Middle pipe with liquid injection groove and groove structure and process for installing ball bearing

A technology of ball bearings and liquid injection tanks, which is applied in the direction of shafts and bearings, rigid supports of bearing components, bearing components, etc., which can solve problems such as complex assembly, difficulty in ensuring concentricity, and inability to meet the fixed requirements of ball bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

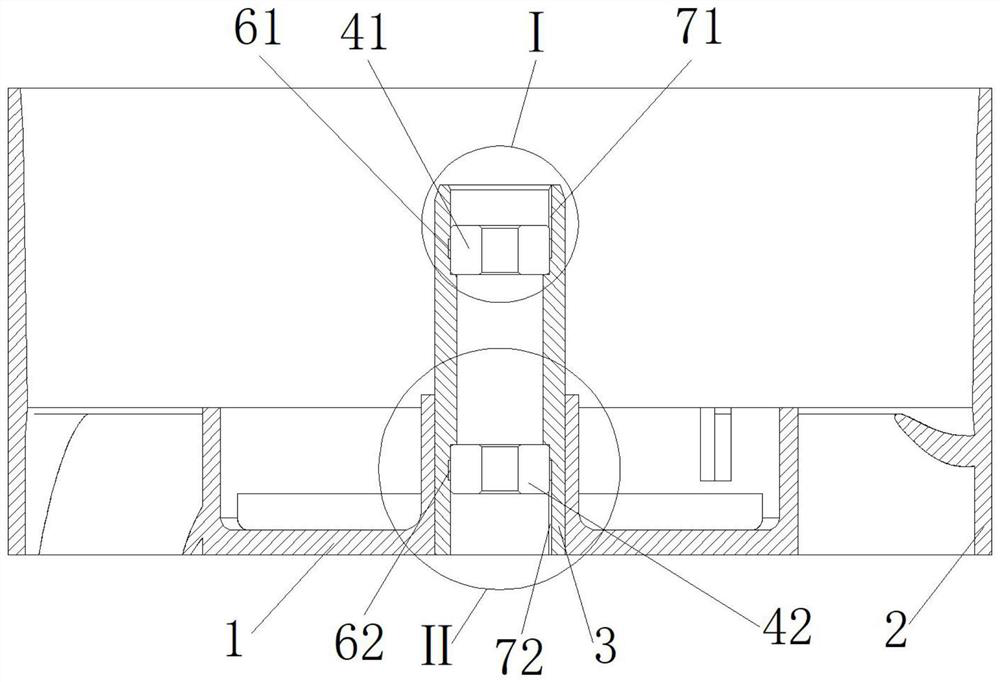

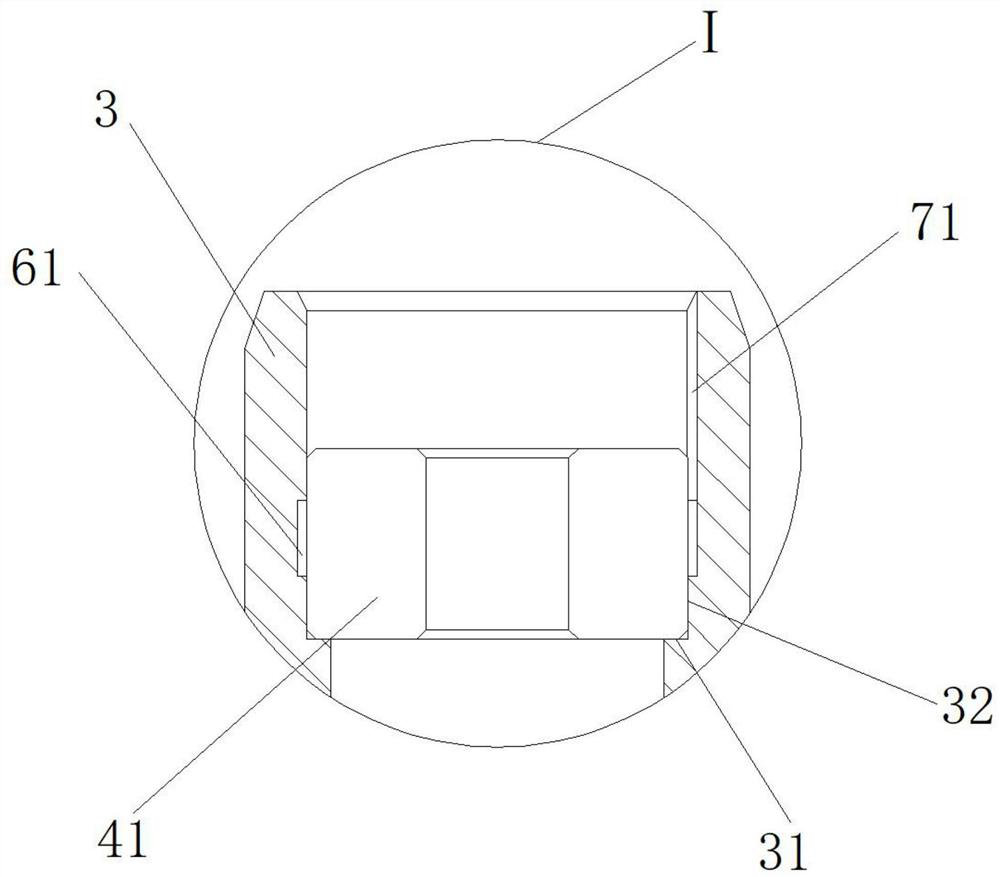

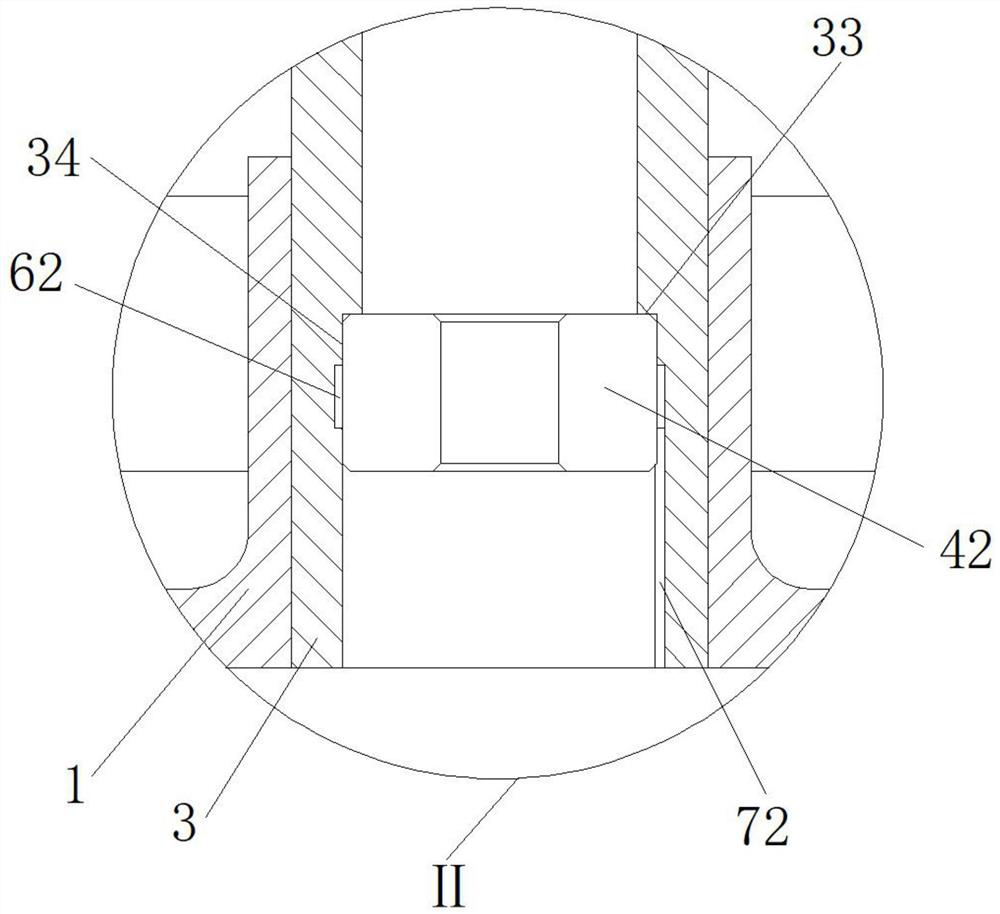

[0038] Please refer to figure 1 , Embodiment 1 of the present invention provides a middle pipe with a liquid injection groove and a groove structure, including a middle pipe 3, the middle pipe 3 is installed inside the stator hub 1, and the stator hub 1 is installed outside Inside the frame 2, one end of the middle tube 3 is bonded and fixed with a first ball bearing 41, and the other end is bonded and fixed with a second ball bearing 42. The first ball bearing 41 and the second ball bearing 42 are all fixedly installed on the middle pipe 3 by adhesive bonding.

[0039] One end of the middle tube 3 is provided with a first axial support ring end face 31 and a first radial support ring face 32, and the first axial support ring end face 31 is axially supported by the first ball bearing 41, so The first radial support annular surface 32 is radially supported by the first ball bearing 41, the first radial support annular surface 32 is provided with a first groove, and the first r...

Embodiment 2

[0048] Please refer to Figure 4 , Embodiment 2 of the present invention provides a middle pipe with a liquid injection groove and a groove structure. The difference from Embodiment 1 is that only the first annular groove 61 and the second annular groove 62 are changed to the first The helical groove 81 and the second helical groove 82 only change the shape of the groove containing the adhesive, so that the force uniformity of the first ball bearing 41 and the second ball bearing 42 is further improved.

[0049] Such as Figure 4 and 5 As shown, the first groove is a first helical groove 81, the first helical groove 81 spirally surrounds the first ball bearing 41, and the axial height of the first helical groove 81 is less than or equal to The height of the first ball bearing 41, the first radial support annular surface 32 is also provided with a first liquid injection groove 71, the first liquid injection groove 71 is a vertical groove, and the first liquid injection groove...

Embodiment 3

[0056] The third embodiment of the present invention provides that the present invention also provides a process for assembling the middle tube with a liquid injection tank and a groove structure described in the first and second embodiments to install the ball bearing, including the following steps :

[0057] Step S1: Place the bottom of the outer frame 2 downwards, and put the first ball bearing 41 into one end of the middle tube 3. Specifically, the first annular groove 61, the first ball bearing 41, and the first liquid injection tank Between 71 and the middle pipe 3, a first open communication chamber for accommodating the adhesive is formed;

[0058] Alternatively, a first open communicating spiral chamber for accommodating adhesive is formed among the first spiral groove 81 , the first ball bearing 41 , the first liquid injection groove 71 and the middle tube 3 .

[0059]Step S2: Extend the liquid injection nozzle into the first liquid injection groove 71, inject or fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com