Application of poly-1 and 5- dichloroanthraquinone in microorganism denitrification process and azo dyes micro-biological degradation process

A microbial degradation, dichloroanthraquinone technology, applied in physical/chemical process catalysts, chemical/physical processes, organic compounds/hydrides/coordination complex catalysts, etc., can solve azo dyes decolorization acceleration, hydraulic retention time It can achieve the effect of good biocompatibility, low production cost and not easy to be lost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

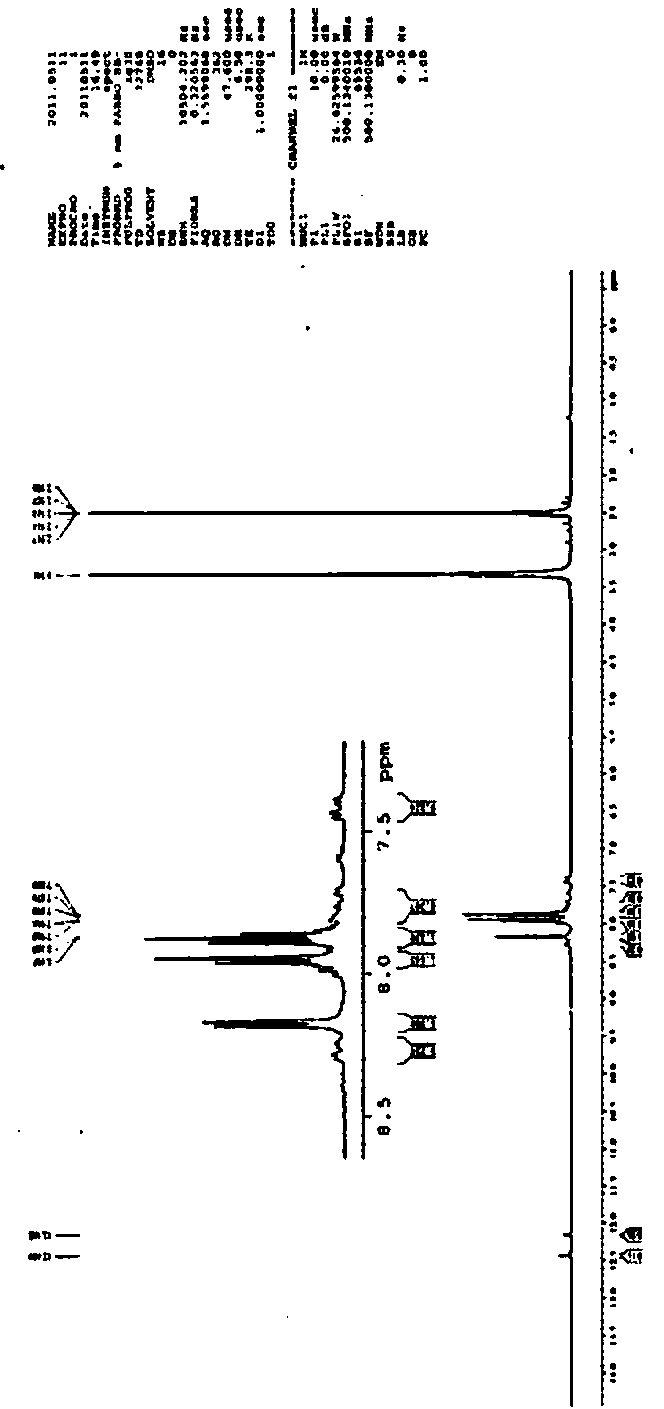

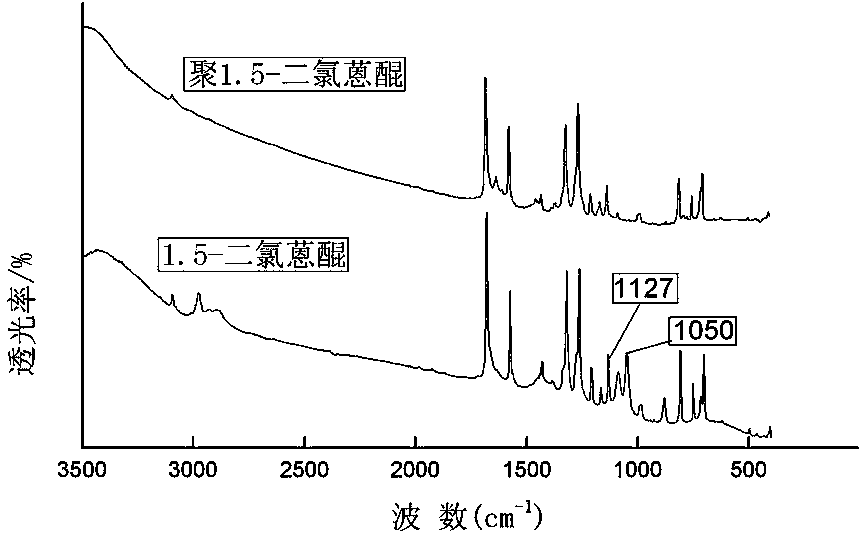

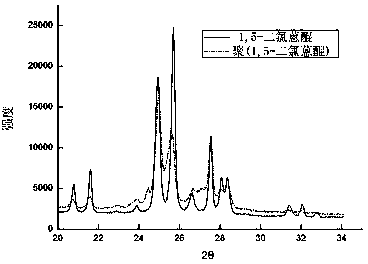

[0028] First synthesize poly-1,5-dichloroanthraquinone according to the following steps:

[0029] (1) Vacuumize the reactor with a circulating water-type multi-purpose vacuum pump, and then continue to feed nitrogen;

[0030] (2) Weigh 0.85mmol (0.2355g) of 1,5-dichloroanthraquinone and dissolve it in 14mL of DMF;

[0031] (3) Weigh 1.10mmol (0.303g) bis(1.5-cyclooctadiene) nickel, 1.10mmol (0.172g) bipyridine, measure 0.85mmol (104mmL) 1,5-cyclooctadiene dissolved in In another 14mL of DMF;

[0032] (4) Pour the DMF solution in step (2) into the four-necked bottle, turn on the heat-collecting constant temperature heating magnetic stirrer, and add the solution in step (3) into the four-necked bottle by dropwise adding Stir while stirring, start heating after the dropwise addition is completed, raise the temperature to 60°C under the protection of nitrogen, and keep the constant temperature. When reacting for 48 hours, pour the reaction solution into dilute hydrochloric acid ...

Embodiment 2

[0049] The catalytic activity of poly(1,5-dichloroanthraquinone) in the degradation of nitrite was studied.

[0050] The preparation method and fixation method of poly-1,5-dichloroanthraquinone are the same as in Example 1.

[0051] Adopt the same step and method as Example 1 to investigate the catalytic activity of immobilized poly 1,5-dichloroanthraquinone in 110mg / L nitrite wastewater containing denitrifying microorganisms in logarithmic growth phase in 250mL, the results are as follows Figure 6 shown.

[0052] It can be seen from the figure that when the system was reacted for 12 hours, the removal rate of nitrite in the system added with blank pellets and the system added with immobilized 1,5-dichloroanthraquinone was about 52%, while that of the system added with The nitrite removal rate in the system added with immobilized poly-1,5-dichloroanthraquinone can reach 98%, which shortens the time required for nitrite degradation. The results showed that: 1,5-dichloroanthr...

Embodiment 3

[0054] Taking acid red B (structural formula shown in formula 4) as an example, the application of poly-1,5-dichloroanthraquinone in the degradation process of azo dyes was studied.

[0055]

[0056] Formula (4)

[0057] The preparation method and fixation method of poly-1,5-dichloroanthraquinone are the same as in Example 1.

[0058] Using the same steps and methods as in Example 1 to investigate immobilized poly 1,5-dichloroanthraquinone in 250mL containing logarithmic growth phase of the azo dye degradation strain Staphylococcus Catalytic activity in the 150mg / L acid red B wastewater of sp.GYZ, the result is as follows Figure 7 shown.

[0059] It can be seen from the figure that when the system was reacted for 4.5 hours, the system with immobilized 1,5-dichloroanthraquinone and the system with immobilized poly-1,5-dichloroanthraquinone were better than those without quinone. The removal rate of mediator wastewater increased by 9.8% and 14.3%. The results showed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com