Silicon PU type synthetic court

A technology for courts and plastics, applied in coatings, buildings, roads, etc., can solve problems such as the base surface of the court is easy to sag, lack of sports texture, and the court is easy to slip, so as to improve the level of competition, reduce construction technical requirements, and facilitate construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

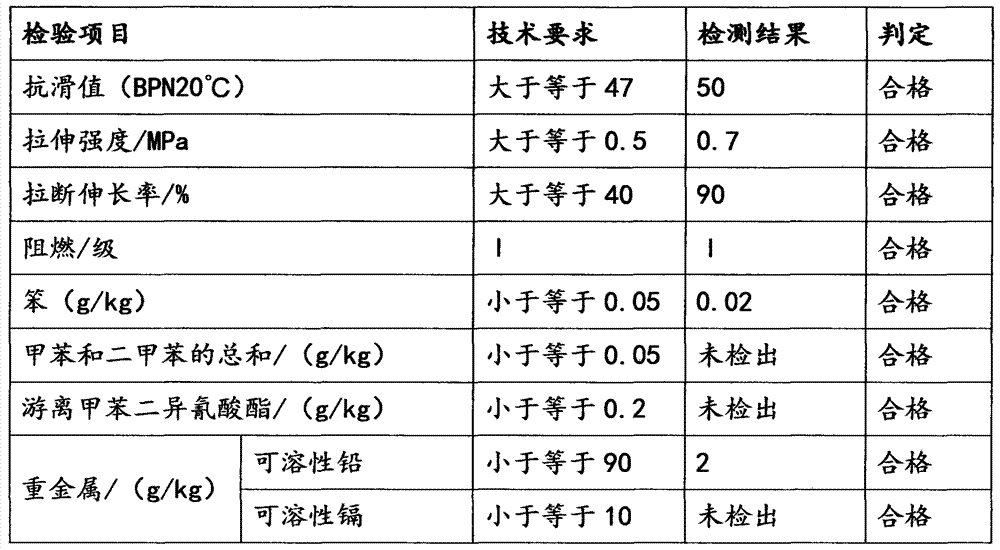

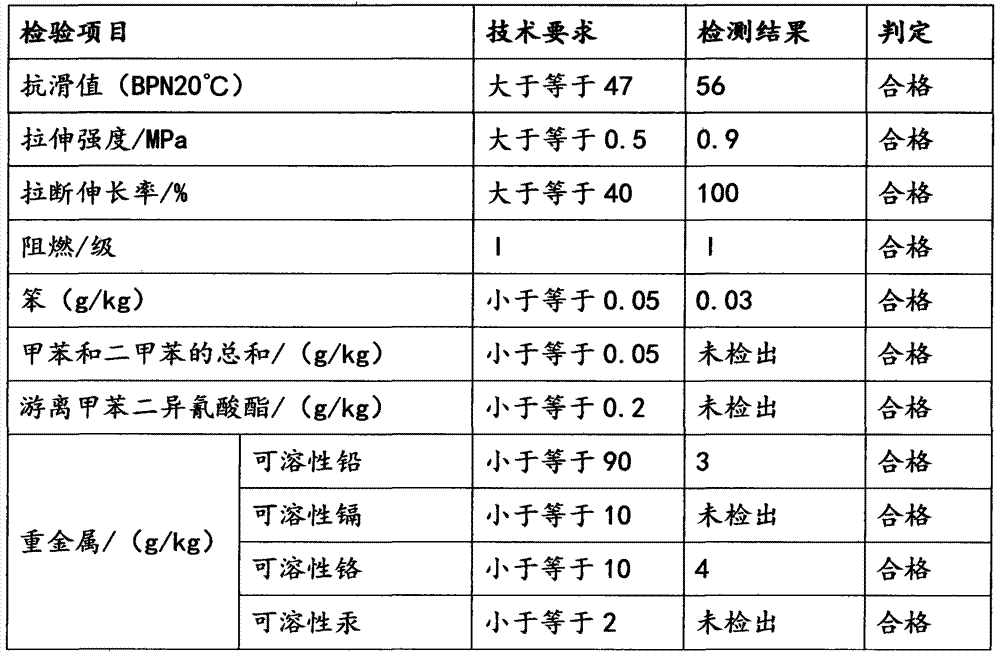

Embodiment 1

[0015] The silicon PU type plastic court includes a base layer, a waterproof layer, a silicon PU elastic layer and a finish paint protective layer. The silicon PU elastic layer is composed of a leveling layer and a strengthening layer, and the construction is carried out according to the following steps.

[0016] a. Base layer treatment: clean the asphalt concrete foundation and cement concrete foundation, then rinse with 7-9% hydrochloric acid aqueous solution, rinse with clean water, then dry, and finally fill the expansion joint with silicon PU elastic material ;

[0017] b. Waterproof layer: roll-coat the silicon PU primer on the base layer, and roll-coat 0.15kg to 0.25kg of silicon PU primer per square meter;

[0018] c. Silicon PU elastic layer: add 10-20% quartz sand to the silicon PU elastic material, mix and stir evenly, and then apply it on the waterproof layer with a rake or trowel to form a leveling layer. After the leveling layer is dry, Use the water accumulatio...

Embodiment 2

[0027] The silicon PU type plastic court includes a base layer, a waterproof layer, a silicon PU elastic layer and a finish paint protective layer. The silicon PU elastic layer is composed of a leveling layer and a strengthening layer, and the construction is carried out according to the following steps.

[0028] a. Base layer treatment: clean the asphalt concrete foundation and cement concrete foundation, then rinse with 7-9% hydrochloric acid aqueous solution, rinse with clean water, then dry, and finally fill the expansion joint with silicon PU elastic material ;

[0029] b. Waterproof layer: roll-coat the silicon PU primer on the base layer, and roll-coat 0.15kg to 0.25kg of silicon PU primer per square meter;

[0030] c. Silicon PU elastic layer: add 10-20% quartz sand to the silicon PU elastic material, mix and stir evenly, and then apply it on the waterproof layer with a rake or trowel to form a leveling layer. After the leveling layer is dry, Use the water accumulatio...

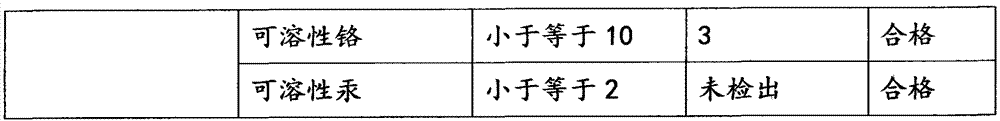

Embodiment 3

[0039] The silicon PU type plastic court includes a base layer, a waterproof layer, a silicon PU elastic layer and a finish paint protective layer. The silicon PU elastic layer is composed of a leveling layer and a strengthening layer, and the construction is carried out according to the following steps.

[0040] a. Base layer treatment: clean the asphalt concrete foundation and cement concrete foundation, then use 7-9% hydrochloric acid aqueous solution for medium washing, rinse with clean water, then dry, and finally inject silicon PU elastic material into the expansion joints fill;

[0041] b. Waterproof layer: roll-coat the silicon PU primer on the base layer, and roll-coat 0.15kg to 0.25kg of silicon PU primer per square meter;

[0042] c. Silicon PU elastic layer: add 10-20% quartz sand to the silicon PU elastic material, mix and stir evenly, and then apply it on the waterproof layer with a rake or trowel to form a leveling layer. After the leveling layer is dry, Use th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com