Method for improving petroleum recovery efficiency through air foam flooding assisted by microorganisms

A technology of air foam flooding and air foam, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of oil well shutdown and affect normal production, etc., and achieve the effect of improving properties and oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Composition of microbial-assisted air foam system: microbial nutrient, fermentation broth, and air foam system.

[0034] 1. The microbial nutrient composition is calculated by weight percentage (the same below): diammonium hydrogen phosphate (industrial product), 0.2%; sodium nitrate (industrial product) 0.1%; yeast powder (industrial product) 0.05%, corn steep liquor dry powder (industrial product) product) 0.2%; the rest is water.

[0035] 2. Microbial fermentation liquid: aerobic bacteria (mainly hydrocarbon oxidizing bacteria) fermentation liquid with a mass ratio of 5%, and the concentration of bacteria in the fermentation liquid is 3 × 10 8 pieces / ml.

[0036] 3. Air foam system composition: air; foaming agent (industrial product) 0.3%, and the rest is water.

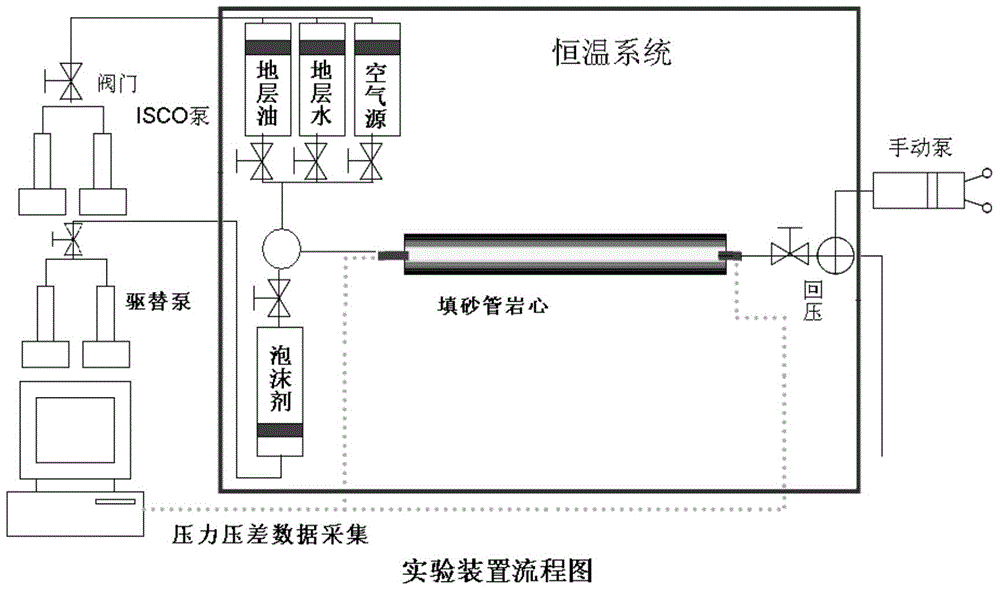

[0037] 2. Experimental method

[0038] The experimental water and microbial fermented bacteria liquid are prepared into a solution, and then the microbial nutrient and foaming agent are sequentially a...

Embodiment 2

[0048]1. Composition of microbial-assisted air foam system: microbial nutrient, fermentation broth, and air foam system.

[0049] 1. Composition of microbial nutrient: diammonium hydrogen phosphate (industrial product), 0.4%; sodium nitrate (industrial product) 0.3%; yeast powder (industrial product) 0.1%, corn steep liquor dry powder (industrial product) 0.4%, and the rest is water .

[0050] 2. Microbial fermentation liquid: aerobic bacteria (mainly hydrocarbon oxidizing bacteria), the concentration of the fermentation liquid is 5×10 8 pieces / ml.

[0051] 3. Composition of air foam system: air; foaming agent (industrial product) 0.5%, and the rest is water.

[0052] 2. Experimental method

[0053] The experimental method is the same as the experimental method and materials in Example 1.

[0054] 3. Experimental results

[0055] The half-life of the air foam is 117 minutes, and the foaming rate is 446%. The oxygen content in the gas produced at the outlet of the core is...

Embodiment 3

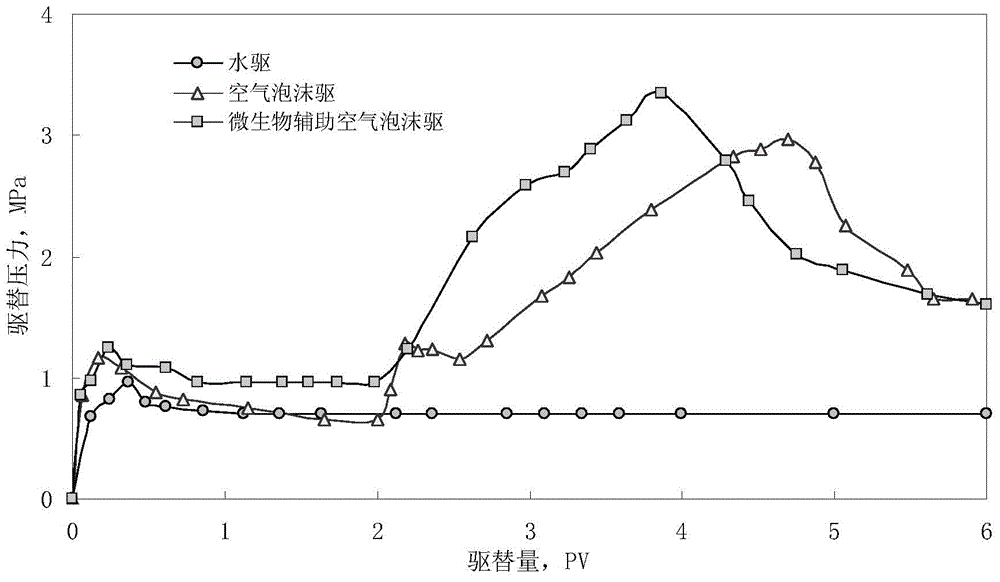

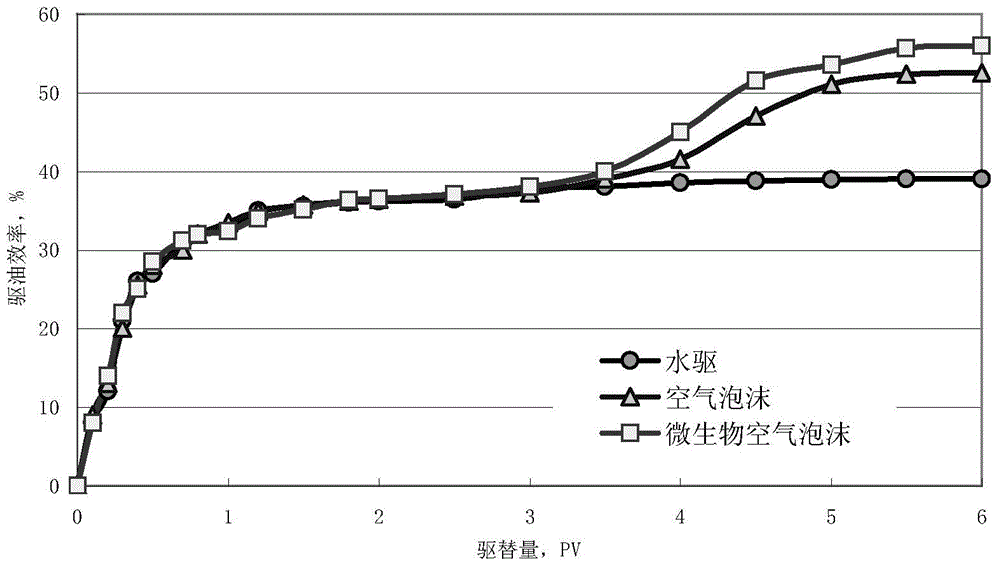

[0060] This example is to test the influence of air foam flooding and microbe-assisted air foam flooding on oil displacement efficiency and the change of displacement pressure (that is, the plugging ability of air foam to core macropores).

[0061] 1. Composition of microbial-assisted air foam system: microbial nutrient, fermentation broth, and air foam system.

[0062] 1. Composition of microbial nutrient: diammonium hydrogen phosphate (industrial product), 0.3%; sodium nitrate (industrial product) 0.2%; yeast powder (industrial product) 0.07%, corn steep liquor dry powder (industrial product) 0.3%, and the rest is water .

[0063] 2. Microbial fermentation liquid: aerobic bacteria (mainly hydrocarbon oxidizing bacteria), the concentration of the fermentation liquid is 5×10 8 pieces / ml.

[0064] 3. Air foam system composition: air; foaming agent (industrial product) 0.4%, and the rest is water.

[0065] 2. Experimental method

[0066] The oil-removed and dried oil reservo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap