Thickened oil injection and recovery integrated complete device comprising all metal screw pump

A screw pump, all-metal technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of inability to meet high temperature, unsuitable for high temperature oil wells, cumbersome operation, etc., to simplify the steam injection huff and puff process, The effect of shortening the turnaround time and extending the thermal recovery period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

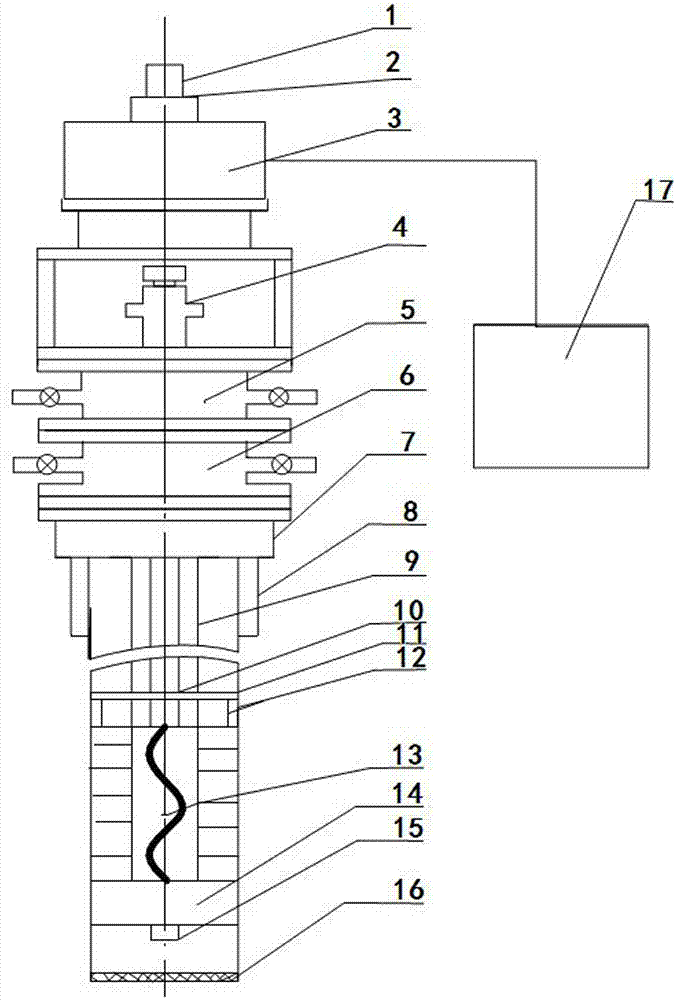

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] All metal screw pump heavy oil injection and production integrated device, including: polished rod assembly 1, permanent magnet motor drive head protection device 2, direct drive three-phase permanent magnet synchronous motor 3, high temperature and high pressure sealing assembly 4, special steam injection device 5 , oil pipe head 6, casing head 7, surface casing 8, oil pipe 9, torque rod 10, torque anchor 12, metal screw pump 13, centralizer 14, tail pipe 15, screw pump ground control cabinet 17; from top to bottom The following are polished rod assembly 1, permanent magnet motor drive head protection device 2, direct drive three-phase permanent magnet synchronous motor 3, high temperature and high pressure sealing assembly 4, special steam injection device 5, oil pipe head 6, bushing, torque rod 10 , torque anchor 12, centralizer 14, stern pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com