Punching riveting connection device of torsion frame and punching riveting forming structure of its processed parts

A connecting device and frame technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve problems such as infirmity, high preparation cost, and difficulty in ensuring installation effect, and achieve reasonable and advanced structure, high degree of automation, and manufacturing good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

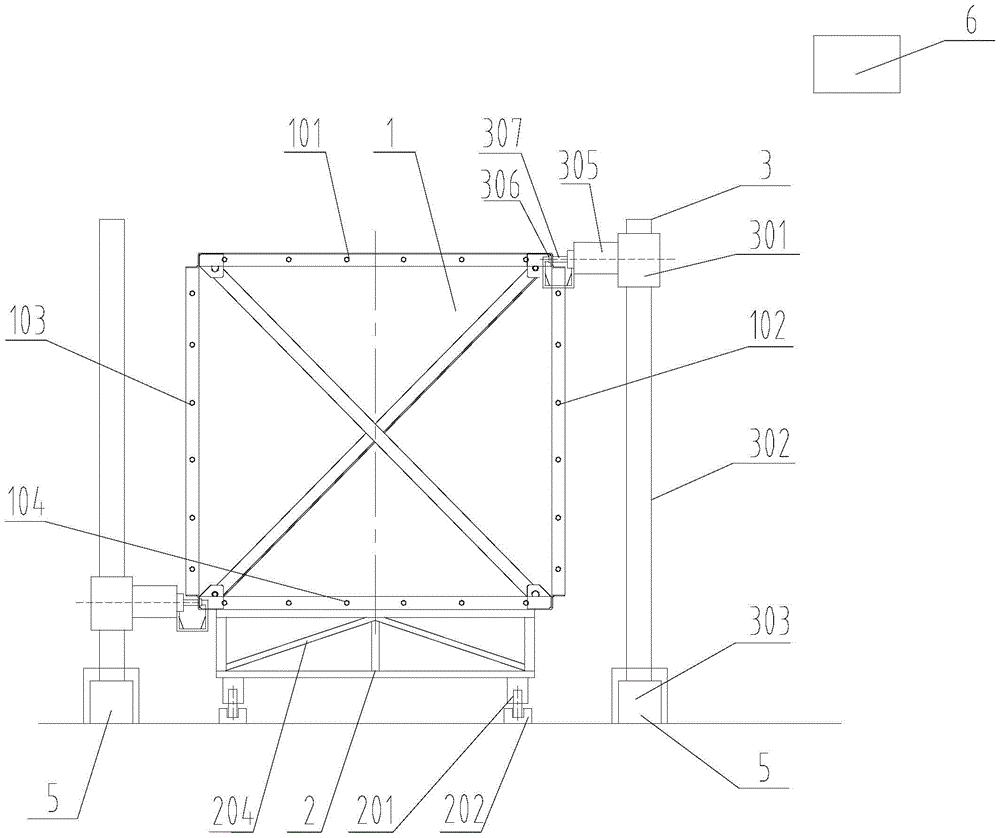

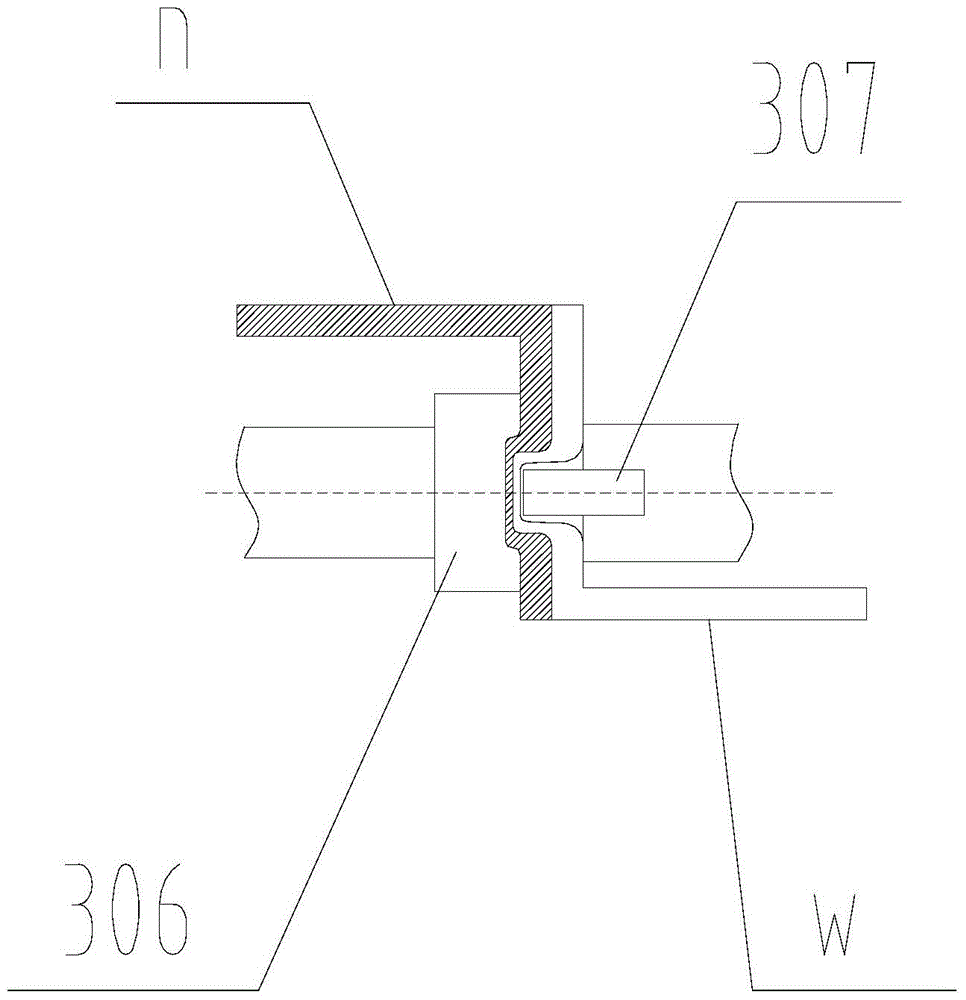

[0033] The second specific implementation mode, as attached figure 1 , 2 as shown,

[0034] A punching riveting connection device for a torsion frame of a trough solar collector, the torsion frame 1 includes a top torsion frame single piece 101, a right torsion frame single piece 102, a left torsion frame single piece 103 and a bottom torsion frame single piece 104 The four are arranged in a rectangular shape, and the four right-angle connection parts composed of four single-piece torsion frames are riveted and connected into one body through several riveting points arranged at intervals along their length directions. The punching riveting connection device ,include:

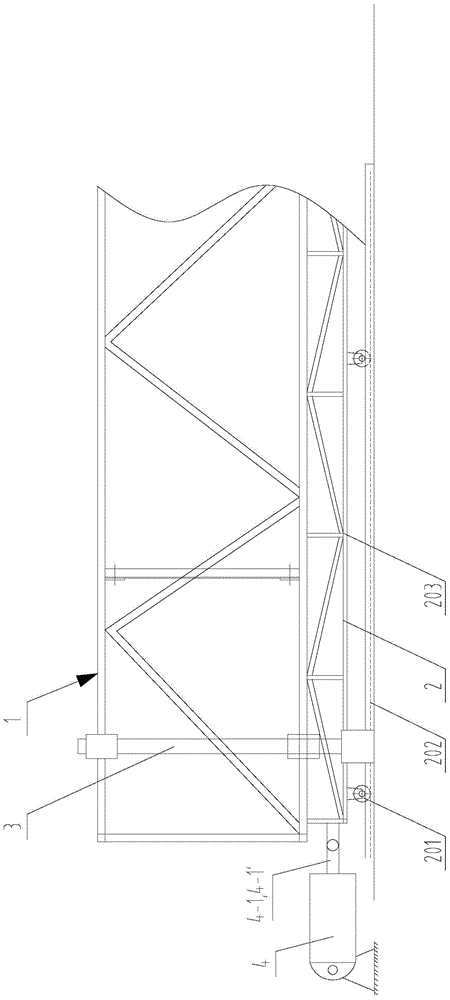

[0035]A transmission member 2; the transmission member 2 includes rollers 201, guide rails 202, and a support platform 204 whose width and length are adapted to the torsion frame 1; at least four rollers 201 are arranged on the bottom surface of the support platform 204 with spacing around, front and rear, An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com