Fixed-type vibration absorption and noise reduction rubber support for rail transit bridge

A technology for vibration reduction and noise reduction, rail transportation, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of high cost, no large-scale horizontal displacement of the beam body, etc., achieve simple structure, ensure safety and stability, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

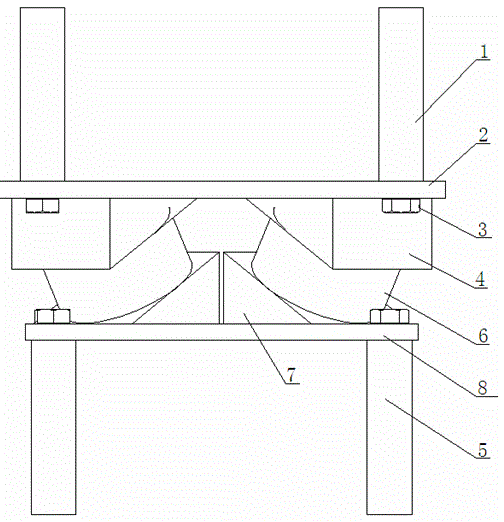

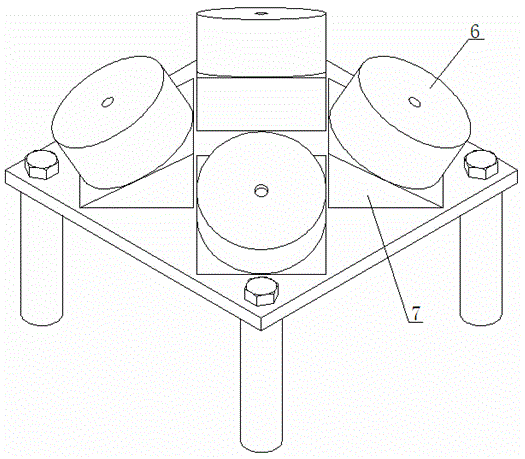

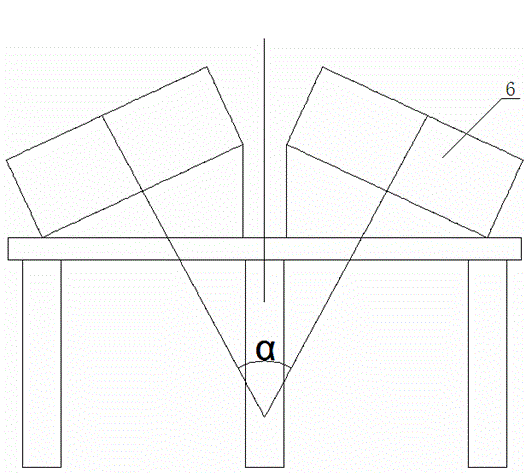

[0018] see figure 1 , figure 2 and Figure 4 , a fixed vibration-reducing and noise-reducing rubber bearing for a rail transit bridge, comprising an upper bearing plate 2 and a lower bearing plate 8; the upper bearing plate 2 is provided with four upper anchor rods 1, the Four lower anchor rods 5 are arranged under the lower bearing plate 8 . The lower support plate 8 is provided with four lower wedge-shaped fixed blocks 7, and the four lower wedge-shaped fixed blocks 7 are arranged oppositely; the bottom of the upper support plate 2 corresponds to the four lower wedge-shaped fixed blocks 7 Four upper wedge-shaped fixing blocks 4 are respectively arranged. Vulcanized rubber plates 6 are arranged between the corresponding lower wedge-shaped fixed blocks 7 and upper wedge-shaped fixed blocks 4 , and at this time, the central axes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com