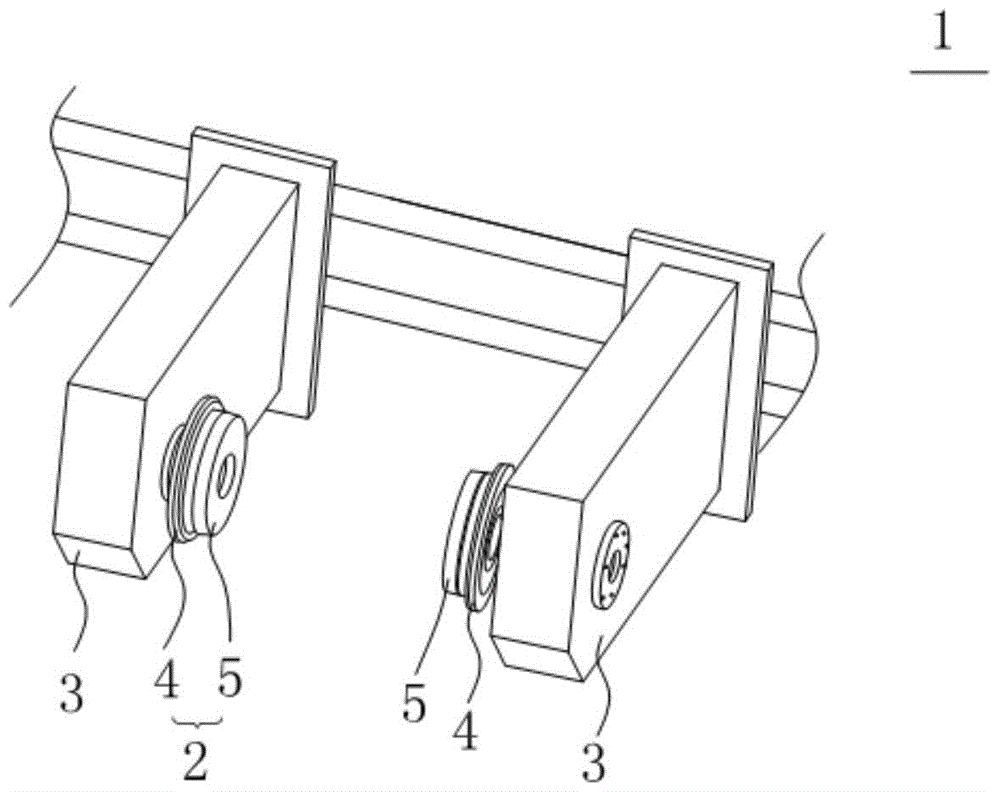

Clamping device and unwinding device

A clamping device and roll unwinding technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of inconvenient adjustment and non-adjustable clamping tension of chucks, etc., so as to save space and reduce The effect of reducing the risk of work-related injury and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

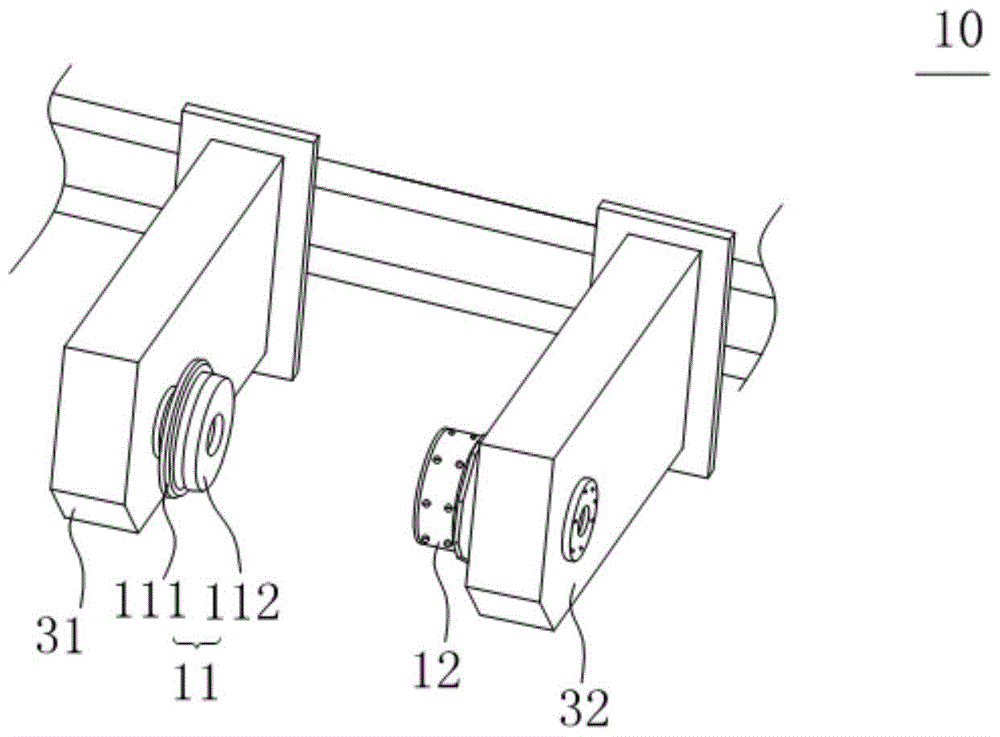

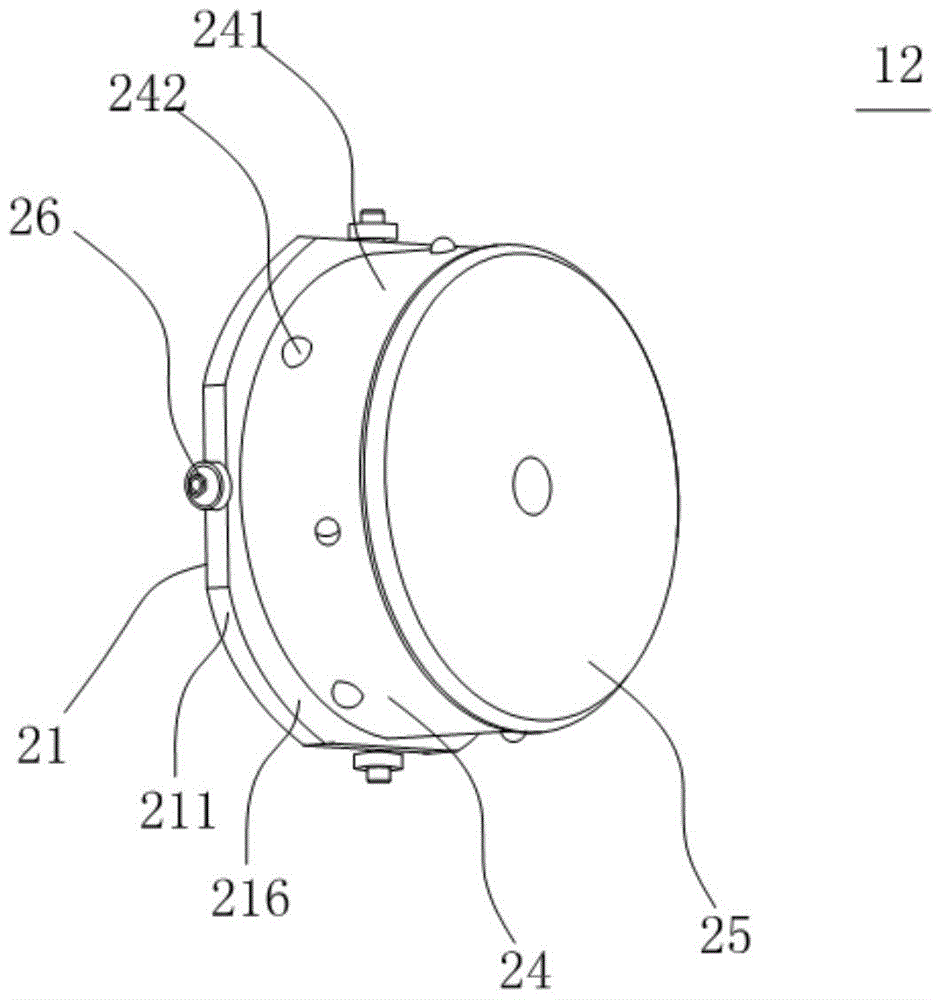

[0021] See figure 2 , figure 2 Shown is a schematic diagram of a winding and unwinding device according to the present invention. The present invention provides a winding and unwinding device 10. The winding and unwinding device 10 includes a clamping device and a core. The clamping device is used to clamp the core of the coil. The clamping device includes a first chuck 11 and a second chuck 12 oppositely arranged, and the first chuck 11 is fixed on the first bracket 31, and the second chuck 12 is fixed on the second bracket 32. The winding core is used for winding the coil, and two ends of the winding core are respectively sleeved on the first chuck 11 and the second chuck 12. The above-mentioned roll material is, for example, a film roll, and the film is, for example, a polarizing film or other optical film. When the present invention is not limited to this, for example, the above-mentioned film may also be other plastic films, such as battery film, cling film, packaging fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com