Wings and transmission mechanism of ornithopter

A transmission mechanism and flapping-wing aircraft technology, applied in the field of general aviation, can solve the problems of incomplete understanding of the nature of flapping-wing flight, inability to reflect the aerodynamic advantages of flapping-wing flight, and the inability to reflect the advantages of flapping-wing flight, etc., to achieve concealment Good effect, reduced flight resistance, wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

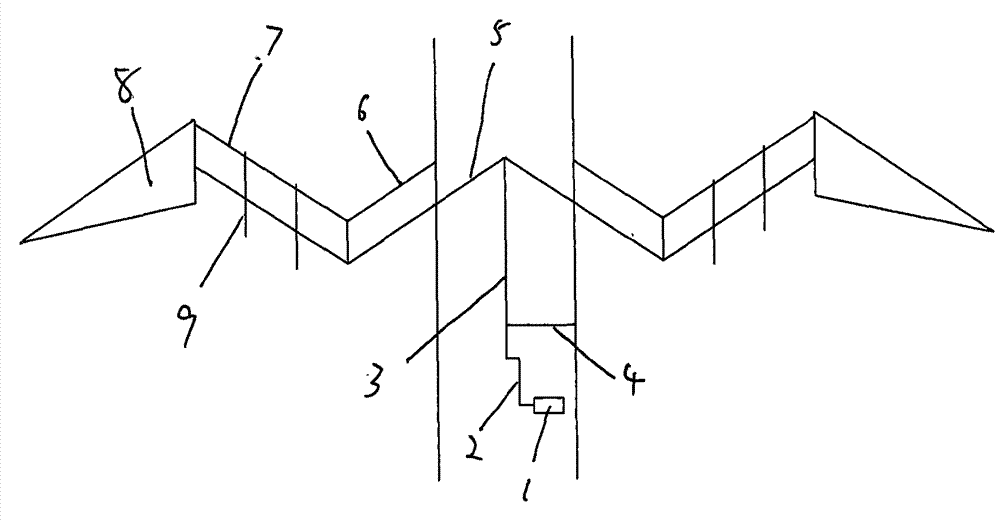

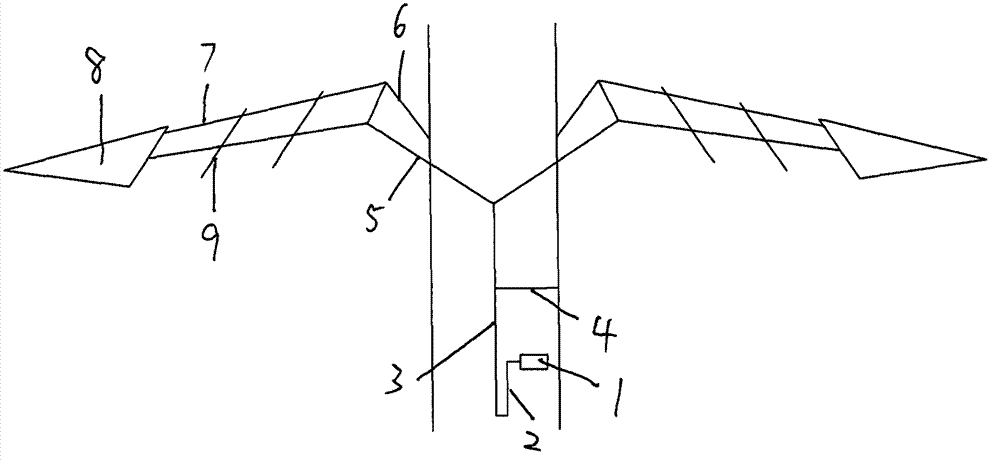

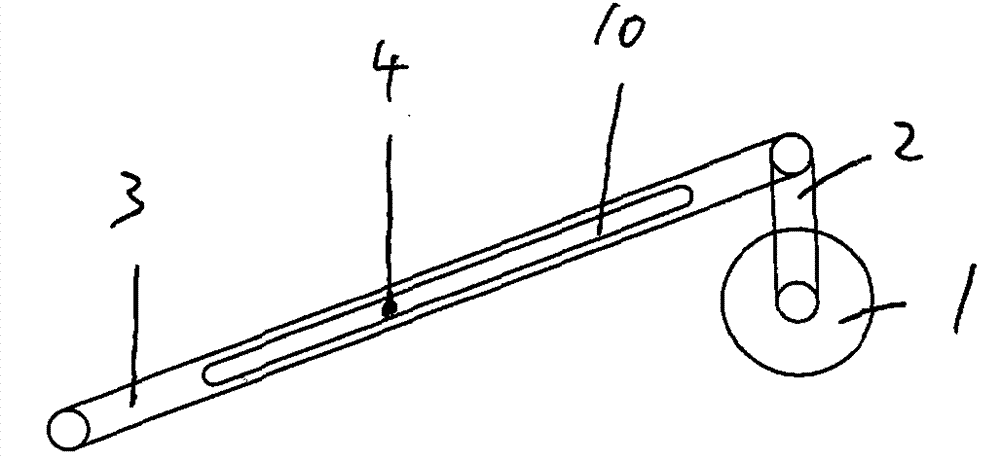

[0013] The wing and the transmission mechanism of the orthopter are composed of a motor, a crankshaft, a connecting rod, a stator, an inner wing section skeleton, a middle wing section skeleton and an outer wing section. In the figure, the motor is connected to the crankshaft, and the crankshaft is connected to the connecting rod. There is a gap in the middle of the connecting rod. One end of the stator is fixed on the fuselage, and the other end passes through the gap in the middle of the connecting rod. One end inside the fuselage, the rear frame of the inner wing section passes through the fuselage outwards, and a point connected to the fuselage is used as a fulcrum, and the outer end of the rear frame of the inner wing section is connected to the inner side of the variable diamond-shaped rectangular frame of the middle wing section The apex of the lower end, the inner side of the front frame of the inner wing section is connected to the fuselage, and the outer end is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com