a cutting tool

A technology of cutting tools and cutting blades, applied in cutting blades, tools for lathes, turning equipment, etc., can solve the problems of blade four-point contact failure, complex structure, poor reliability, etc., achieve reliable positioning, improve machining accuracy, The effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

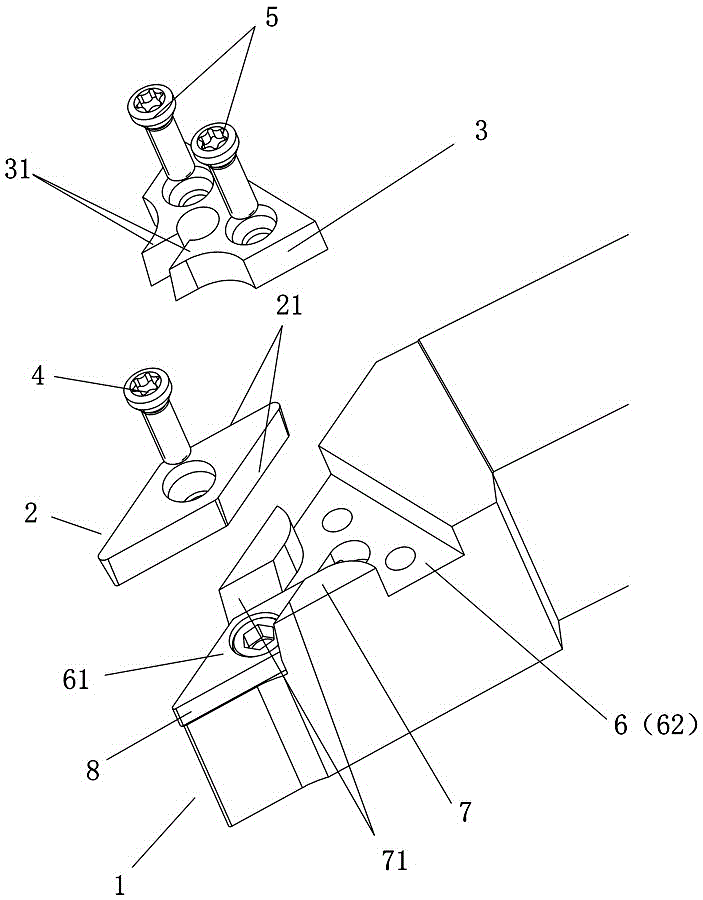

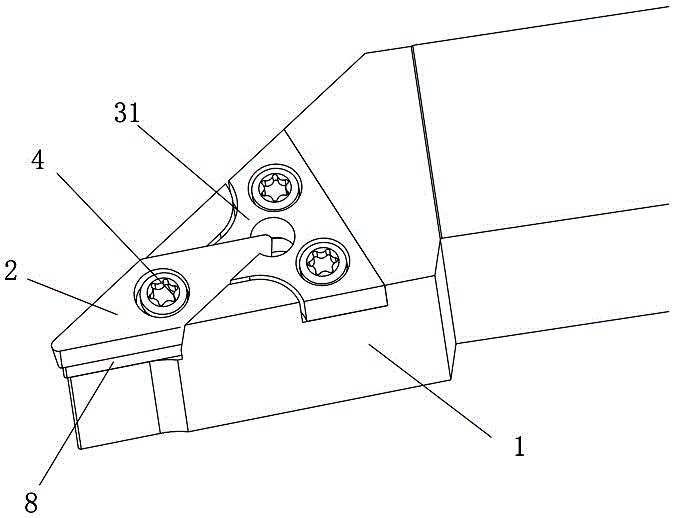

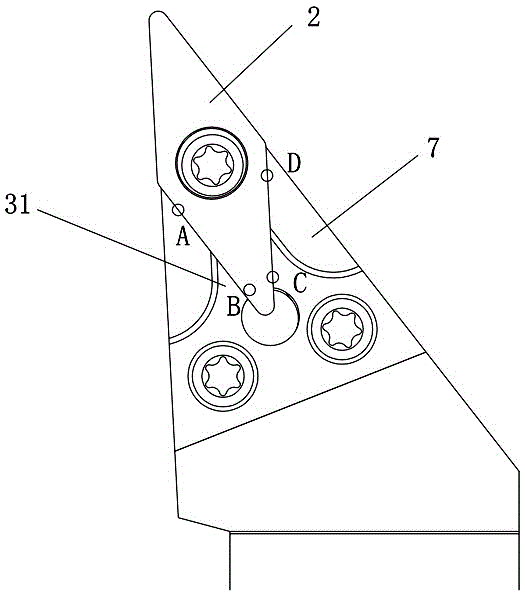

[0025] Figure 1 to Figure 4 Shown is an embodiment of the cutting tool of the present invention, the cutting tool includes a cutter body 1, a cutting blade 2 and a positioning plate 3, the head of the cutter body 1 is provided with a sipe 6, and the sipe 6 includes a communicating blade receiving groove 61 and the positioning plate accommodation groove 62, the cutting blade 2 is installed in the blade accommodation groove 61 through the first fastening screw 4, the positioning plate 3 is installed in the positioning plate accommodation groove 62 through the second fastening screw 5, and the positioning plate 3 is provided with An elastic positioning claw 31 that is in contact with one of the side positioning surfaces 21 of the cutting blade 2 and can be elastically deformed. A positioning flank plate 7 that is in contact with the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com