Liquid floated pendulum type accelerometer temperature control model parameter identification method

A technology of accelerometer and liquid floating pendulum, which is applied in the direction of temperature control, adaptive control, general control system, etc., can solve the problems that the research on the parameter identification of the pure delay link has not been reported publicly, and it stays in the first-order inertia model, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

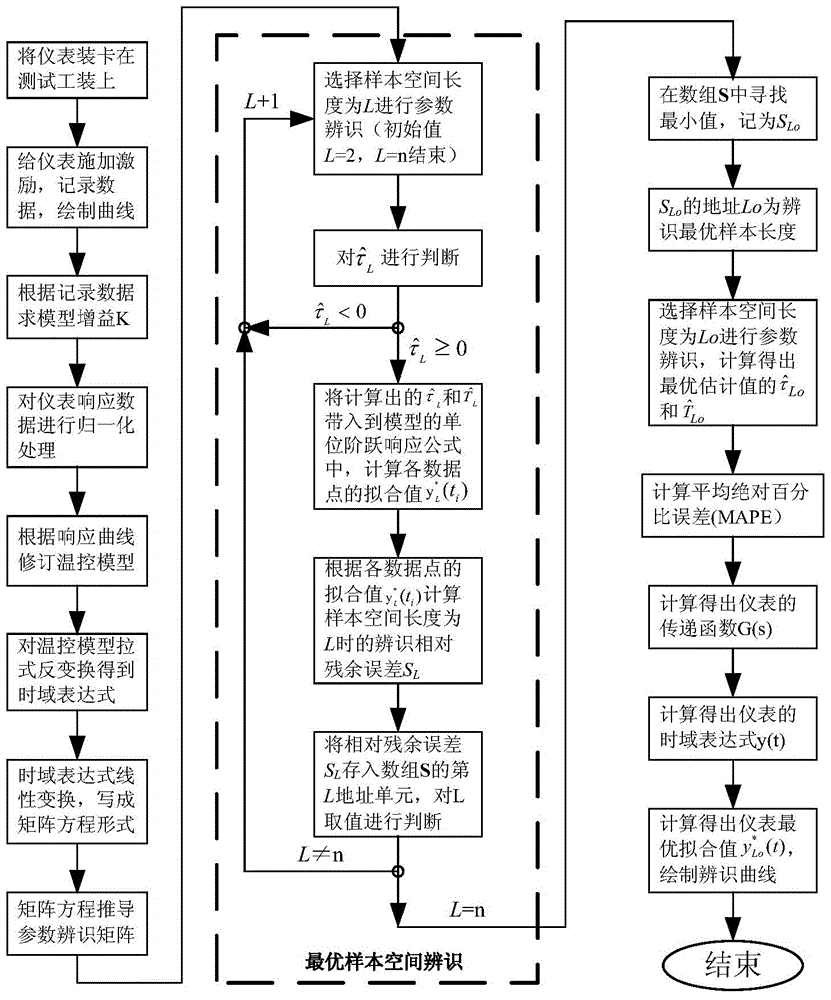

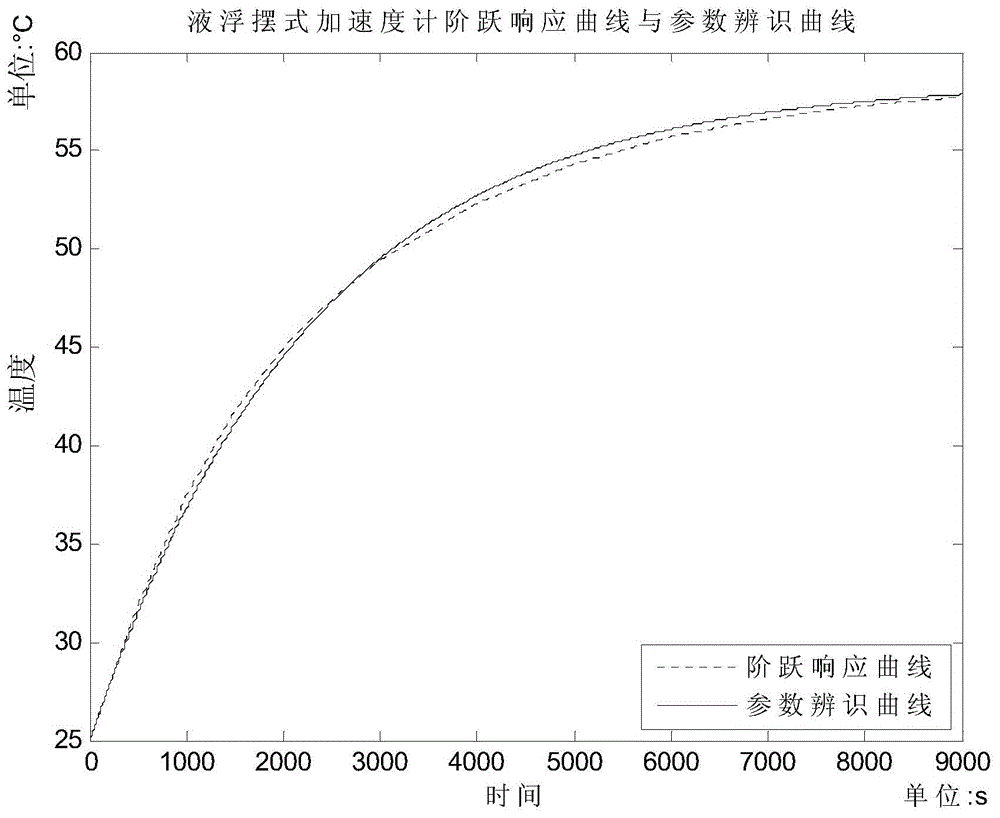

[0062] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0063] Under certain high-precision operating conditions, the temperature control accuracy of the liquid-floating pendulum accelerometer is required to be within ±0.1°C. However, due to the restrictive factors of this type of instrument in terms of volume and structure, the heating device and the thermal sensor are at a certain distance, resulting in a certain time delay for the temperature generated by the heating device to be transmitted to the thermal sensor, which affects the accuracy and accuracy of the temperature control system. impact on stability.

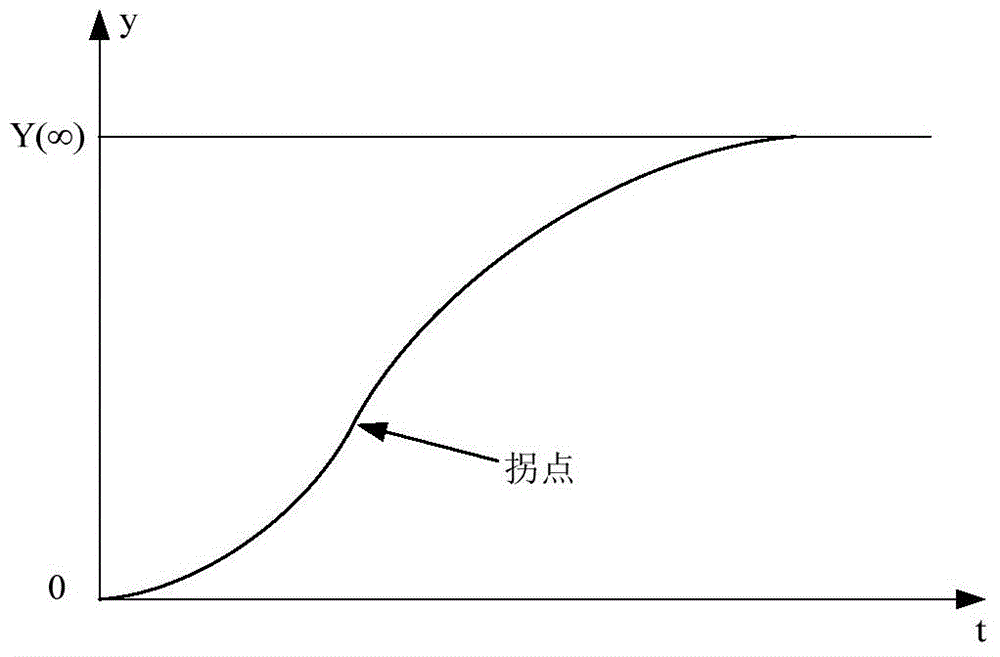

[0064] A temperature control model parameter identification method for a liquid floating pendulum accelerometer in the present invention is mainly composed of three parts: the instrument testing stage, the model modeling stage and the parameter identification stage. The steps are as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com