Automatic pushing platform for woodworking

An automatic and woodworking technology, which is applied in the direction of wood processing equipment, manufacturing tools, sawing components, etc., can solve the problems of technical workers with low cultural quality, incompetence in work, and inability to meet production requirements, so as to reduce work-related injuries, improve safety, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

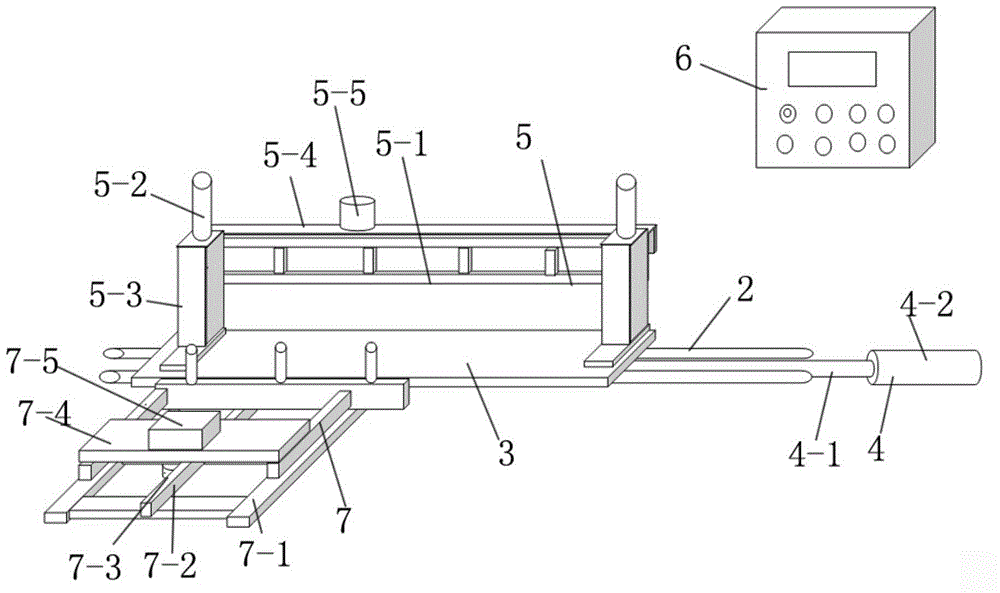

[0024] Such as figure 1 As shown, the present invention is an automatic woodworking push table which includes a frame 1, a guide rail-2 arranged on the frame 1, and a push table 3 slidingly matched with the guide rail-2, connected to drive the push table to slide along the guide rail-1 Device 4, the wood positioning mechanism 5 arranged on the push platform, and the main controller 6 connected to the control power unit and the wood positioning mechanism, the power unit 4 includes a pressure cylinder one 4-1 arranged on the frame, and a pressure cylinder one 4 The pressure rod 4-2 of -1 is connected to one end of the push platform, and the pressure rod is used as the power to replace the manual operation. Wherein, the pressure cylinder 4-1 can be in the form of an air cylinder or a hydraulic cylinder, and what this embodiment uses is an air cylinder .

[0025] The outside of push platform 3 is provided with timber cross-feeding mechanism 7, and timber cross-feed mechanism comp...

Embodiment 2

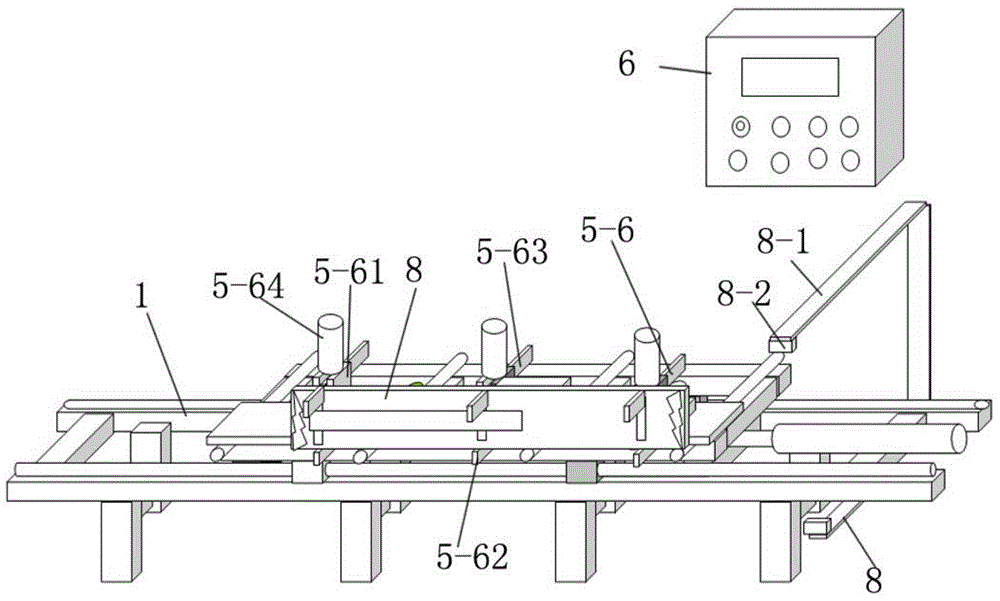

[0028] Such as figure 2 As shown, in the present embodiment, the push platform is a log push platform. One side of the log push platform is provided with a positioning baffle 8. Timber positioning mechanism 5 comprises at least three groups of manipulators 5-6 arranged along the direction of the guide rail on the log push platform. Between the fixed clip 5-62 and the movable clip 5-63 matched with the fixed clip, one or both ends of the fixed clip and the movable clip extend to the outside of the positioning splint on both sides, and the movable clip is connected with a drive The lifting pressure cylinder 3 5-64 forms a clamping structure corresponding to logs.

[0029] An infrared positioning device 8 for identifying the diameter of the log is arranged outside the log pushing platform, and the signal output end of the infrared positioning device is connected to the main controller 6 . The infrared positioning device 8 includes a C-shaped bracket 8-1 perpendicular to the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com