Roller brush with extrusion and uniform liquid discharging structure

A roller brush and roller technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of dripping, increasing the amount of decoration works, and soiling the ground.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

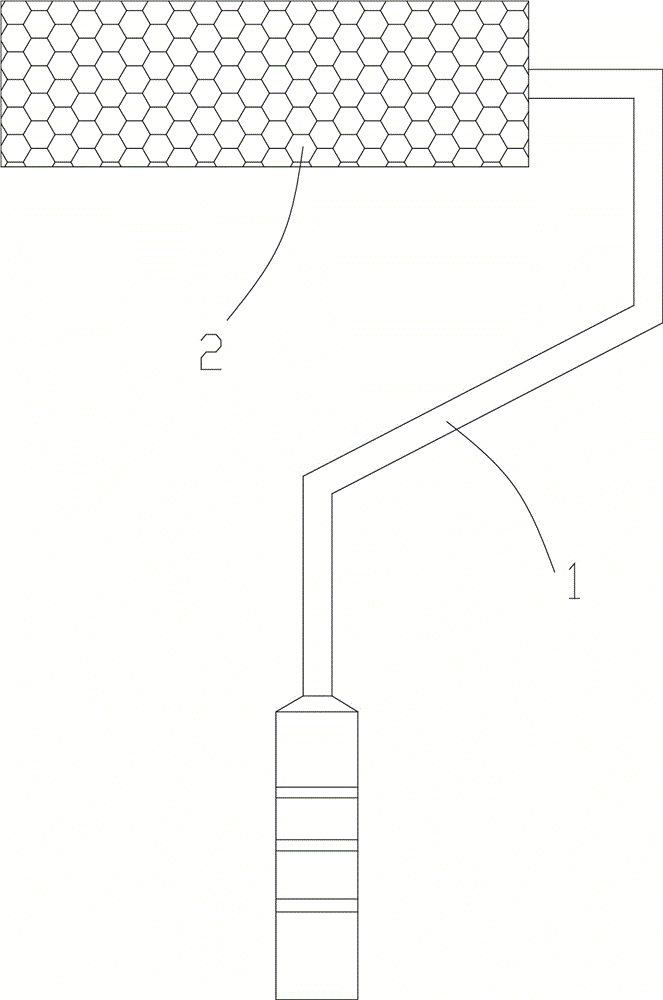

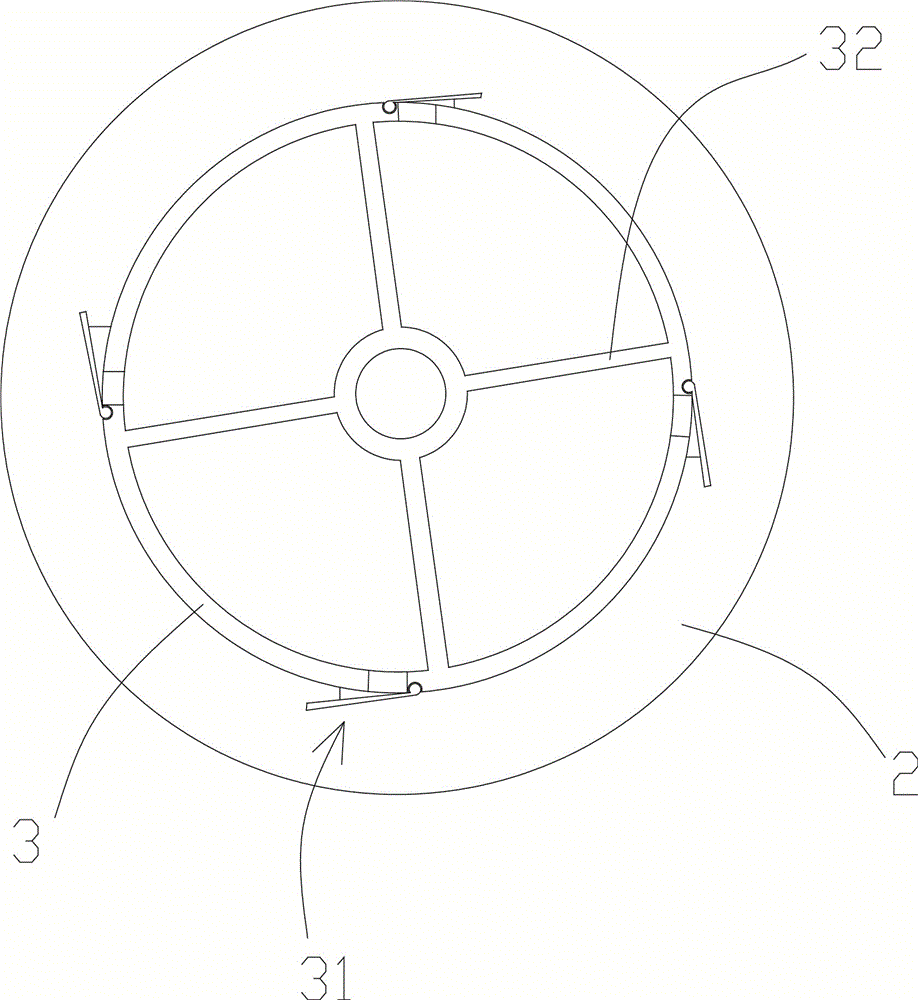

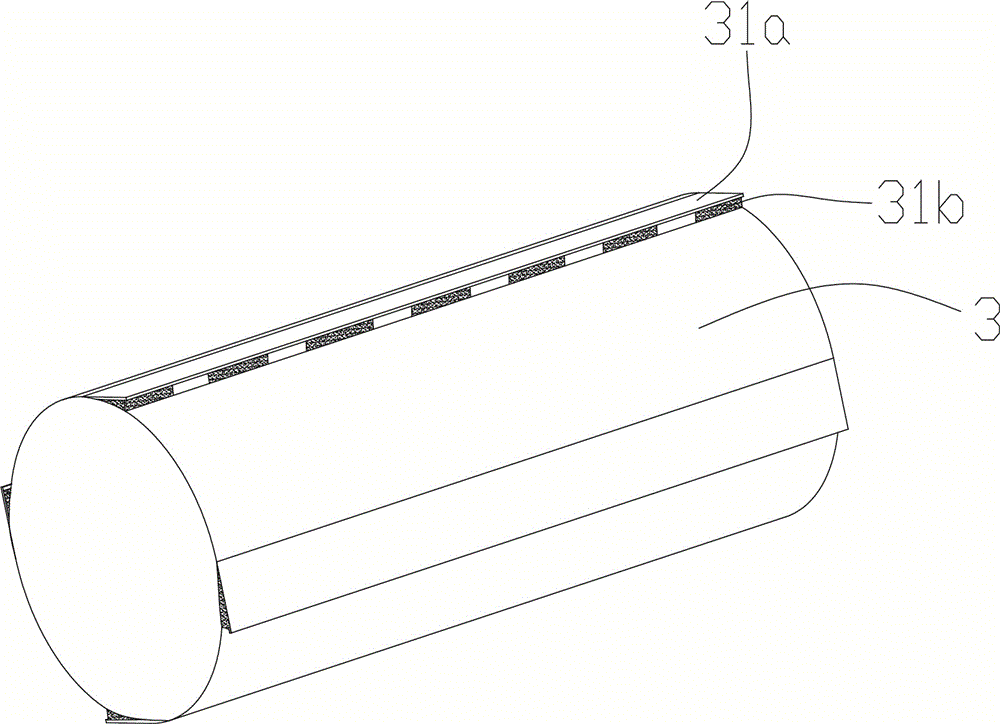

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Figure 1 to Figure 5 As shown, a roller brush with an evenly squeezed liquid outlet structure includes a roller that can be connected to a bracket 1. The roller includes a hollow roller body 3 and a sponge layer 2 covering it. The sponge layer 2 and the roller body are 3 sets Next, the technical measures taken include: the circumference of the drum body 3 is provided with at least four rows of liquid discharge holes arranged in equal arcs, and a one-way liquid discharge structure 31 is connected to the liquid discharge holes, and the one-way liquid discharge structure 31 includes a The plectrum 31a of closed structure, the plectrum 31a is connected to the drum body 3 on one side, and the other side is in clearance fit with the drum body 3.

[0020] When the roller brush is in rolling contact with the wall, part of the sponge layer close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com