Lifting electro-optical device

A technology of optoelectronic devices and optoelectronic eyes, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of reducing the life of cylinders and wearing parts, increasing the labor intensity of operators, and the loss of compressed gas, reducing labor Strength, reduce equipment maintenance rate, reduce the effect of stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

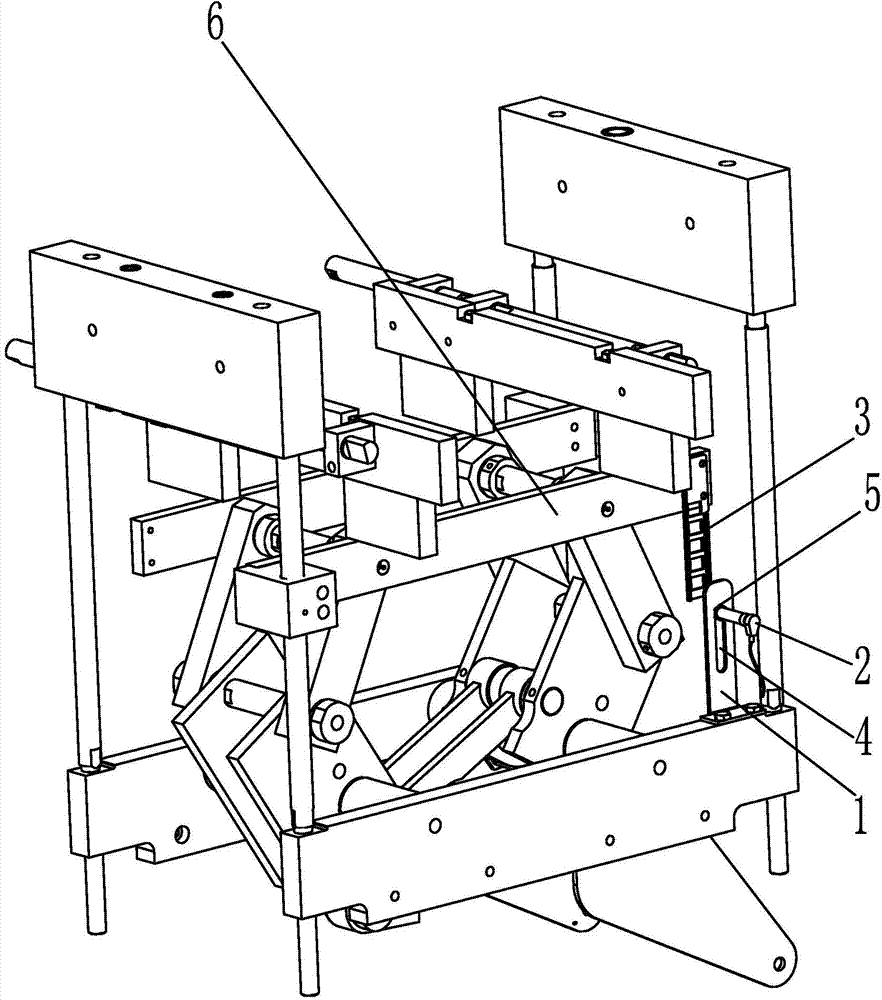

[0009] Such as figure 1 As shown, the technical solution adopted in the present invention is: a lifting photoelectric device, comprising a photoelectric eye fixing seat 1, a photoelectric eye 2 and a porous photoelectric detection plate 3, and the photoelectric eye fixing seat 1 is fixed on a fully automatic stretch film packaging machine , the upper end is provided with an oval mounting hole 4, the photoelectric eye 2 is installed in the oval mounting hole 4 through the bolt 5 located at its bottom, and the photoelectric eye 2 can slide up and down in the oval mounting hole 4, so The porous photoelectric detection plate 3 is fixed on the lifting plate 6 .

[0010] Through the above settings, when the present invention is working, when the lifting plate 6 moves up and down, the photoelectric eye 2 can accurately receive the position of the lifting plate 6 through the porous form on the porous photoelectric detection plate 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com