Lubricant powder drying device support

A technology of drying equipment and lubricating powder, which is applied in drying, lighting and heating equipment, and drying solid materials, etc., which can solve the problems of staff's hearing impact and noise generation, and achieve the effect of avoiding irreversible deformation and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

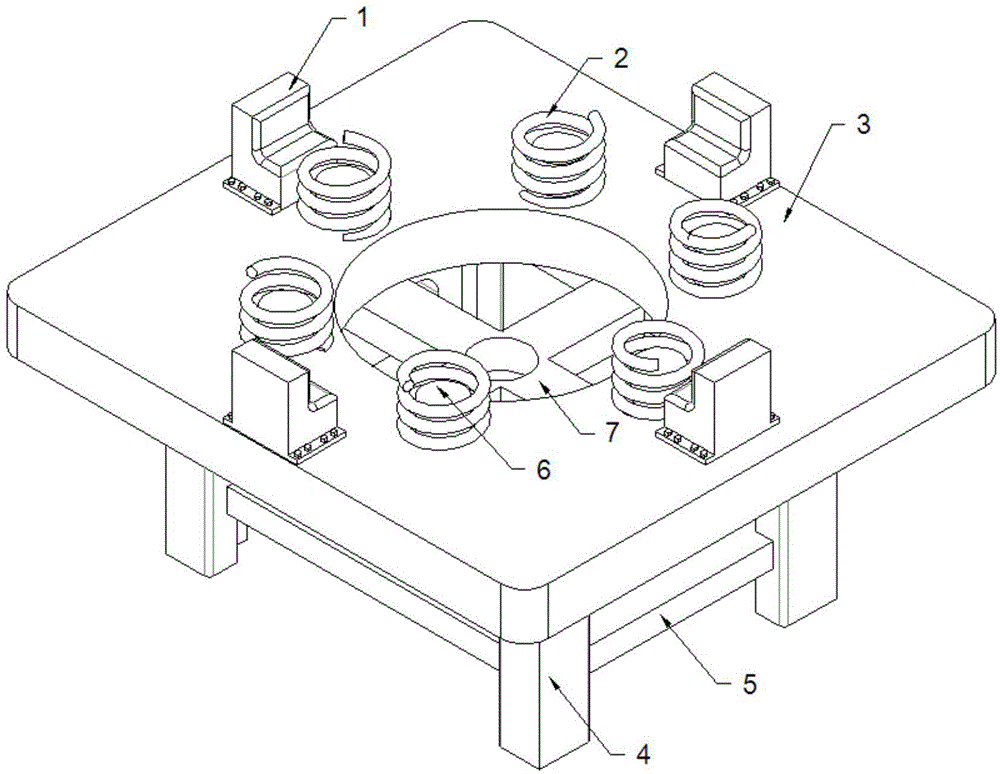

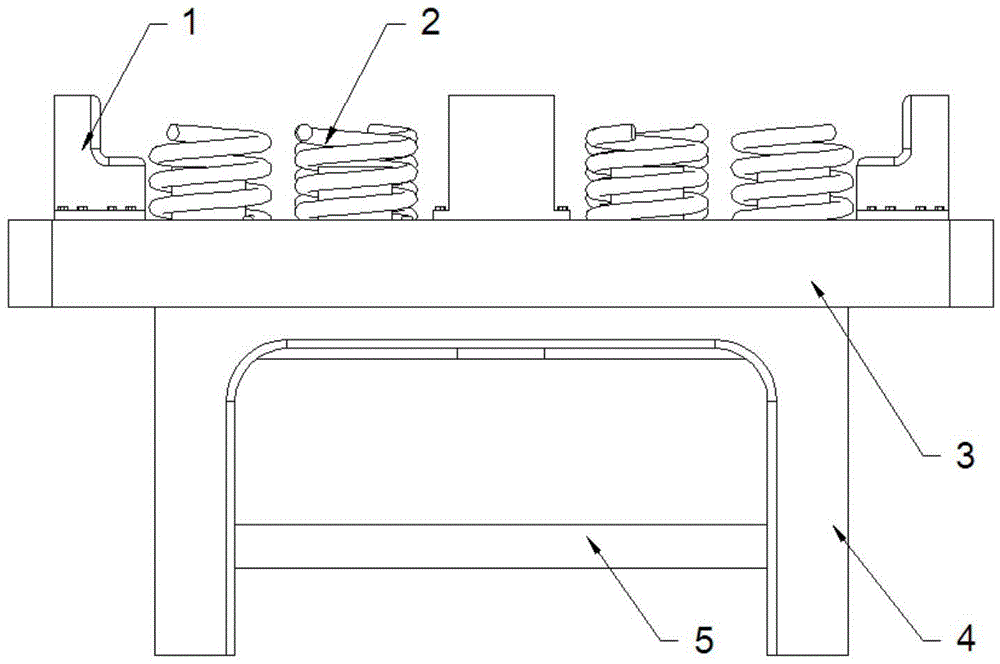

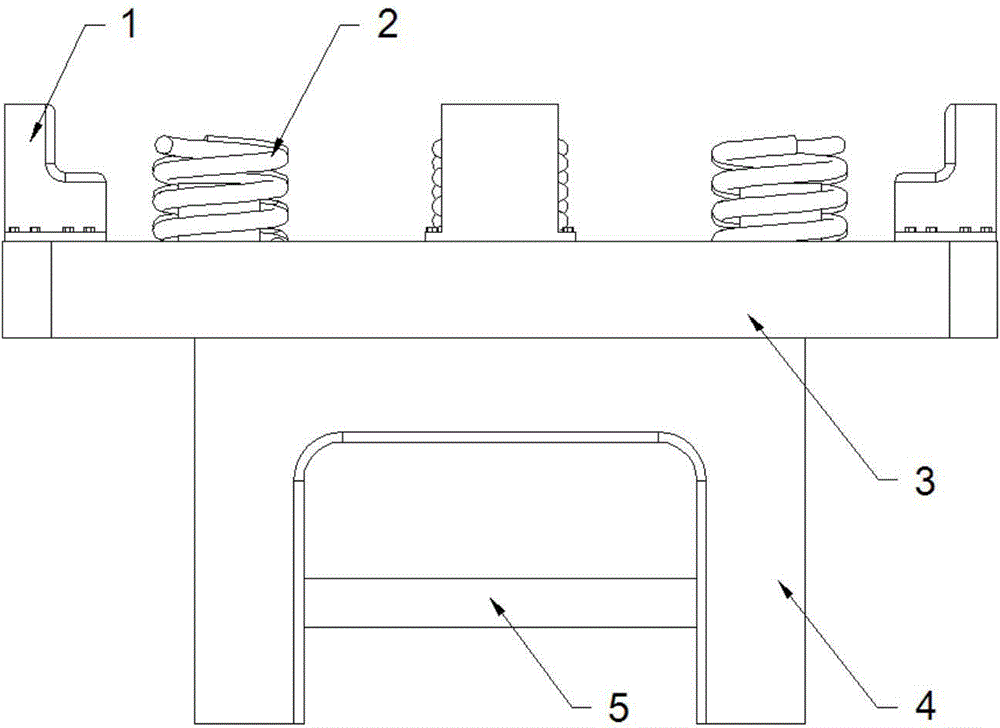

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] Such as Figure 1-4 As shown, a lubricant powder drying equipment support includes an installation platform 3 for fixing the lubricant powder drying equipment and a support column 4 for supporting the installation platform 3 . The support column 4 is fixedly connected to the lower end surface of the installation platform 3, and the center position of the upper end surface of the installation platform 3 is provided with a hole, and the outer circumference of the hole is provided with a plurality of buffer members 2, and the buffer member 2. Several limit blocks 1 are also fixedly installed on the outer periphery.

[0025] In order to reduce the production cost, the buffer member 2 in this specific embodiment is a spring. In order to optimize the cushioning effect of the springs, the number of the springs is six and form a circular arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com