Green porous near-infrared reflective pigment and preparation method thereof

A reflective pigment, near-infrared technology, applied in fibrous fillers, coatings, etc., can solve the problems of not having both thermal barrier type heat insulation and heat reflection type heat insulation, no porous structure, etc., to achieve good near-infrared reflection. performance, improve thermal insulation performance, good acid and alkali resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

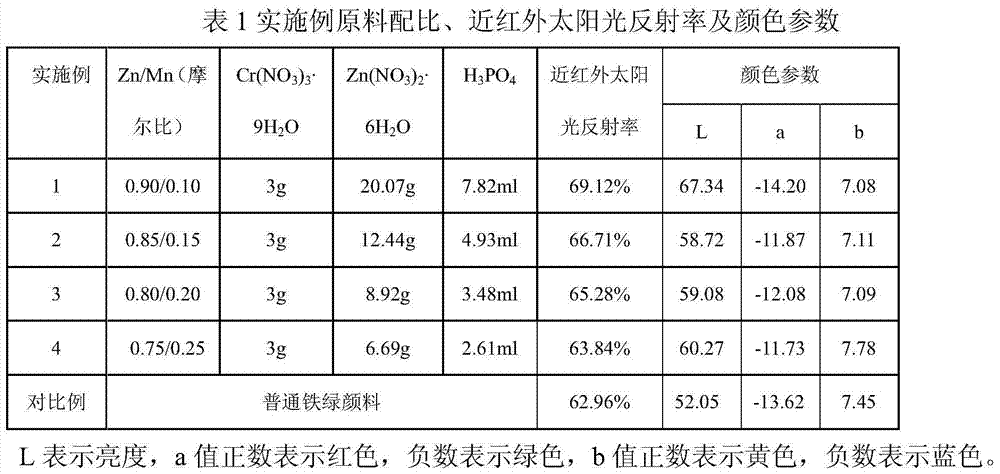

[0032] In order to facilitate those skilled in the art to further understand the present invention, the following examples are prepared according to the same preparation method.

[0033] The raw materials used in each embodiment are all commercially available.

[0034] Preparation:

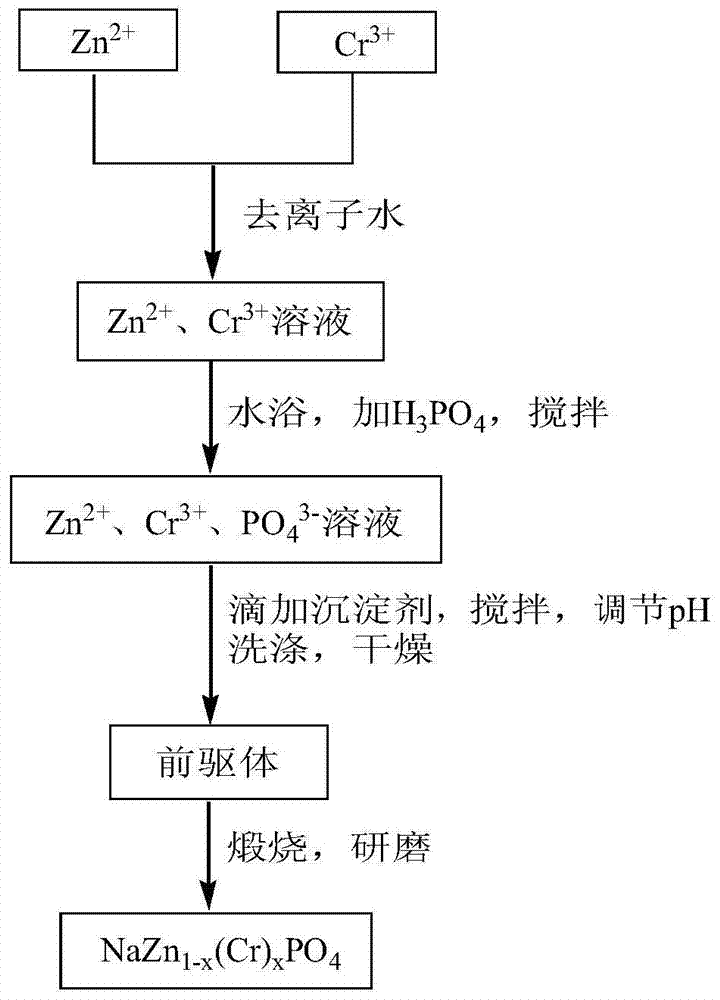

[0035] First, weigh Zn(NO 3 ) 2 ·6H 2 O and Cr(NO 3 ) 3 9H 2 Dissolve O in an appropriate amount of deionized water, stir at room temperature, transfer the solution to a three-necked flask, heat it in a water bath at 70°C, measure a certain amount of phosphoric acid with a concentration of 85%, slowly drop it into the three-necked flask, stir, and react for 1h , pour the mixed solution into a beaker, slowly add 2mol / L Na 2 CO 3 solution, stirring while adding dropwise, adjusting the pH value to 7, standing still, precipitation, suction filtration, washing twice with deionized water and once with absolute ethanol, and drying the filter cake in an oven at 70°C for 6h to obtain Precursor pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com