Novel environment-friendly modified plastic circulation mold shell and construction method thereof

A plastic mold and plastic technology, which is applied in the fields of mold shell/template/work frame, building components, and on-site preparation of building components, can solve the problems of plastic mold shell damage, cumbersome construction process, long construction period, etc. The effect of construction cost, simplified fixing process, extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

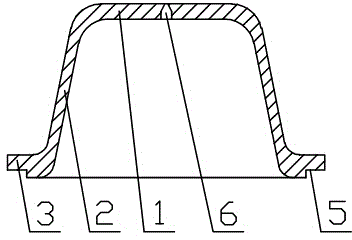

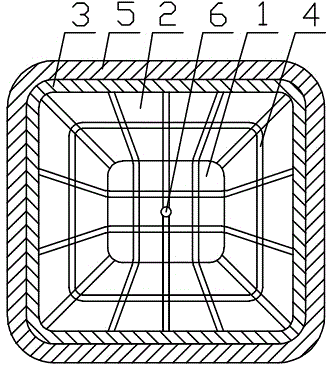

[0020] The invention provides a new type of environmentally friendly modified plastic turnover formwork, which includes a shell top 1, a shell body 2, a shell bottom 3, a reinforcing rib 4, a positioning edge 5, and a water outlet 6. The lower end of the shell top 1 is provided with an inclined The shell body 2, the lower end of the shell body 2 is provided with a shell bottom 3, the bottom of the shell bottom 3 is provided with a positioning edge 5, and the center position of the shell top 1 is provided with a moistening port 6, and the inner side of the shell top 1 and the shell body 2 is provided with There are stiffeners 4 arranged in a staggered manner.

Embodiment 2

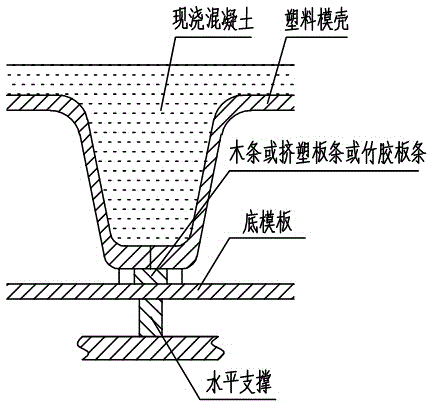

[0022] The construction method of a new type of environmentally friendly modified plastic turnover form provided by the present invention, the construction process is as follows:

[0023] ① Lay the bottom formwork: Lay the positioning formwork at the bottom of the rib beam in the way of full paving or strip paving;

[0024] ②Bounce positioning line;

[0025] ③Fixed formwork: Splicing the shell bottoms 3 of the plastic formwork together so that the positioning edges 5 on the shell bottoms 3 of two adjacent plastic forms are combined to form a positioning groove, and then the plastic formwork spliced together is installed At the upper end of the bottom mold, the positioning template is snapped into the positioning groove for positioning, which simplifies the fixing process of the plastic formwork, and makes the fixing of the plastic formwork more firm, which greatly avoids the occurrence of mold explosion and runaway when pouring concrete. The condition of the formwork can en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com