Anisotropic magnetic resistance material with NiFe alloy magnetic layer and preparation method of anisotropic magnetic resistance material

A technology of anisotropic magnetic and resistive materials, which is applied in the manufacture/processing of magnetic field-controlled resistors and electromagnetic devices, can solve problems such as unfavorable device sensitivity, AMR ratio attenuation, stability problems, etc., to reduce magnetic field sensitivity, Effect of improving coercive force and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

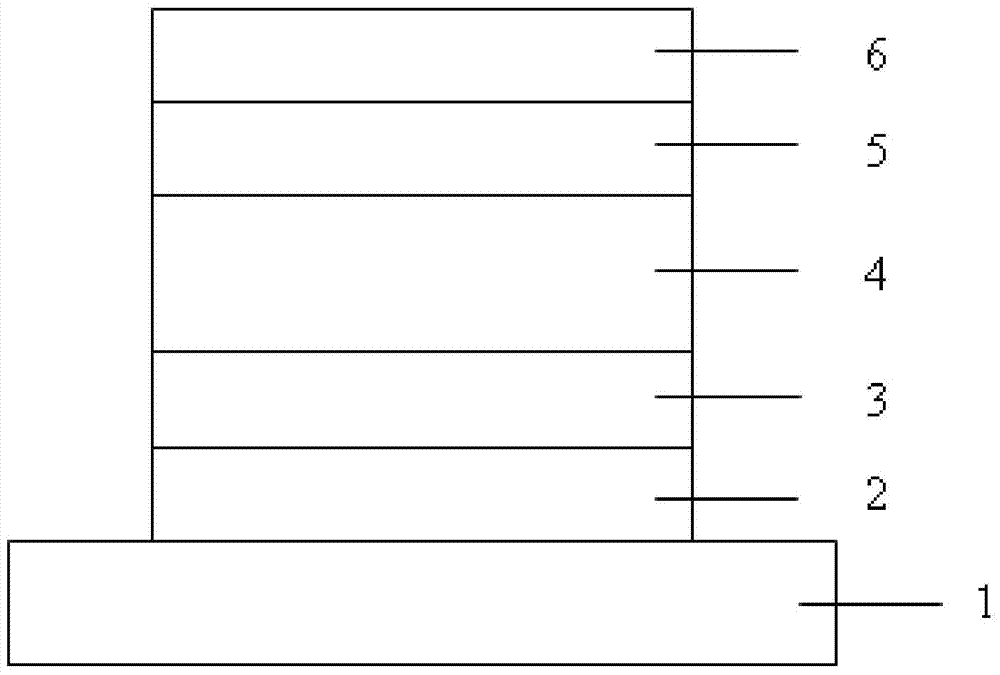

[0027] Such as figure 1 The shown anisotropic magnetoresistive material sequentially includes a thermally oxidized silicon or glass substrate 1, a Ta buffer layer 2, a first NiO pinning stabilization layer 3, a NiFe magnetic layer 4, a second NiO pinning stabilization layer 5 and Ta protective layer6.

[0028] The preparation method of anisotropic magnetoresistance material is as follows: Ta, NiO, NiFe, NiO and Ta are sequentially deposited on thermally oxidized single crystal silicon or glass substrate by magnetron sputtering technology, and the above layers correspond to the aforementioned Ta buffer Layer 2 , first NiO pinning stabilization layer 3 , NiFe magnetic layer 4 , second NiO pinning stabilization layer 5 and Ta protection layer 6 .

[0029] In step S1, the thermally oxidized single crystal silicon or glass substrate is ultrasonically cleaned with electronic cleaning solution and deionized water, and then dried for use.

[0030] Step S2, install the washed single ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap