An airtight detection device

A technology for air tightness detection and air source device, which is applied in measuring devices, fluid tightness testing, measuring instruments, etc., can solve the problems of high cost and low application rate of low-end equipment, achieve low cost, improve processing accuracy, The effect of meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

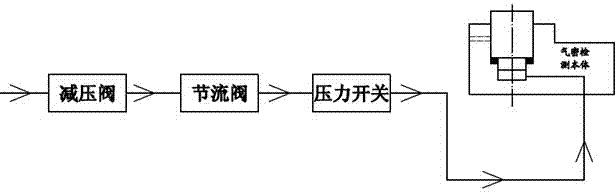

[0023] The air-tight detection device of the present invention includes an air pressure detection device, an air guide tube, a detection base and a contact; the detection base is connected to the air pressure detection device through an air guide tube, and an L-shaped vent hole is arranged in the detection base, and a vertical section of the L-shaped vent hole is arranged The contact; the side wall of the contact is provided with a limit groove, the side wall of the detection base is provided with a limit bolt hole, and the limit bolt is inserted into the limit groove through the limit bolt hole; a sealing ring is installed at the bottom of the contact, The sealing ring is used to close the gas path when the device is working. The structure of the limit groove on the contact is a waist-shaped groove, and there is a movable gap between the limit bolt and the waist-shaped groove, which can limit and standardize the up and down travel of the contact, so that the limit position of ...

Embodiment 2

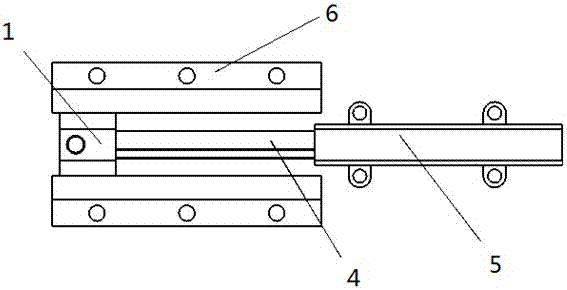

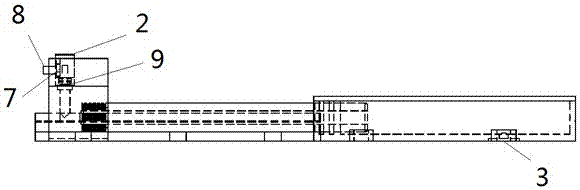

[0027] Such as figure 2 and image 3 , the airtight detection device of this example includes an air pressure detection device, an air guide tube, a detection base and a contact; 5, and sealed with two sealing rings, this structure ensures that the present invention can detect workpieces with different sizes, and adopts the structural form of a sliding cylinder to meet the moving requirements under the condition of limited space; the other end of the hollow air rod 4 is connected to the L The horizontal section of the air-shaped air hole is connected; and the cylinder body 5 is connected with the gas path of the air pressure detection device through the air inlet hole 3; the hollow air rod is connected with the detection base through a tapered thread; The fixture is connected to the test fixture by bolts; there are slide rails 6 on both sides of the detection base 1, and the two sides of the detection base 1 are compatible with the slide rails 6. The slide rails 6 are used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com