Thermal production well filling vapor and nitrogen foam profile control technique

A technology of nitrogen foam and process method, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., which can solve the problems of reducing the efficiency and effect of heavy oil thermal recovery, reducing the effective steam sweep area, and decreasing the periodic oil-gas ratio. , to improve the effect of heat insulation, improve the effect of throughput and recovery, and reduce the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] 1. Performance requirements of foaming agent

[0022] 2. Adaptation conditions

[0023] (1) The reservoir has strong heterogeneity. Since foam is mainly produced in the large pores of the sand layer, oil layers with higher permeability are selected;

[0024] (2) Blocks with active side and bottom water and heavy oil wells with integrated water content> 90%.

[0025] (3) After multiple huffs and puffs, a steam channel is formed, and the remaining oil is abundant within the steam heating radius;

[0026] (4) According to the test, when the steam flooding residual oil saturation (18.2%) is below, it starts to have a higher plugging capacity, so oil wells with low oil saturation and high permeability strips are selected;

[0027] (5) The thickness of the oil layer ≥ 5 meters;

[0028] (6) The downhole casing is intact.

[0029] 3. Nitrogen source and injection method

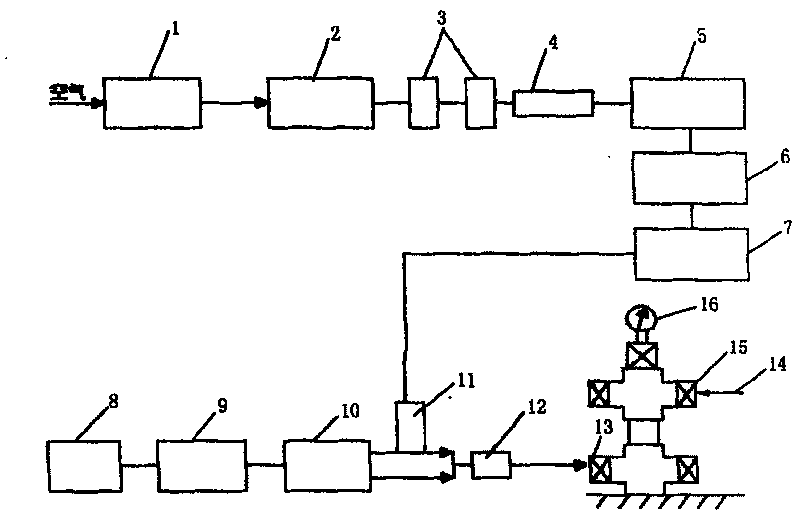

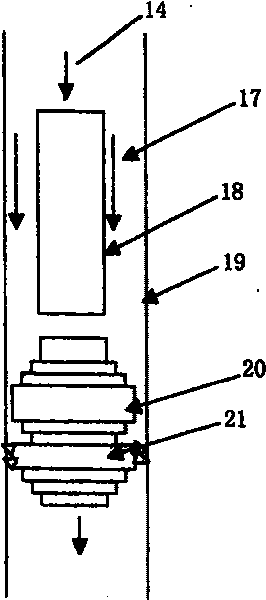

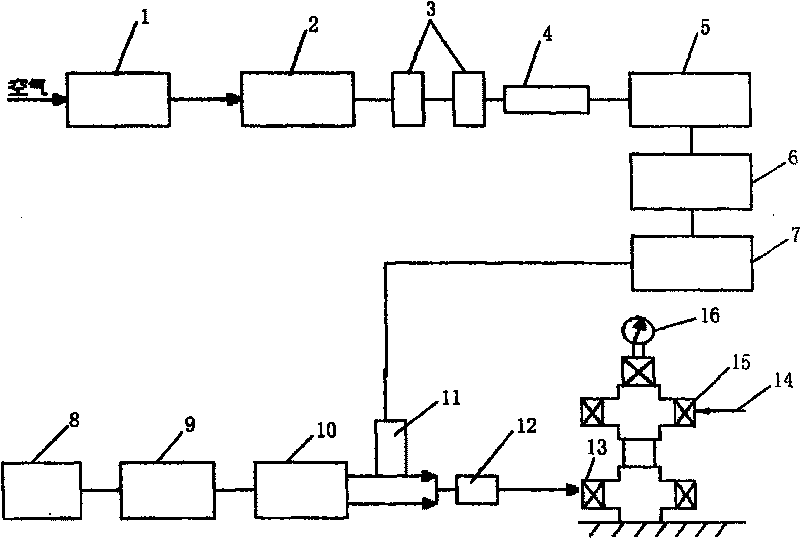

[0030] The process of using membrane air separation nitrogen car to produce nitrogen is as follows figure 1 Shown.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com