Self-enclosed packer

A self-sealing and packer technology, which is applied to floating buildings and other directions, can solve the problems of packer damage and failure, and achieve the effects of steel saving, simple installation process and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

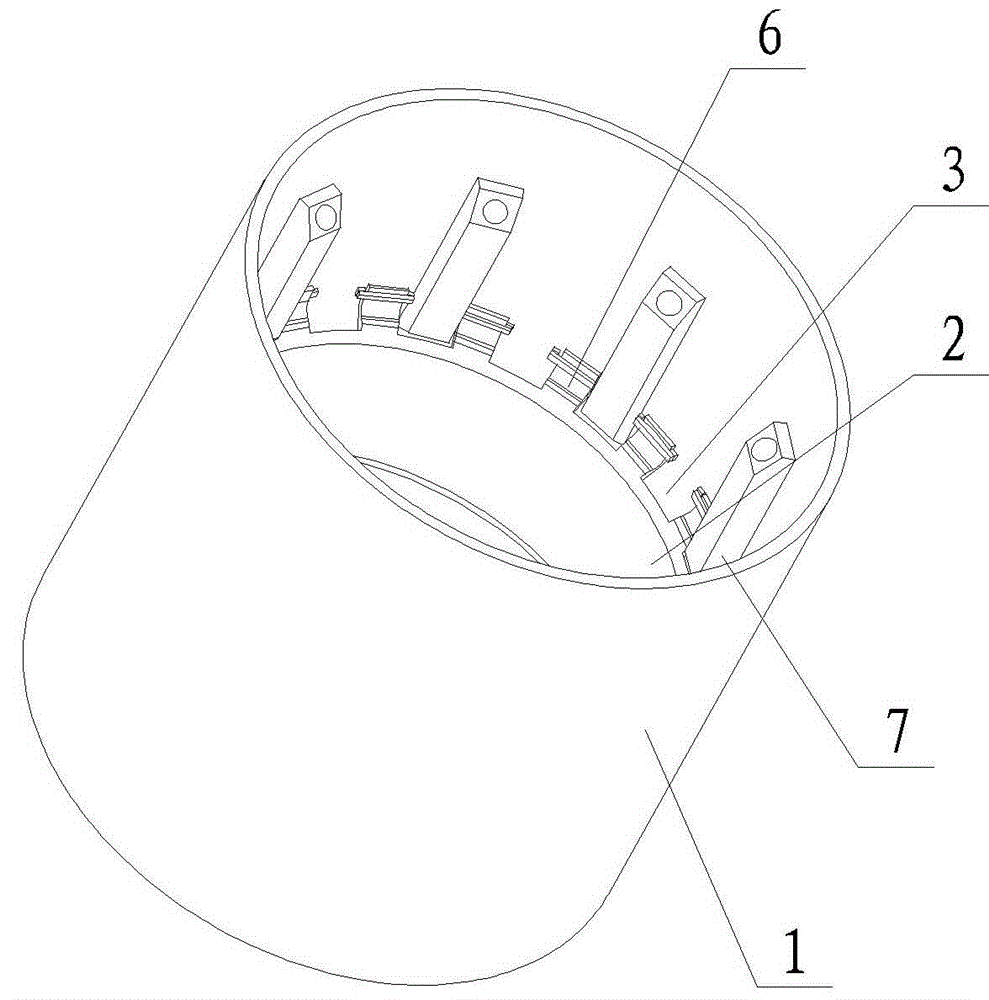

[0024] Embodiment one: see attached figure 1 , a self-sealing packer, located between the sleeve 1 and the pile 18, its key lies in: it includes a rubber sleeve 2 coaxial with the sleeve 1 and arranged at the inner bottom of the sleeve 2, and the bottom of the rubber sleeve 2 is fixed by a bottom fixing device It is sealingly connected with the sleeve 1 and forms a grout accommodating cavity with the gap between the rubber sleeve 2 and the sleeve 1 , and the top is connected with the sleeve 1 by means of a top fixing device and is provided with a grouting port 3 .

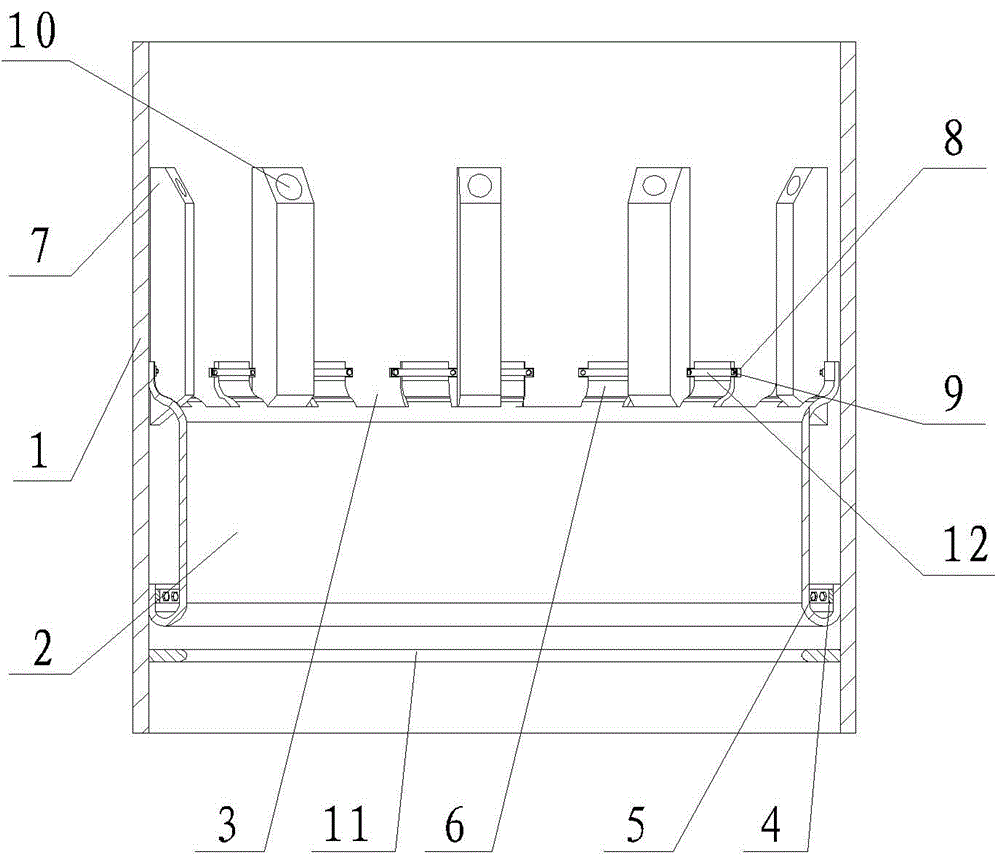

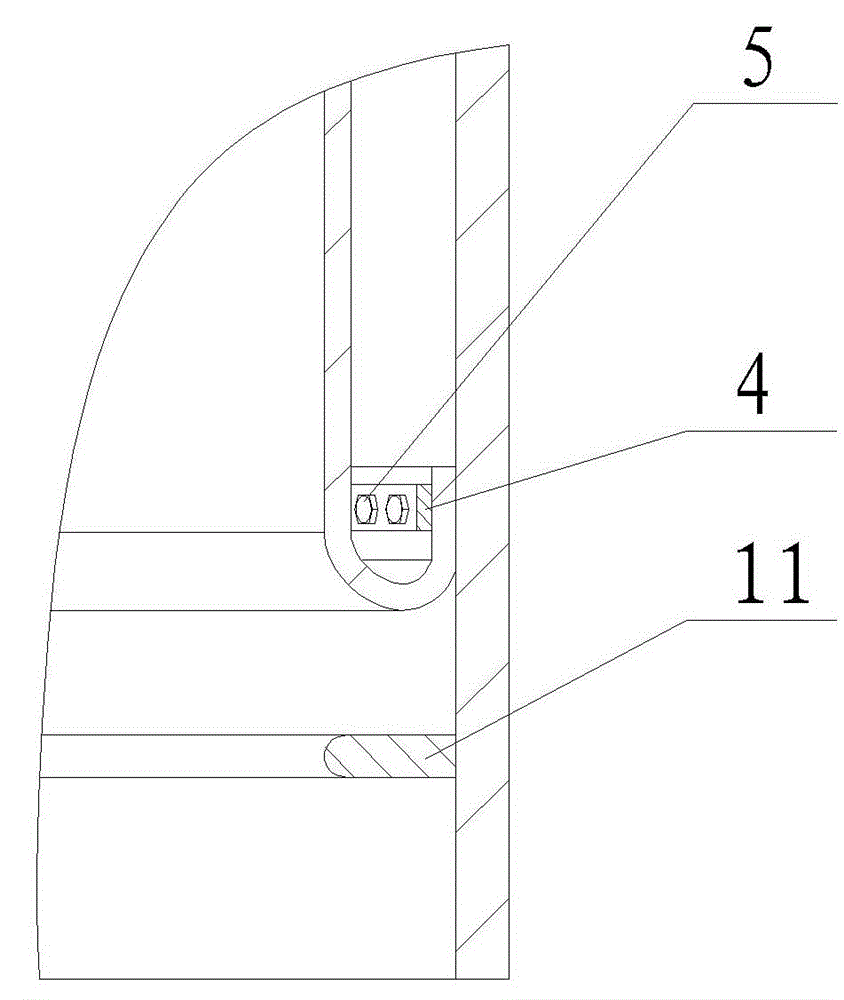

[0025] See attached figure 2 with image 3 , the bottom of the rubber sleeve 2 is bent towards the sleeve 1, and the bent part forms a sealed and fixed structure with the sleeve 1 by means of a bottom fixing device. The bent portion of the rubber sleeve 2 forms a gap between the rubber sleeve 2 and the sleeve 1 , thereby forming a cement slurry accommodating cavity.

[0026] The inner diameter of the middle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com