Console assembly of crawler self-propelled rotovator and crawler self-propelled rotovator

A rotary cultivator and self-propelled technology, applied in the field of crawler self-propelled rotary cultivators, can solve the problems of inability to set up user-friendly facilities, inconvenient operation, many operating handles, etc., so as to increase the user-friendly facilities, reduce the quantity, The effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings, but this specific embodiment is only a preferred embodiment of the present invention, and it is easy for those skilled in the art to think of additional advantages and modifications. Therefore, the broad scope of the invention should not be limited to the specific details and typical embodiments described herein. Correspondingly, various modifications made without departing from the general spirit or scope of the concept of the present invention shall fall within the protection scope of the appended claims and their equivalents.

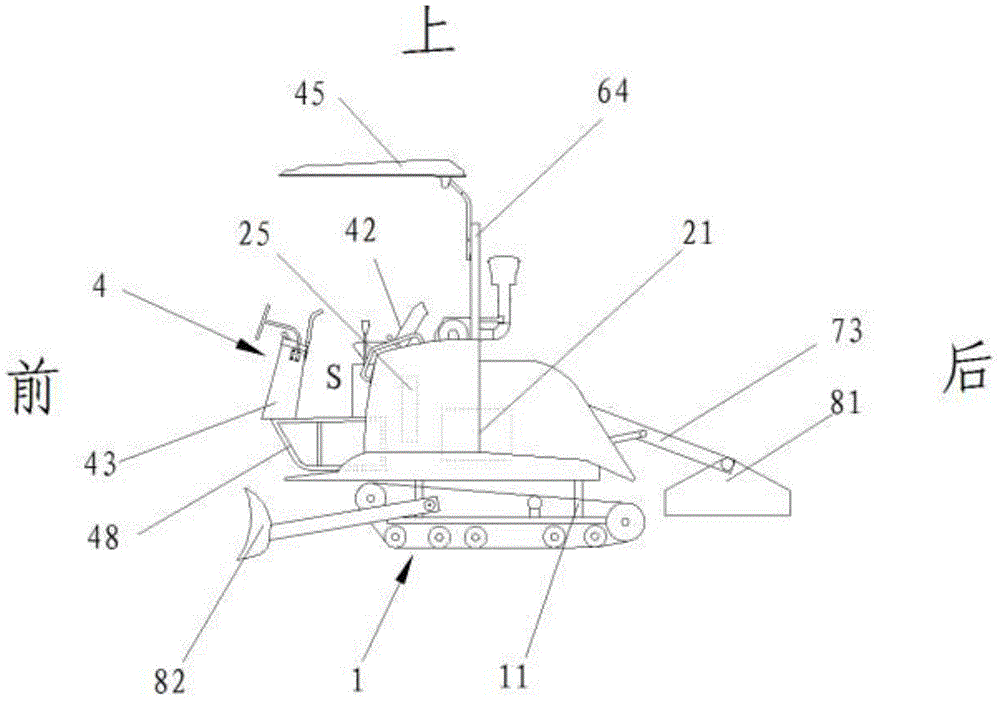

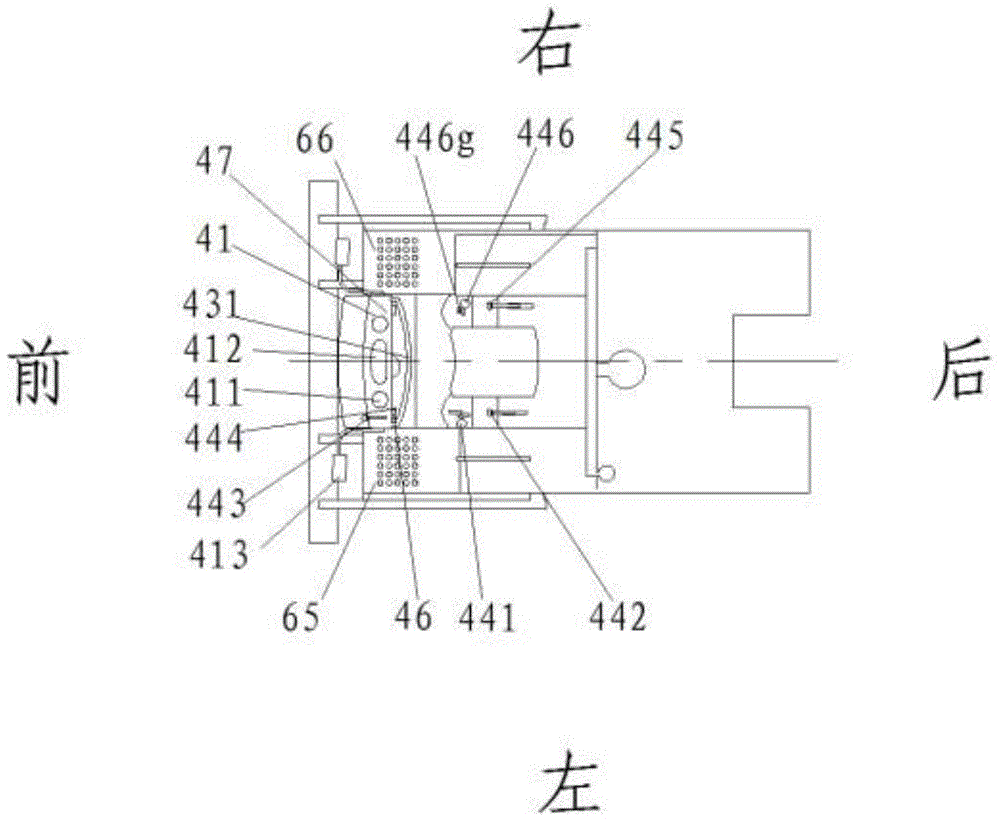

[0017] Such as figure 1 As shown, the console assembly of the crawler self-propelled rotary cultivator of the present invention includes an operating system 4, a driver's platform 43, and a seat 42; The top of the frame 11, the bottom of the awning 45, the front of the safety frame 64 and the rear upper part of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com