Method for monitoring rock burst dangerousness in coal underground mining process

A technology of rock burst and underground mining, which is applied in surveying, mining equipment, mining equipment, etc., can solve the problems of high input cost, inconvenient on-site construction, and error in monitoring results, and achieve safe mining, low equipment cost, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The sensor model of the radon gas measurement adopted in the embodiment of the present invention is the FD-3017A type RaA radon detector.

[0031] The technical solution of this embodiment is carried out according to the following steps:

[0032] (1) Arrange detection holes for radon concentration monitoring:

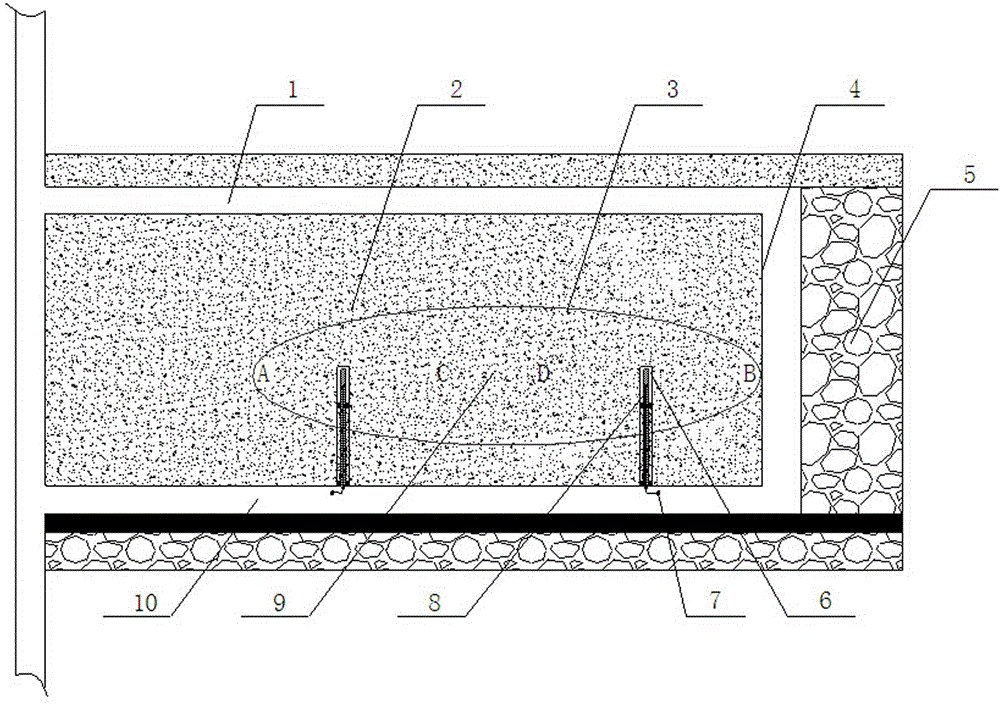

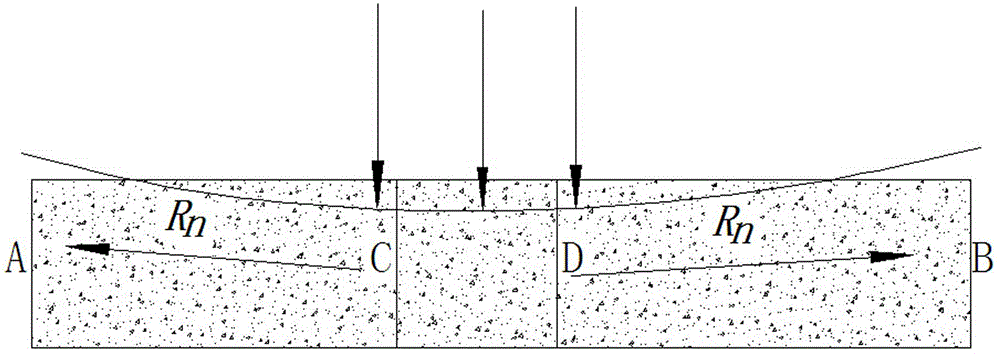

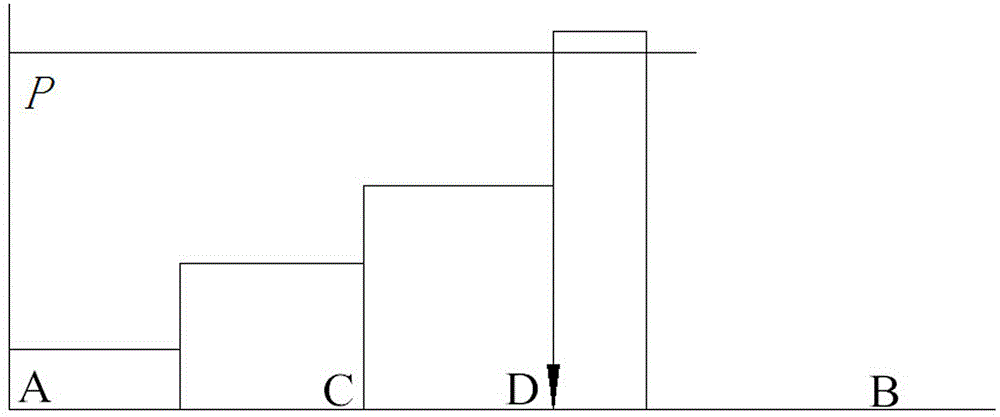

[0033] A complete mining system working face is formed during the underground mining of coal mines, such as figure 1 As shown, it includes the complete upper channel 1, the lower channel 10, the goaf 5, the working face 4 and the coal body 2. According to the stress distribution characteristics of the mining system, a strong rock burst dangerous area 3 is formed, and divided into Compression area CD and unload area AC, BD;

[0034] Two detection holes 6 are arranged on both sides of the strong rock burst dangerous area 3, the first detection hole is arranged at a distance of 60m from the working face, the second detection hole is arranged at a distance of 250m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com