A cutting method for braided electronic components

A technology of electronic components and cutting method, applied in the cutting field of tape electronic components, can solve the problems of uneven cutting length and low efficiency, and achieve the effect of realizing automation, high degree of automation and reducing error operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

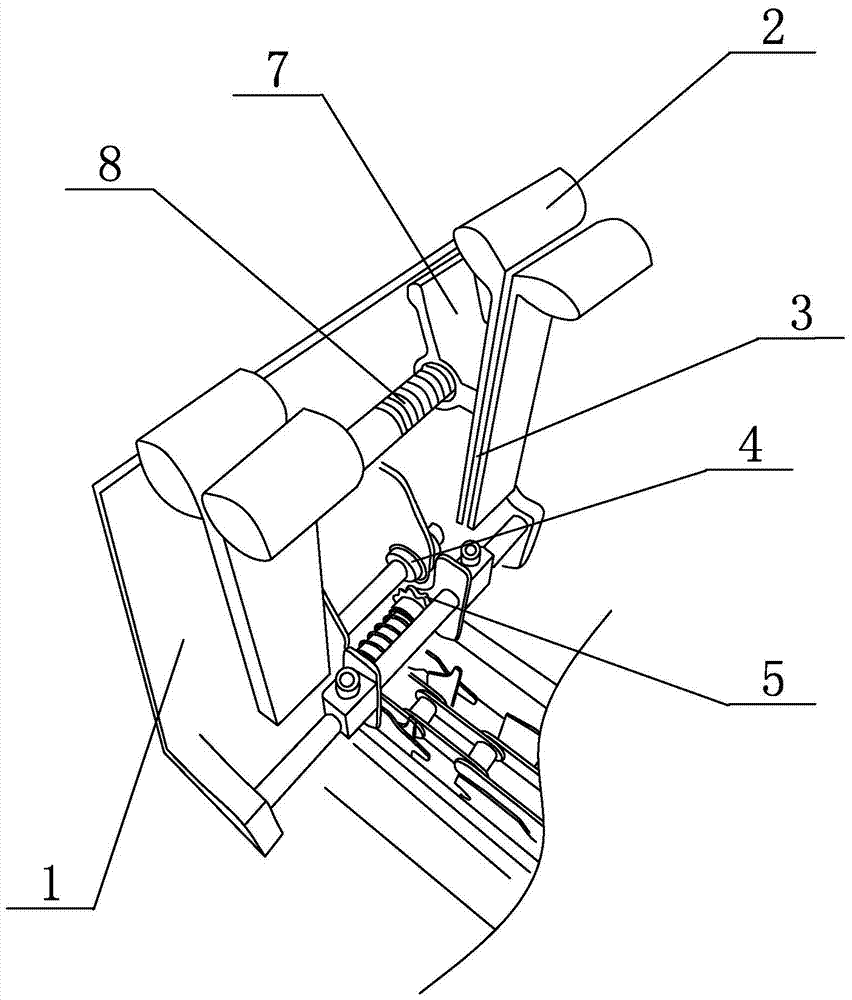

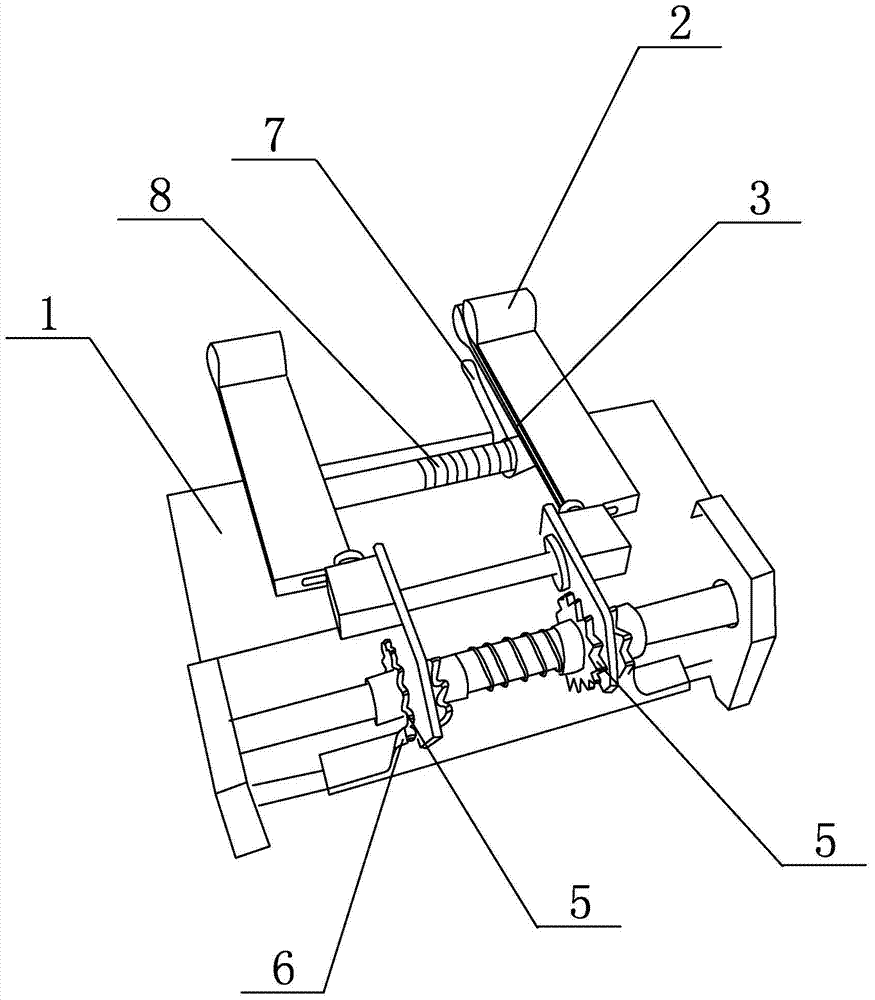

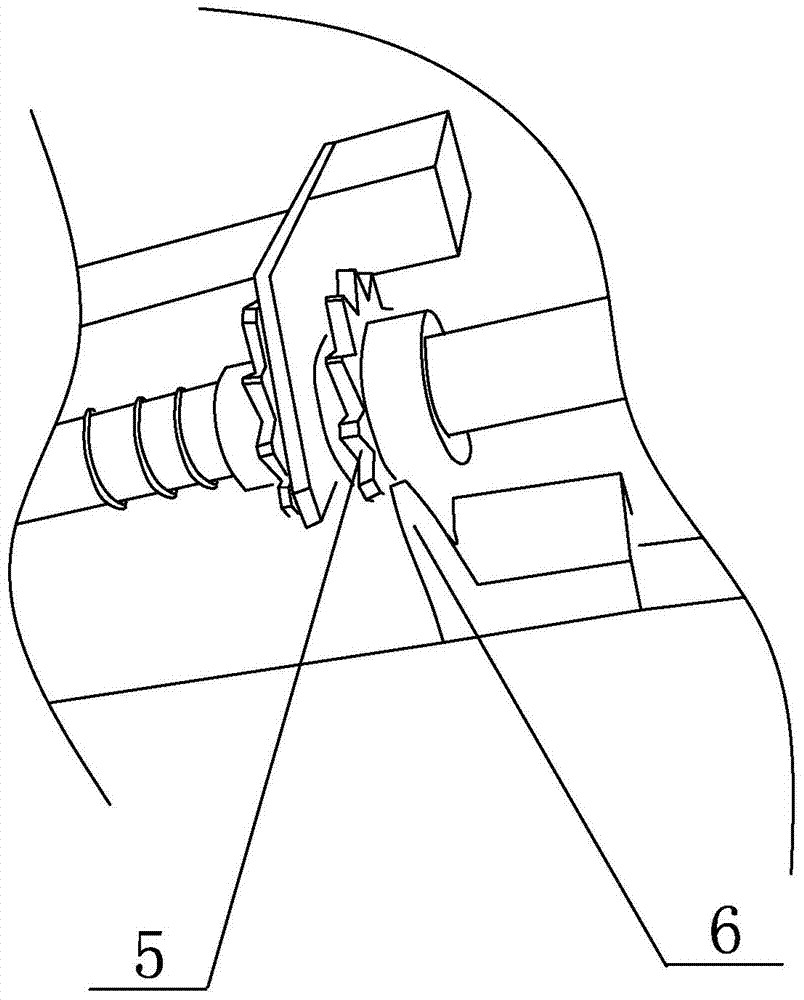

[0017] A cutting method for braided electronic components, comprising the following steps: ① unloading, putting the braided electronic components into the material inlet; ② adjusting, adjusting the electronic components at the front end so that both ends are stably positioned on the oppositely set transmission teeth 5, and the transmission tooth 5 drives it to rotate; ③ cutting, the transmission tooth 5 drives the braided electronic components to rotate, and sends it to the cutter 6 placed on the outside of the transmission tooth 5 for cutting, realizing electronic Components are separated from the braid; ④Transmission, the cut electronic components fall into the lower transmission track for output.

[0018] Such as figure 1 , figure 2 , image 3 As shown, in the cutting method of braided electronic components according to the present invention, the feed port includes a fixed seat 1 and two splints 2 symmetrically arranged on the fixed seat 1, and the inside of the splint 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com