Pre-stressed concrete solid square pile production device

一种预应力、混凝土的技术,应用在陶瓷成型机、制造工具、模具等方向,能够解决管桩脆断桩基础水平承载力、砂石资源不能高效利用质量、钢材使用量大等问题,达到安全性提高、结构简单、确保产品质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The accompanying drawings disclose non-limiting specific embodiments of the present invention, which are further described as follows in conjunction with the accompanying drawings.

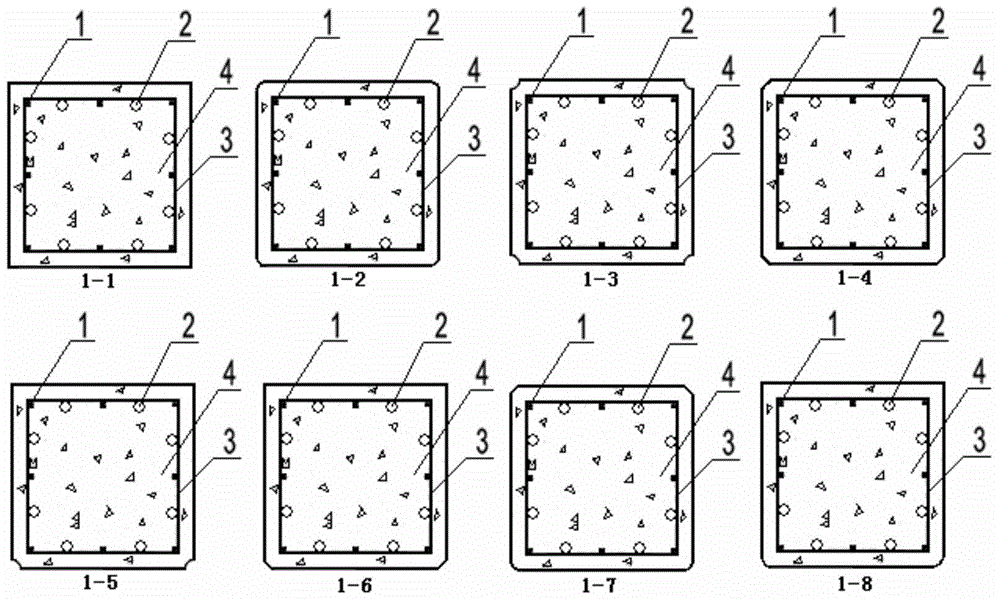

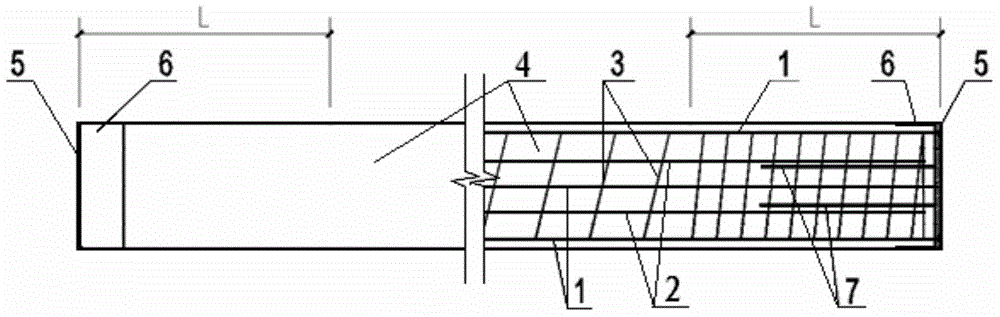

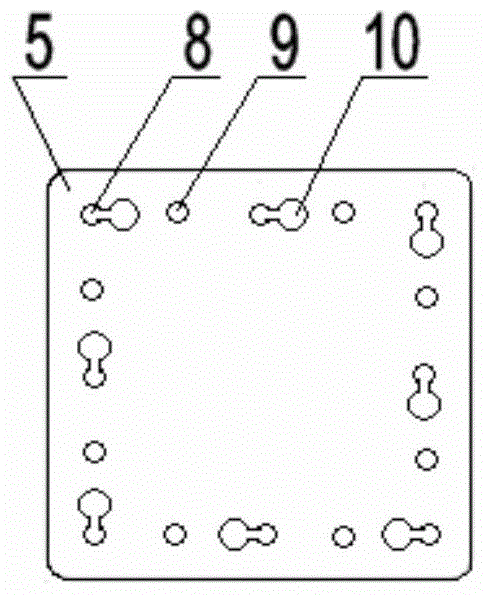

[0062] see figure 2 , the anti-seismic type prefabricated concrete solid square pile of the present invention comprises main reinforcement, stirrup 3, anchorage reinforcement 7, pile cap and concrete 4, and the main body of described pile body cross section is square, and main reinforcement is by prestressed main reinforcement 1 and common main reinforcement 2 successively Arrangement and combination, the main reinforcement runs through the pile body along the longitudinal axis of the pile body, the outer edge of the main reinforcement is the stirrup 3, and the stirrup 3 is a spiral square; the two ends of the pile body are pile caps, and the pile cap is composed of an end plate 5 and a skirt 6; The main reinforcement and the stirrup are connected by welding or binding to form a reinforcem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap