A brush installation structure and a brush installation method

An installation structure and brush technology, applied in circuits, current collectors, electrical components, etc., can solve problems such as the inability to guarantee positive pressure, the influence of the use of electric rotary connectors, and the inability to guarantee the contact angle between the brush and the electric slip ring, etc. Improve quality and service life, ensure the effect of rotating torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

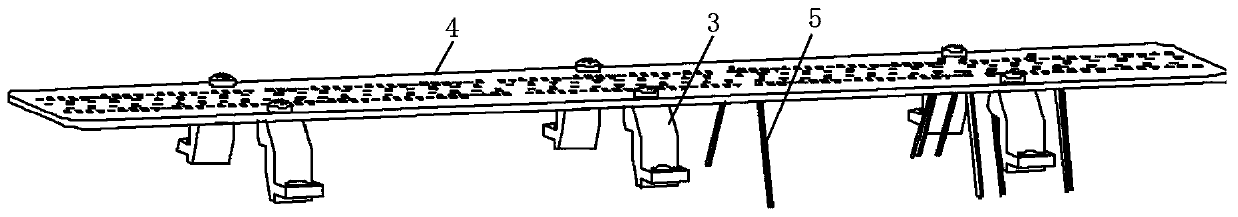

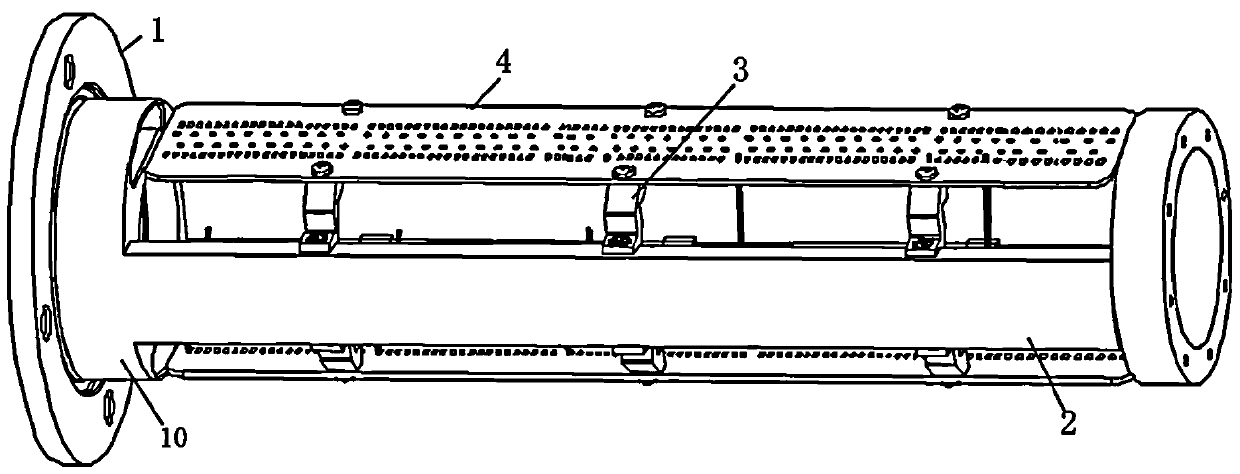

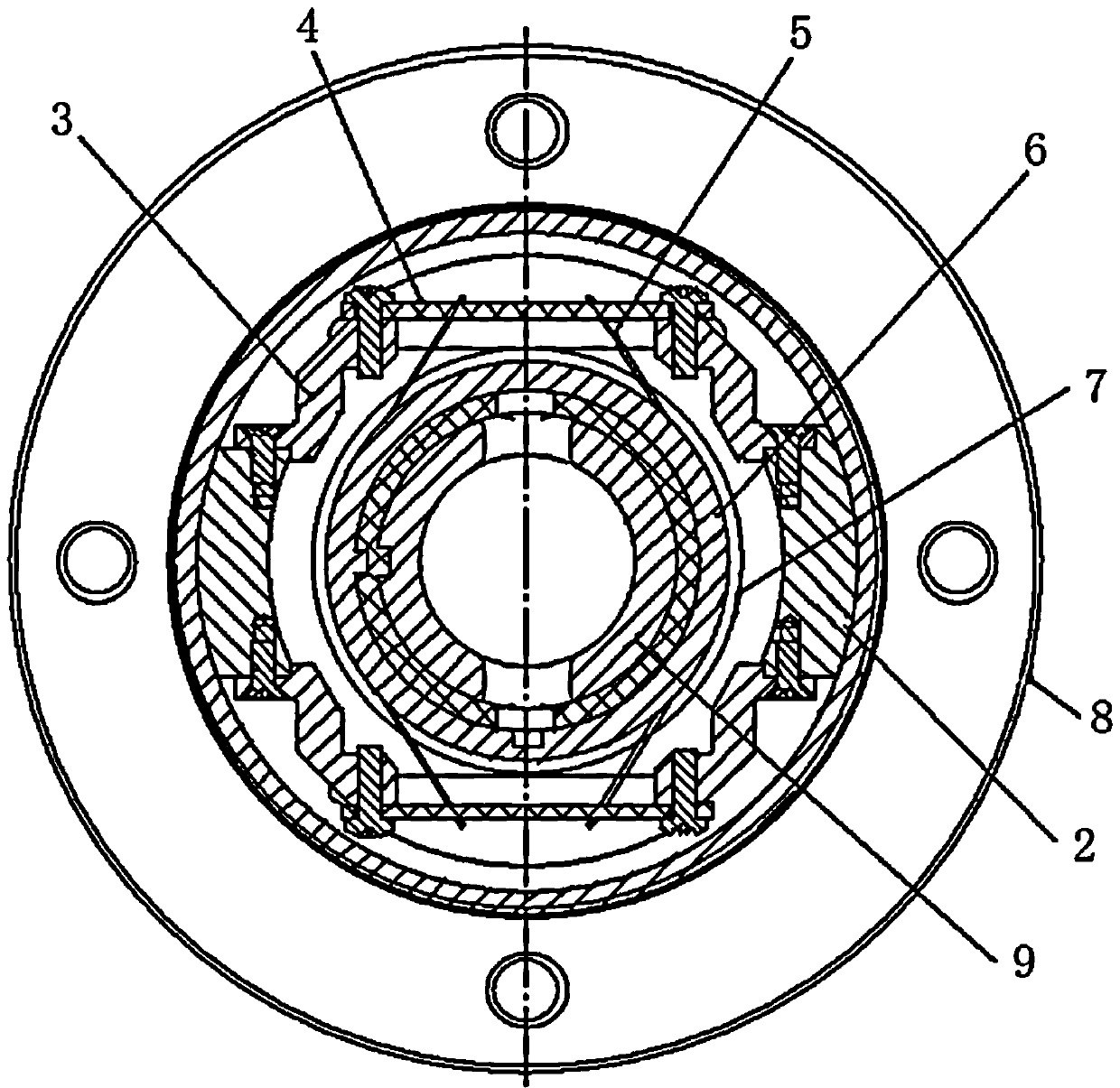

[0024] Embodiment 1 of the brush installation method of the present invention includes the following steps: the first step is to assemble the left connector of the bracket connector on the brush bracket from left to right from the left side of the left brush, and install the bracket connector The right connecting piece, which is separate from the left connecting piece, is assembled on the brush holder from the right side of the right brush from right to left; the second step is to connect the left and right connecting pieces to the connector body respectively.

[0025] Embodiment 2 of the brush installation method of the present invention: the difference from Embodiment 1 is that in the first step, the left connector of the bracket connector is assembled on the brush bracket from bottom to top from the upper side of the left brush.

[0026]Embodiment 3 of the brush installation method of the present invention: the difference from Embodiment 1 is that in the first step, the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com