Electric wire clamp

A wire and wire technology, applied to the field of special tooling for wire harness production, can solve the problems of inconvenient adjustment of clamping size, easy damage to wires, unstable clamping, etc. Fast and stable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

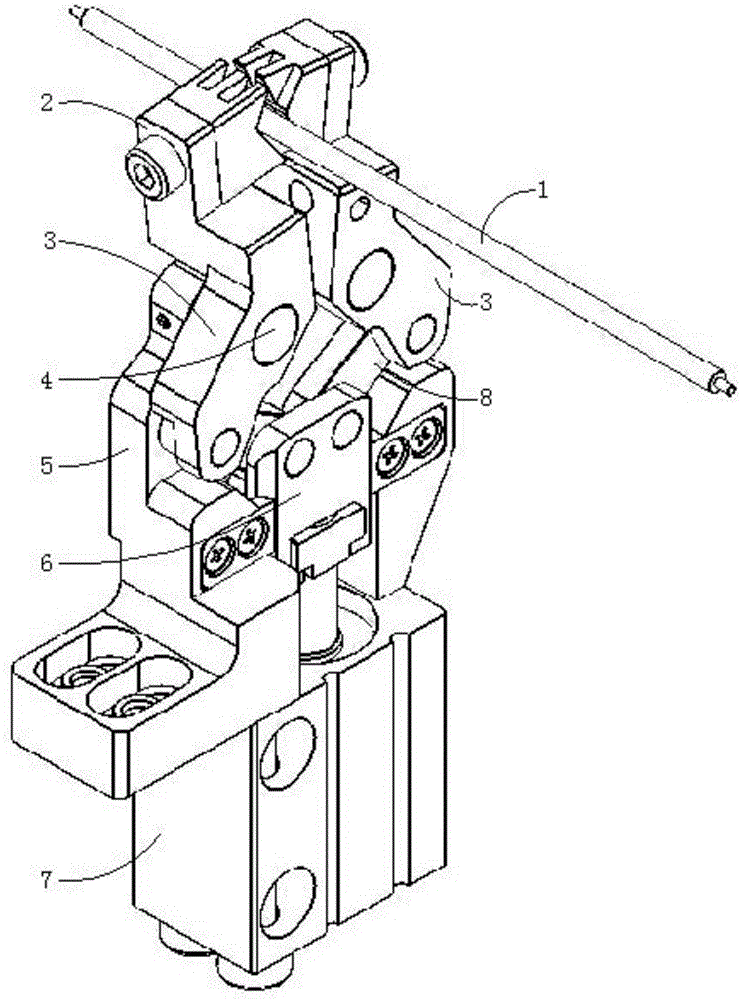

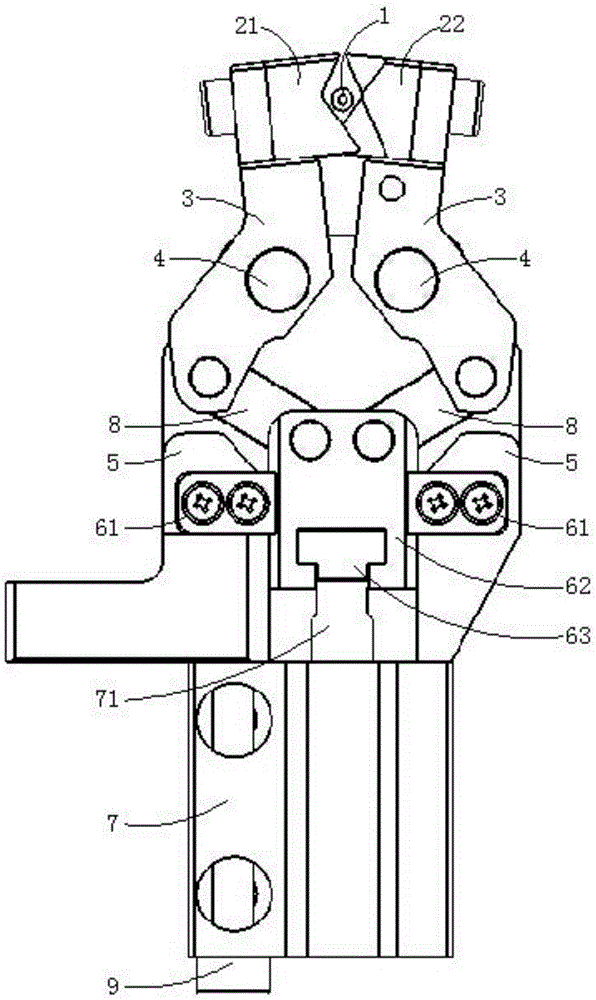

[0025] Such as Figure 1 to Figure 5 As shown, the wire clamp of this embodiment includes a clamping mechanism 2 composed of a left clamping part 21 and a right clamping part 22, two symmetrically arranged rotating rods 3, a base 5, a cylinder 7 and two connecting rods 8 .

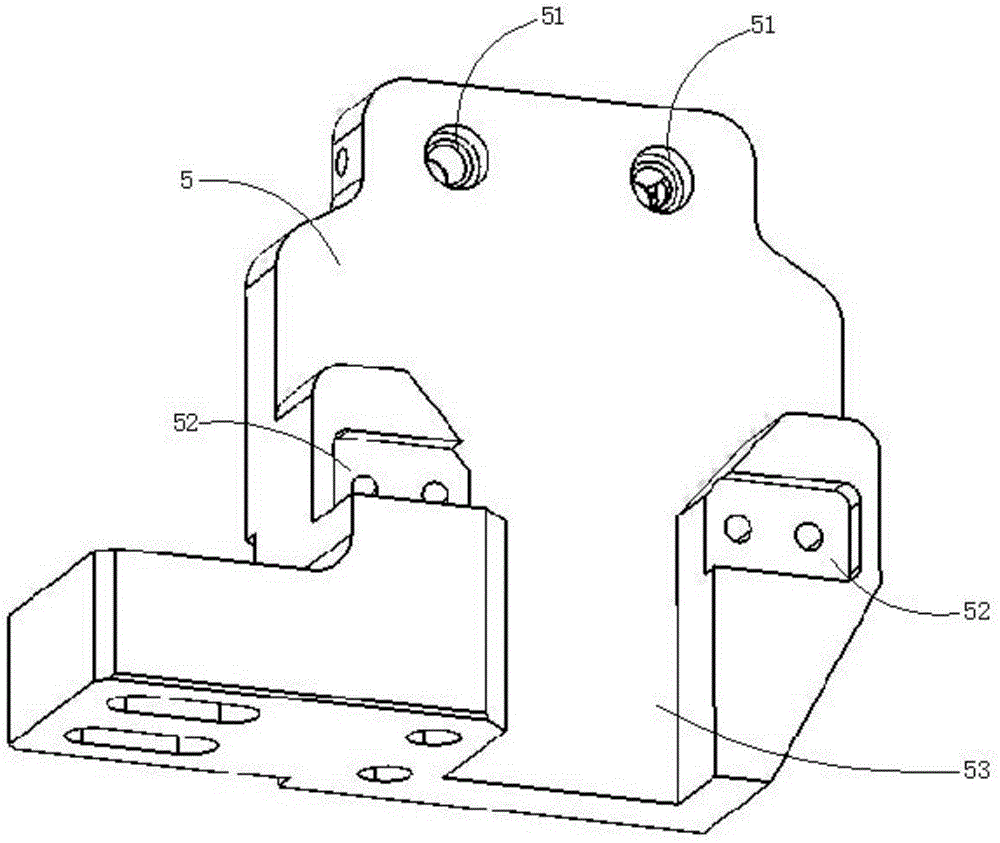

[0026] The lower end of base 5 is provided with transmission block chute 53, and the base 5 above transmission block chute 53 is provided with two bearing pins-mounting hole 51, and the groove wall of transmission block chute 53 left and right sides is respectively fixedly provided with limit position. Block 61. The lower end of the base 5 is fixedly connected with the cylinder 7 through a fixing bolt 9 .

[0027] The middle parts of the two rotating rods 3 are respectively hinged with the base 5 through a pin shaft-4, and the two pin shafts-4 are installed in the two pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com