Front air guide firearm universal casing assembly

A general-purpose machine and bolt technology, applied in firearms, pistols, offensive equipment, etc., can solve the problems that the back seat of the bolt affects the shooting accuracy, and achieve the effects of improving shooting accuracy, reducing production costs, and reducing recoil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

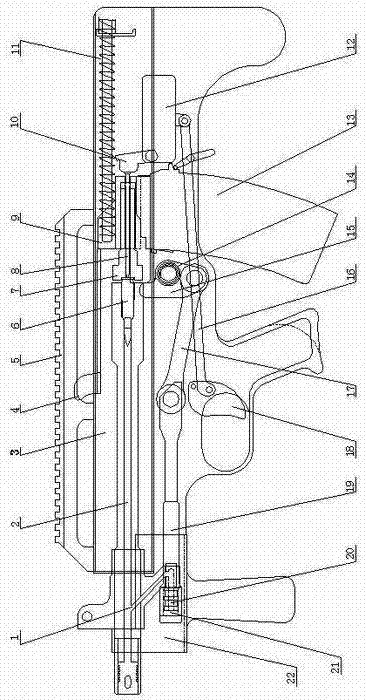

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0010] As shown in the figure, an axial gun barrel 2 is installed in the casing 3, and a guide rod sheath 22 is installed on the lower side of the front end of the casing 3, and a rear guide rod 19 is installed in the guide rod sheath 22, and the guide rod 19 A cavity air chamber 21 is left inside the front section of the air chamber 21, and an axial nozzle 20 is housed in the air chamber 21. An air guide hole 1 communicated with the rear end 20 of the gun barrel 2 and the nozzle is left, and the rear end left side of the guide rod 19 is installed. Connecting rod 17 is arranged, and the rear end of connecting rod 17 is equipped with upper setting lever 15, and back-moving spring 14 is housed on the setting lever 15, and bolt 9 is equipped with on the rear side of the upper end of setting lever 15, and the bottom of bolt 9 Side is equipped with clip 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com