Conveying buffer table

A buffer table and conveyor belt technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of bottle blocking conveyor belt, limited radius of turntable, limited bottle capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

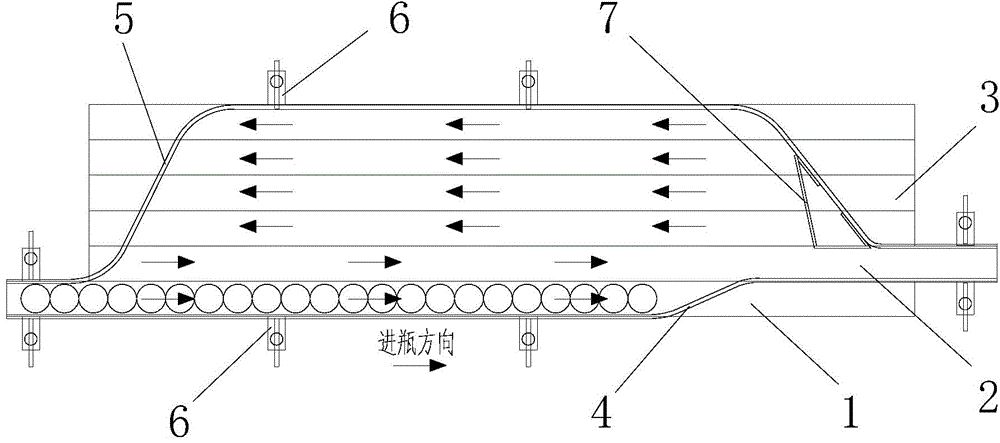

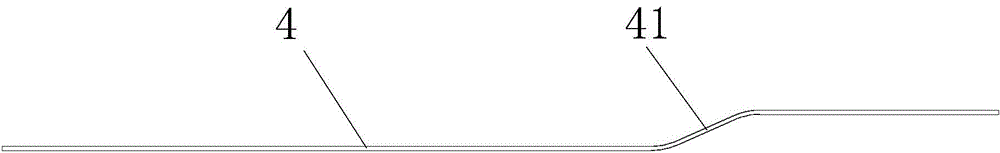

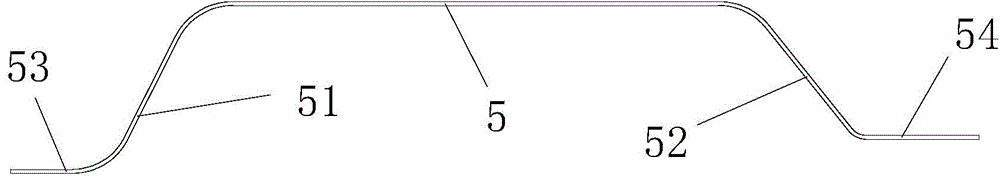

[0025] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0026] Such as Figure 1 to Figure 8 As shown, a conveying buffer table includes a frame, and at least 2 forward conveyor belts are arranged side by side on the frame, and each forward conveyor belt has a forward feed belt 1 positioned outside the frame and a The positive discharge belt 2 on the inner side is provided with a forward guardrail 4 above the forward feed belt 1 and the forward discharge belt 2, and the front end of the forward guardrail 4 is positioned above the outer side of the forward feed belt 1. The rear end of the guardrail 4 is positioned above the outer side of the forward discharge belt 2, and the forward guardrail 4 is formed with a guide slope for guiding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com