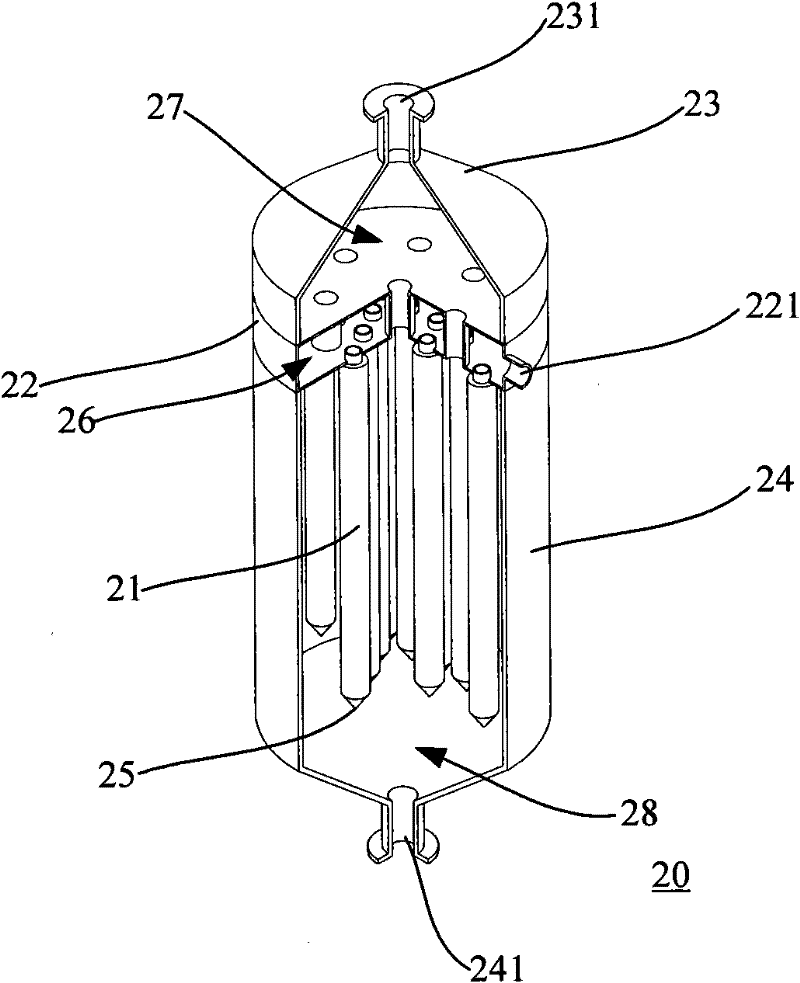

[0039] See Figure 3 to Figure 4 , Which are respectively a schematic structural diagram and a structural cross-sectional view of a dynamic membrane device for forced cross-flow solid-liquid separation with a multi-tube external pressure mechanical circulation of the present invention. The multi-tube external pressure type mechanical circulation forced cross-flow solid-liquid separation dynamic membrane device 20 includes: a plurality of tubular external pressure type supports 21, a water purification chamber 22, an upper cover 23, a shell 24 and a diversion cone 25. The inner cavity of the water cavity 22 forms a water purification chamber 26, and the water purification cavity 22 is provided with a water purification chamber for discharging filtered water, and used for the pre-coating and circulating return of the dynamic membrane and the reverse of the tubular external pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com