Patents

Literature

46results about How to "Reduce the risk of work-related injuries" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

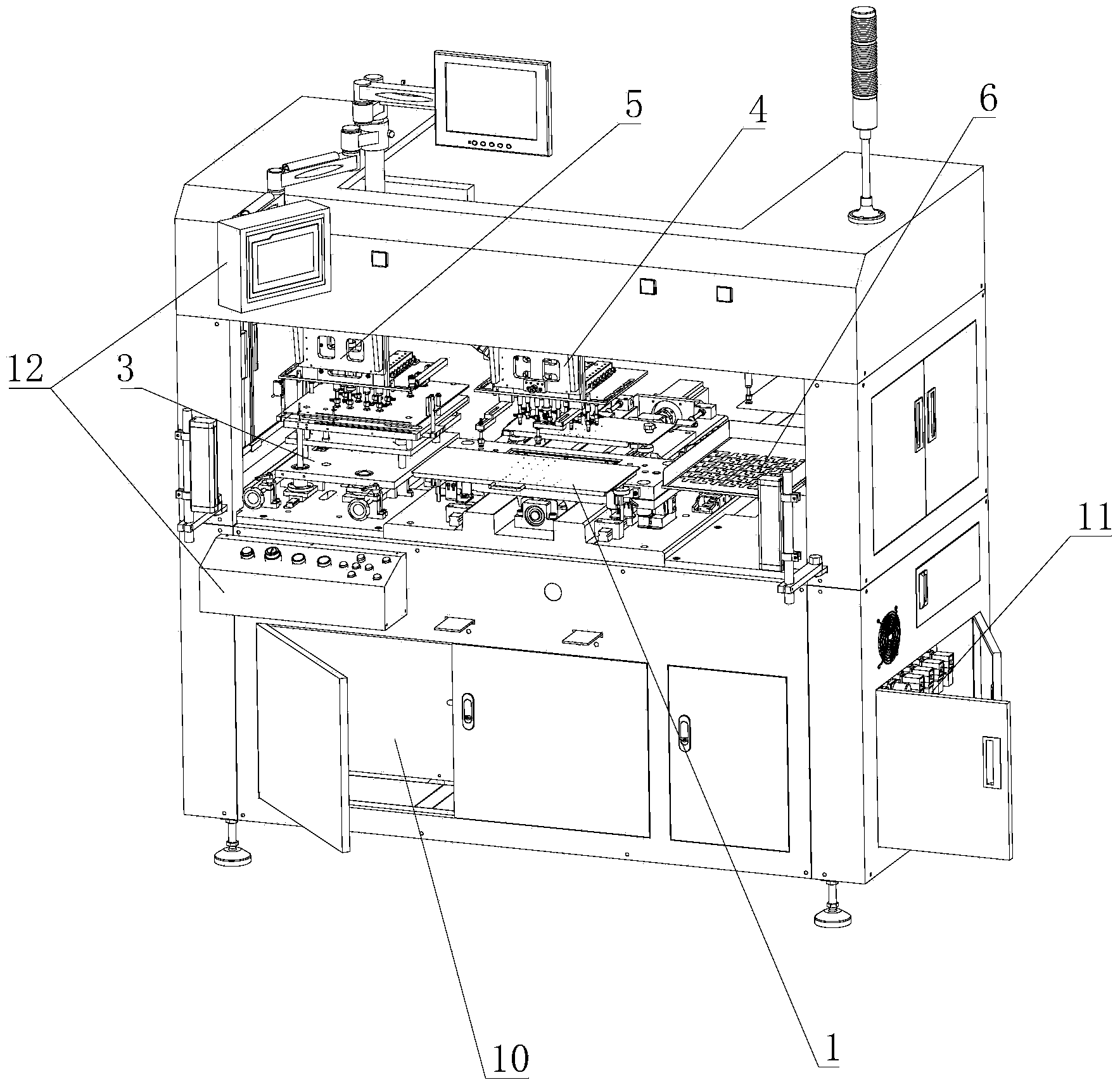

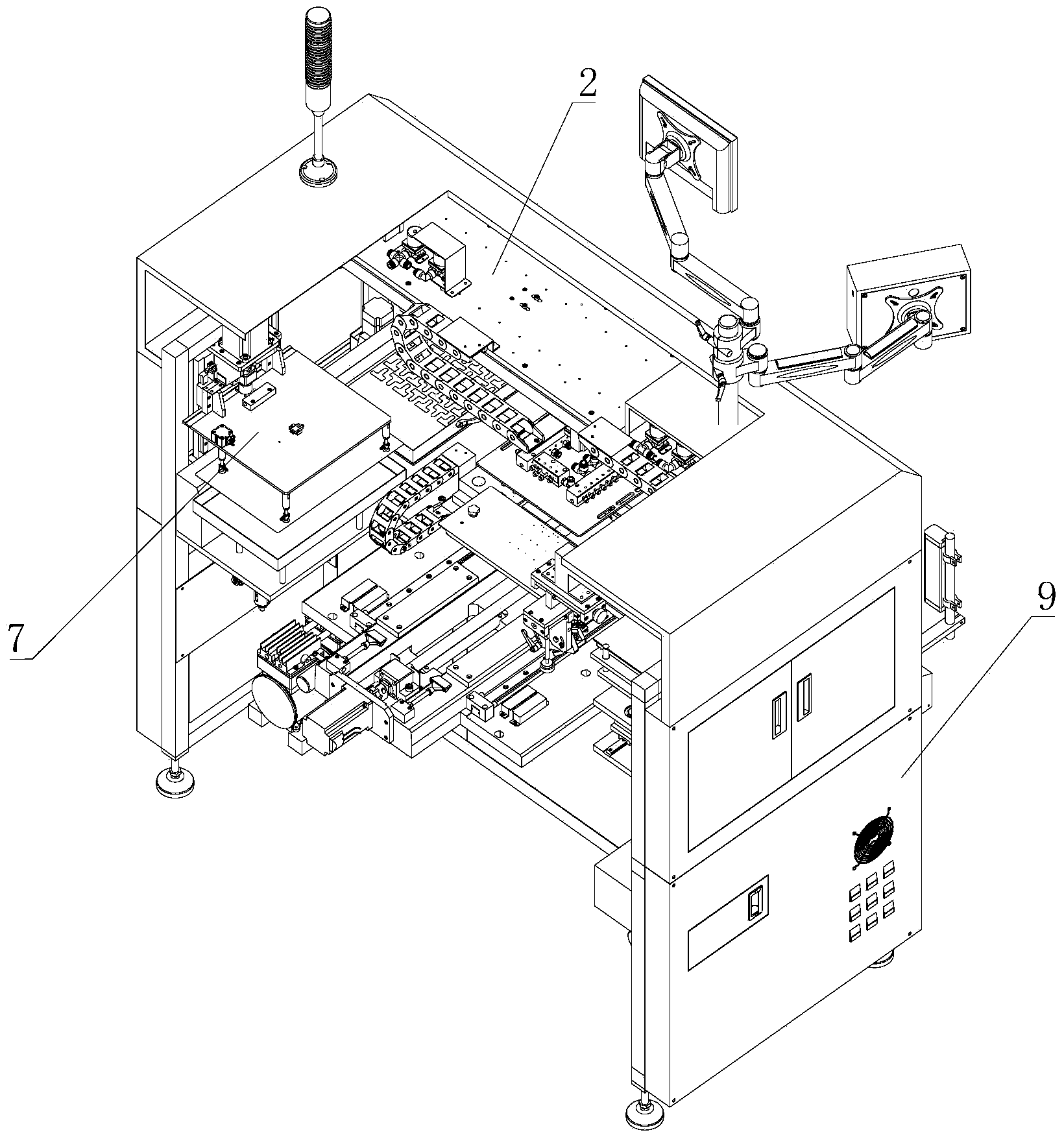

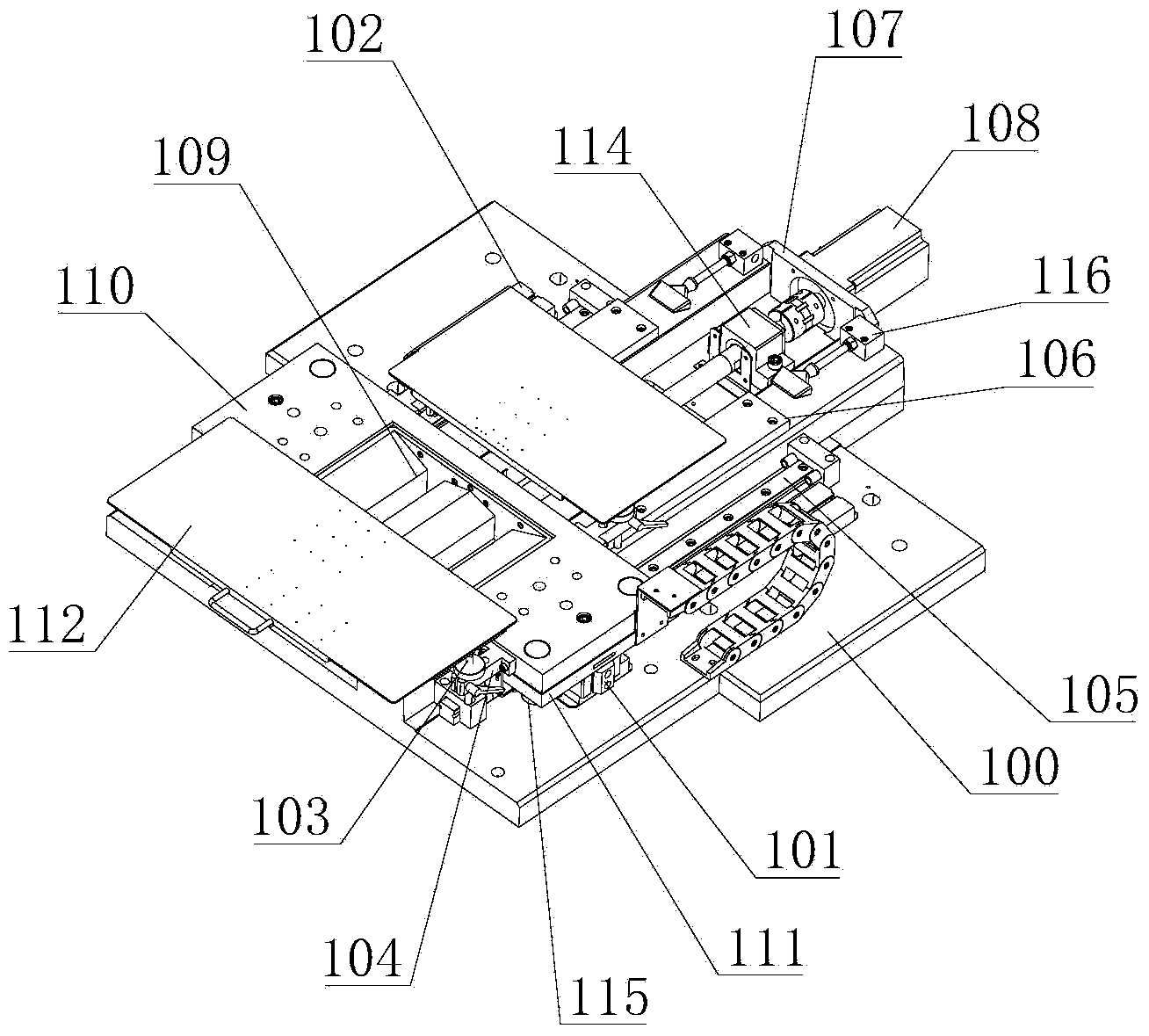

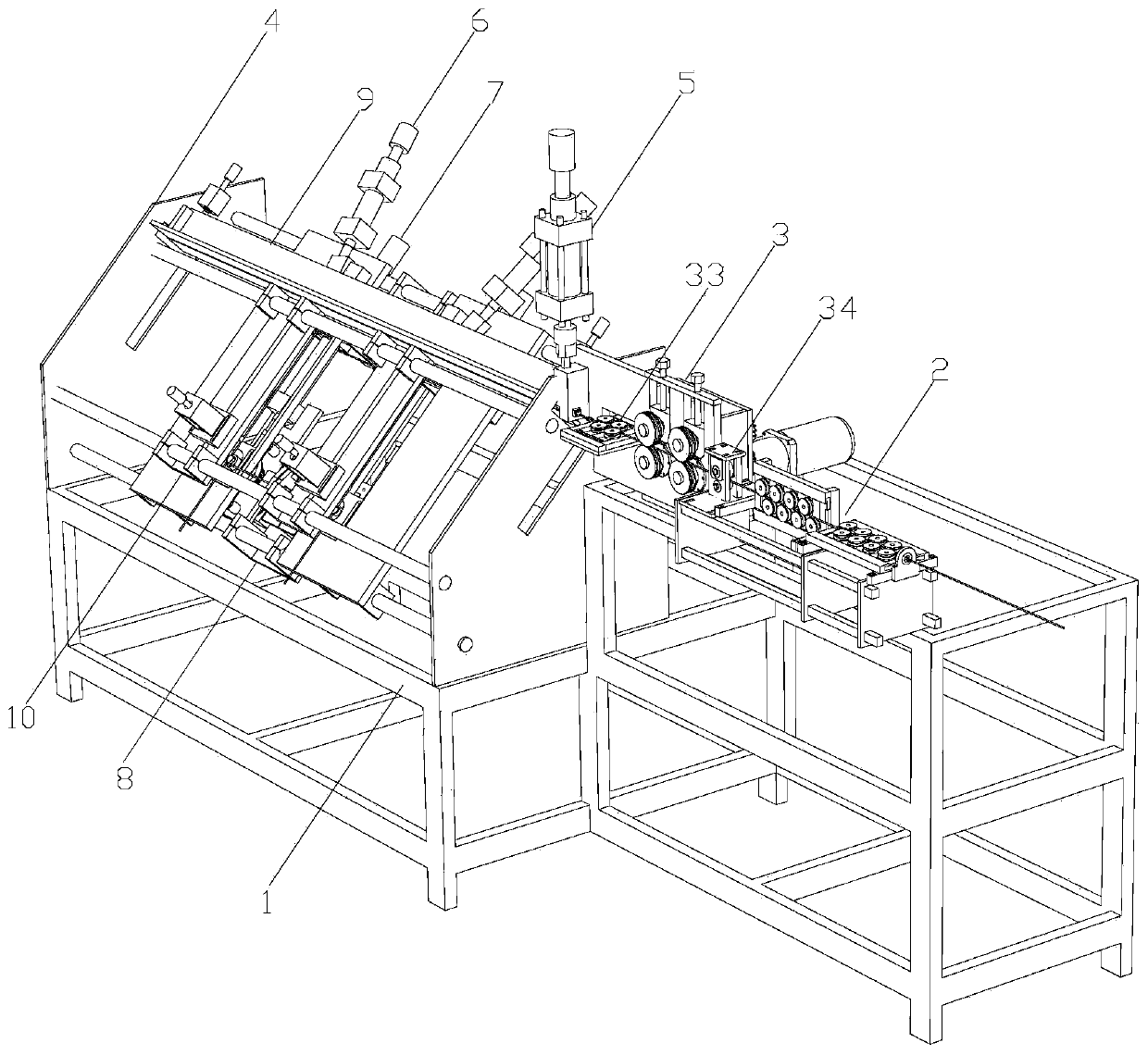

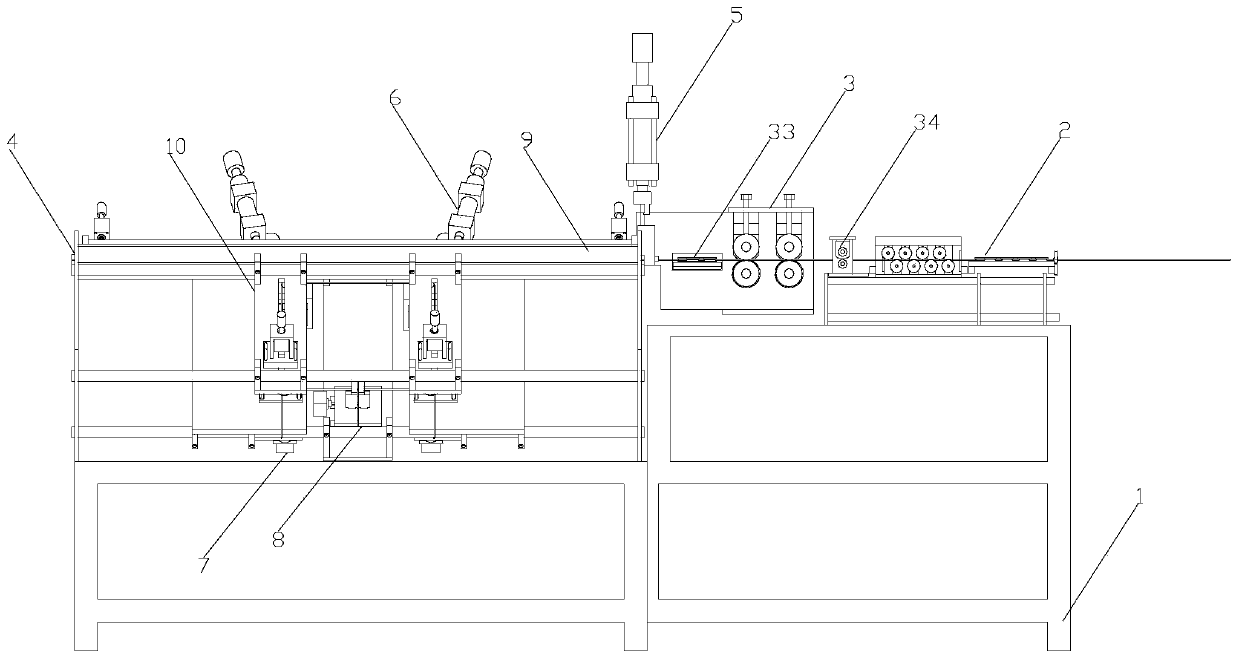

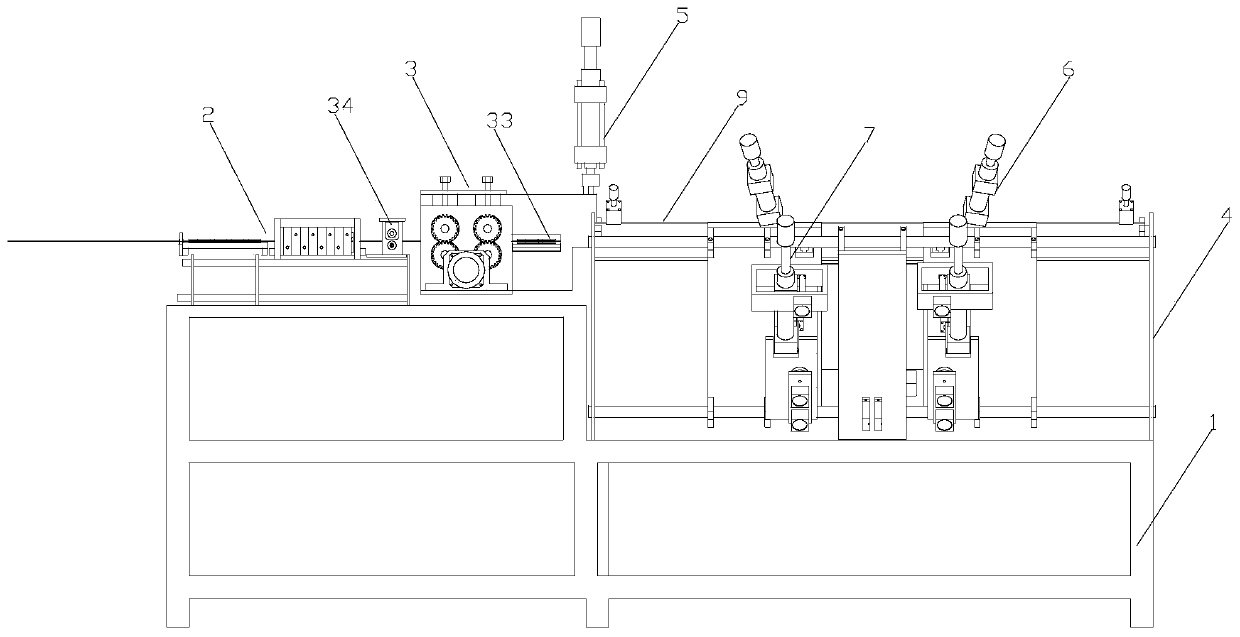

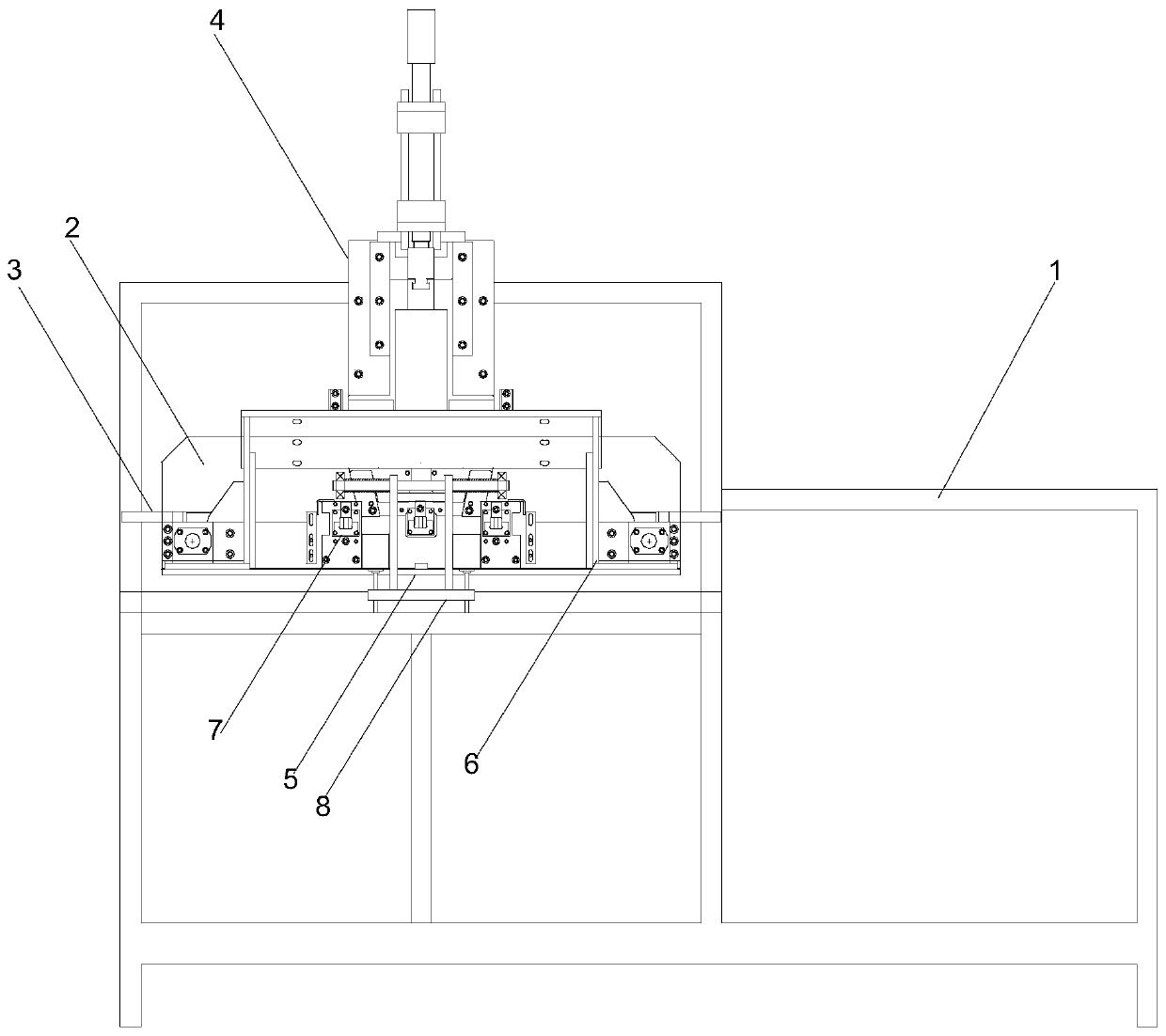

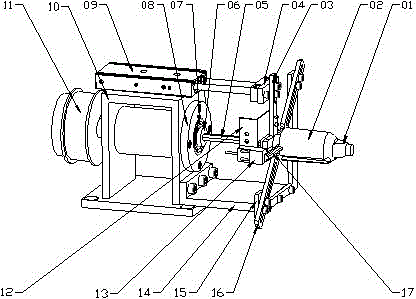

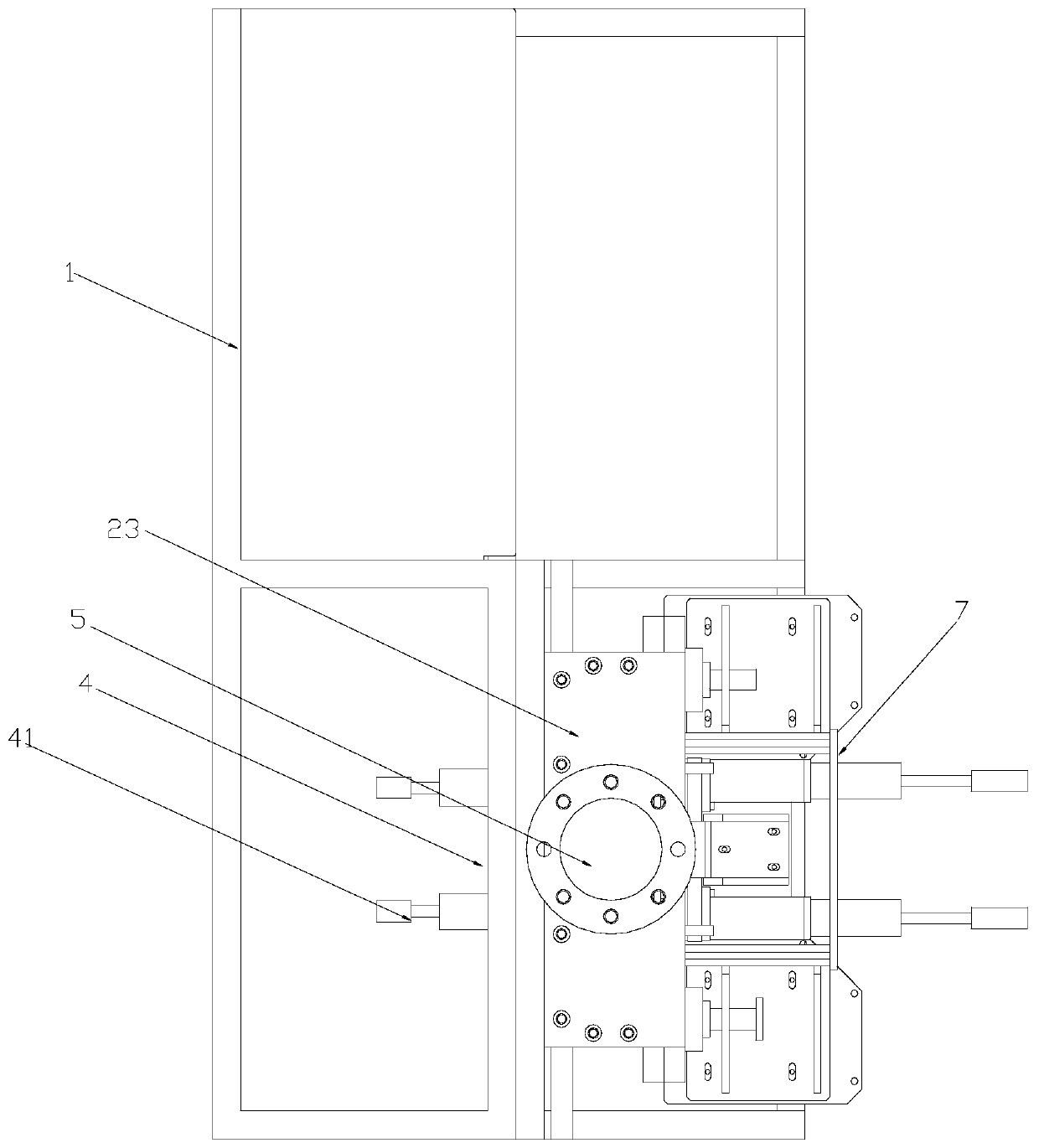

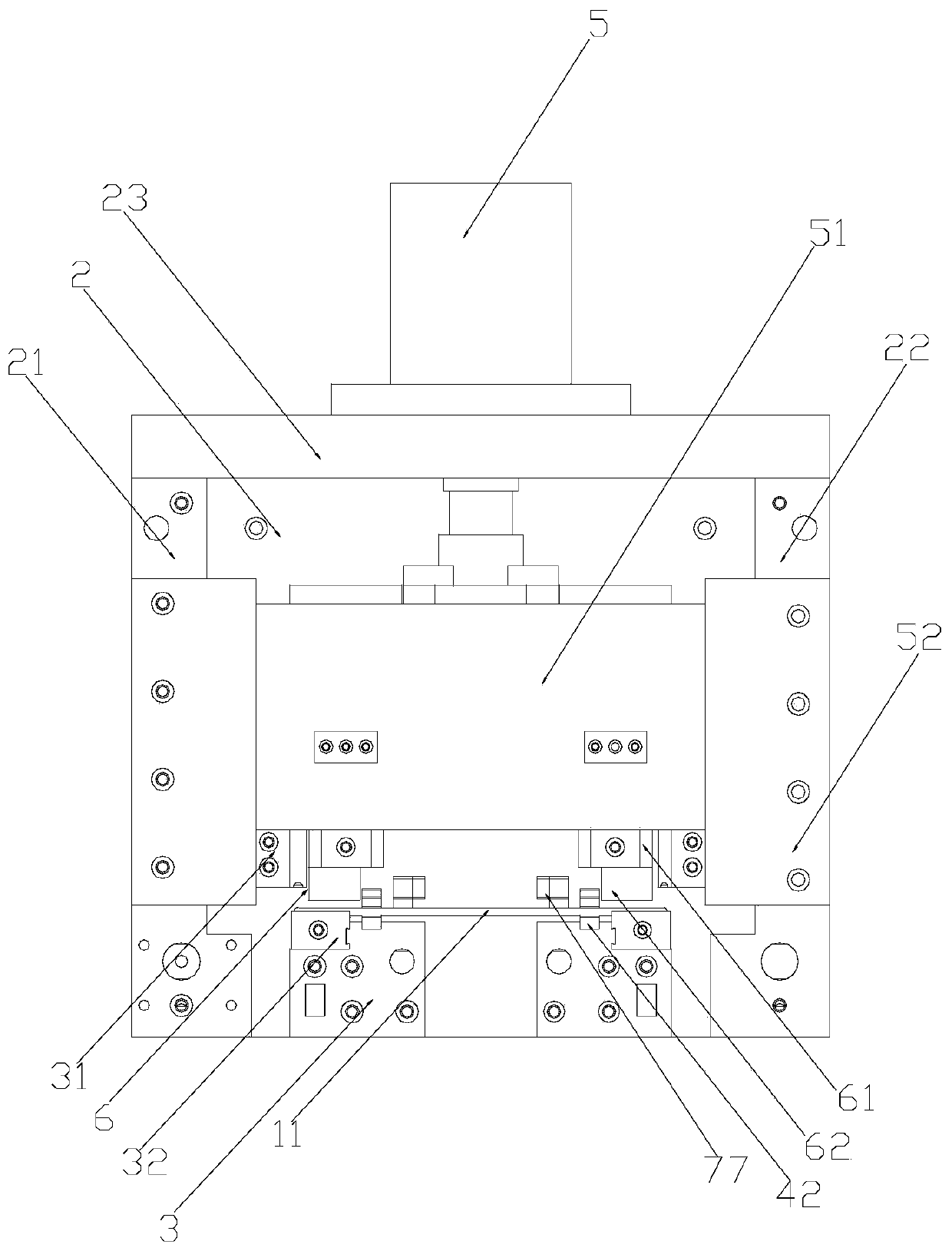

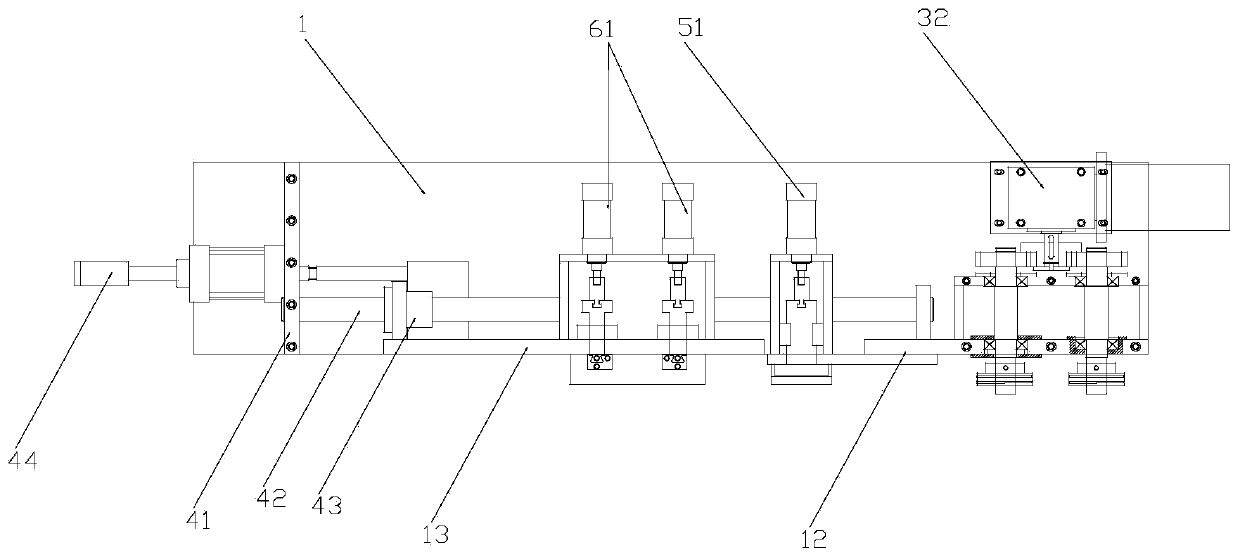

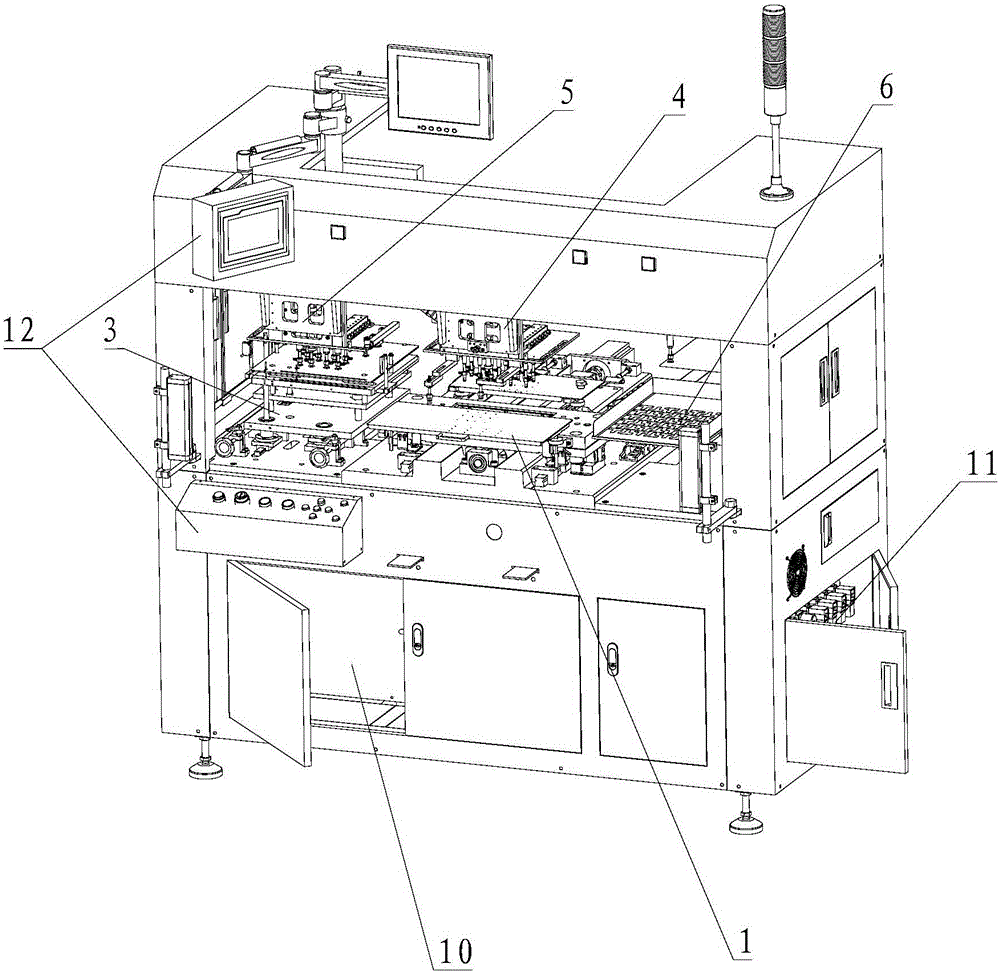

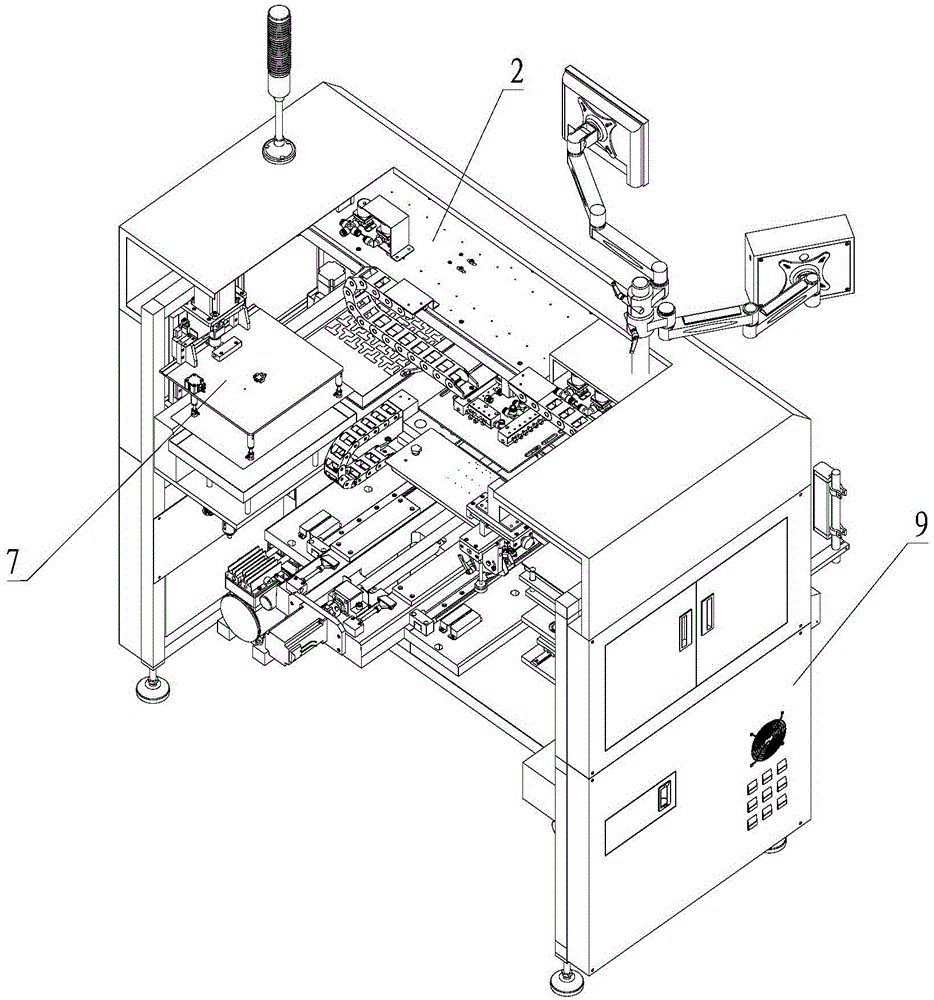

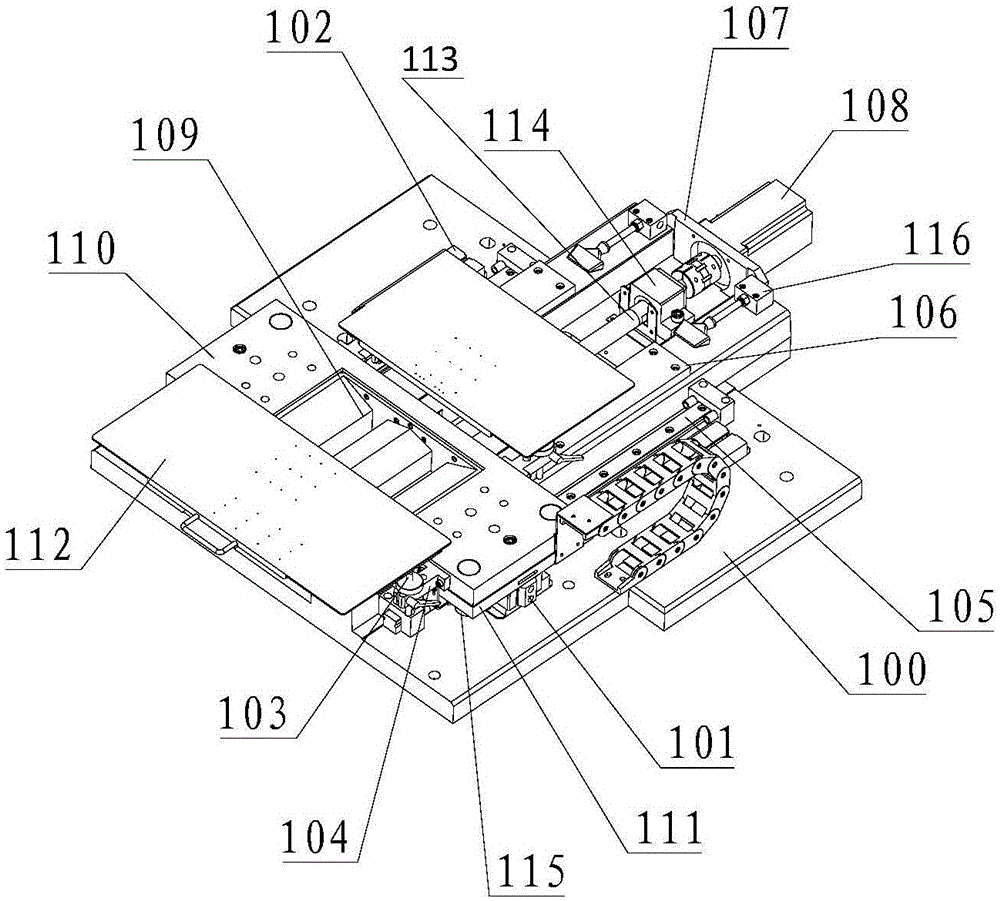

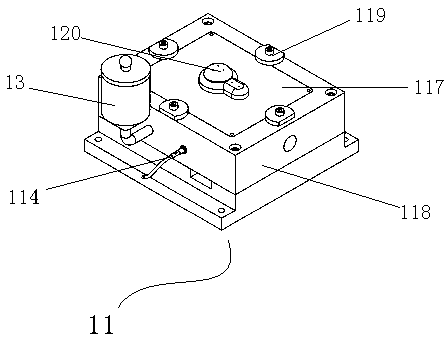

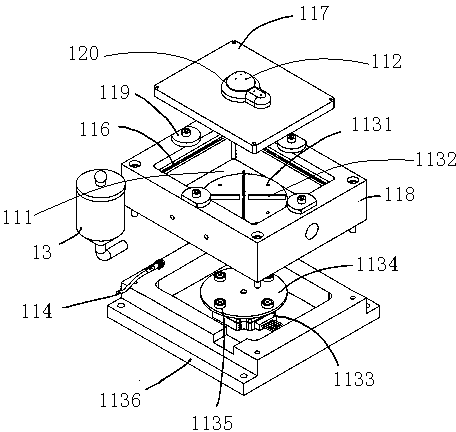

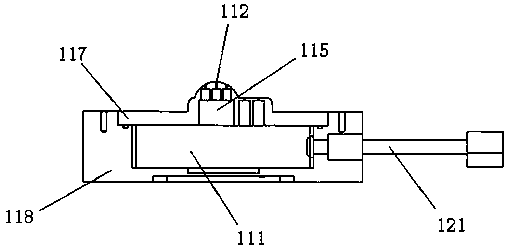

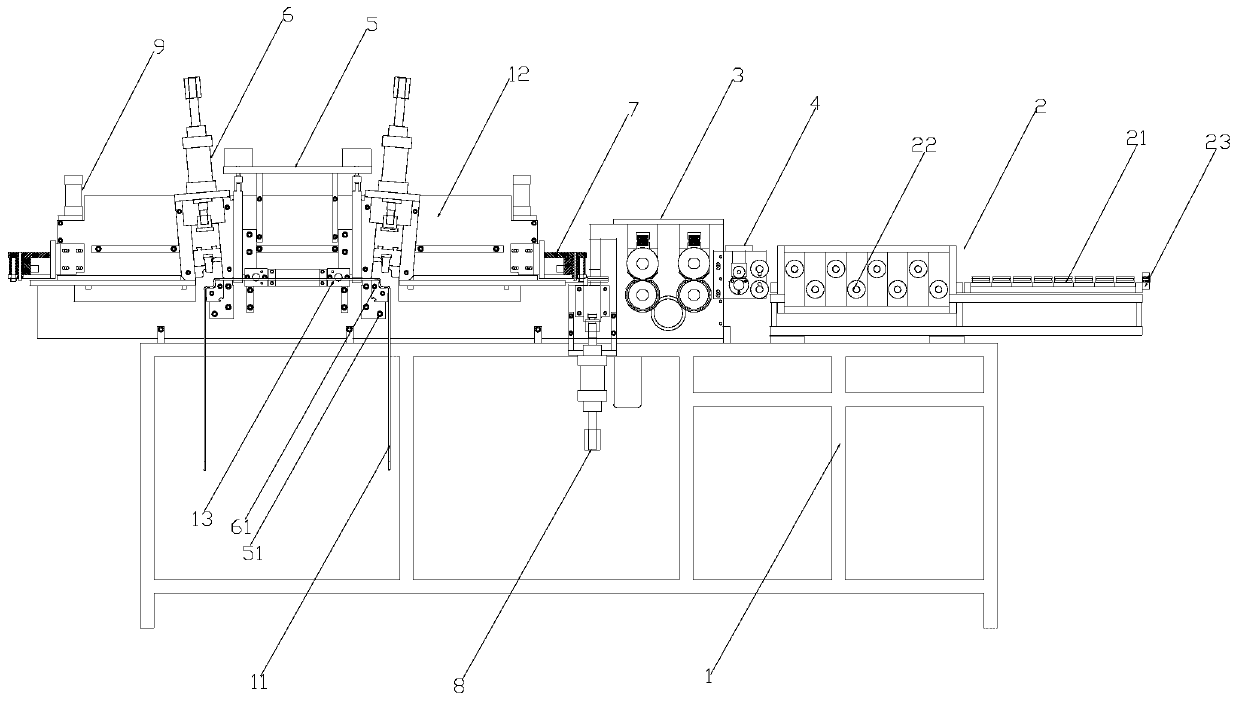

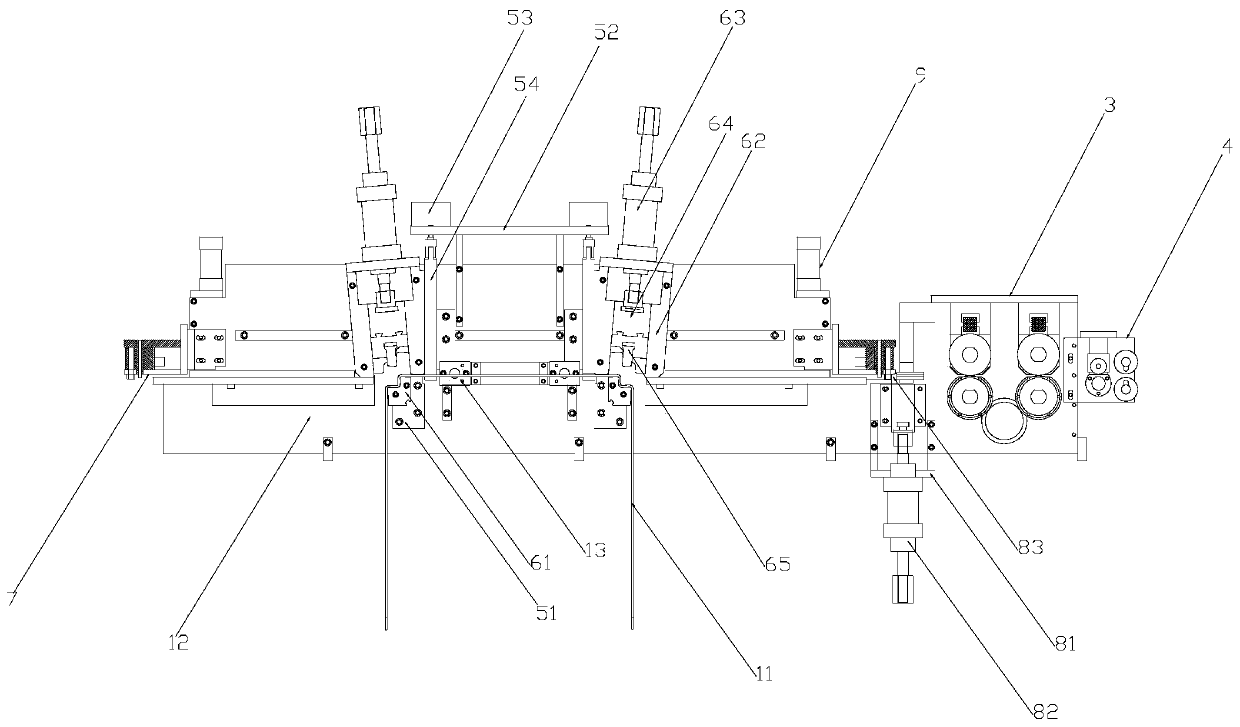

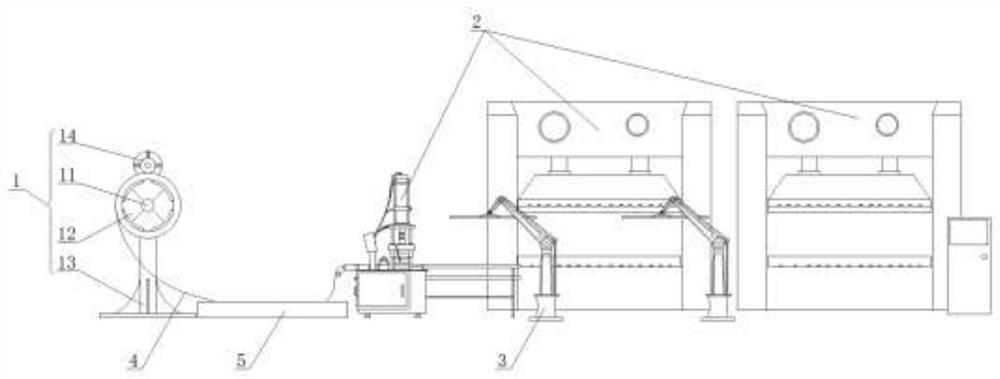

Fully-automatic single blanking mechanical arm

ActiveCN104070558AGet rid of influenceSolve labor intensityMetal working apparatusPunch pressInstability

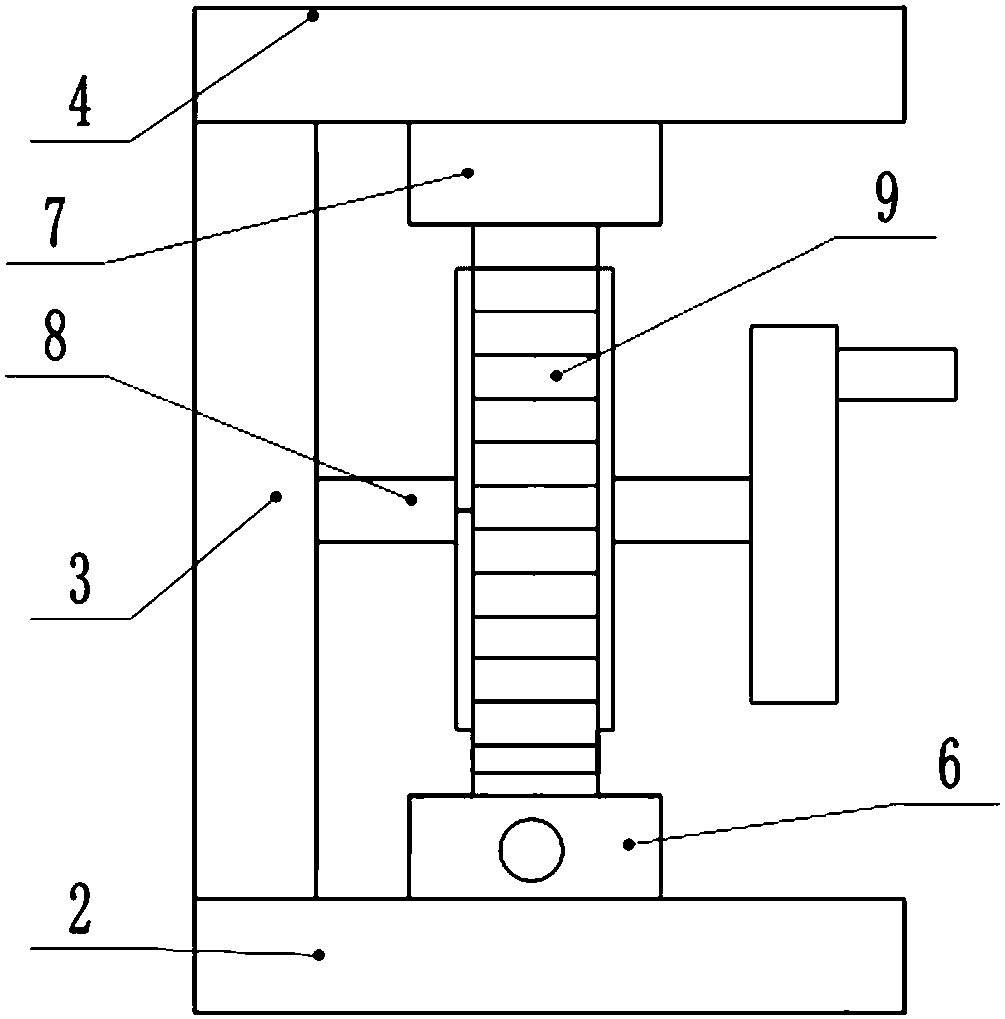

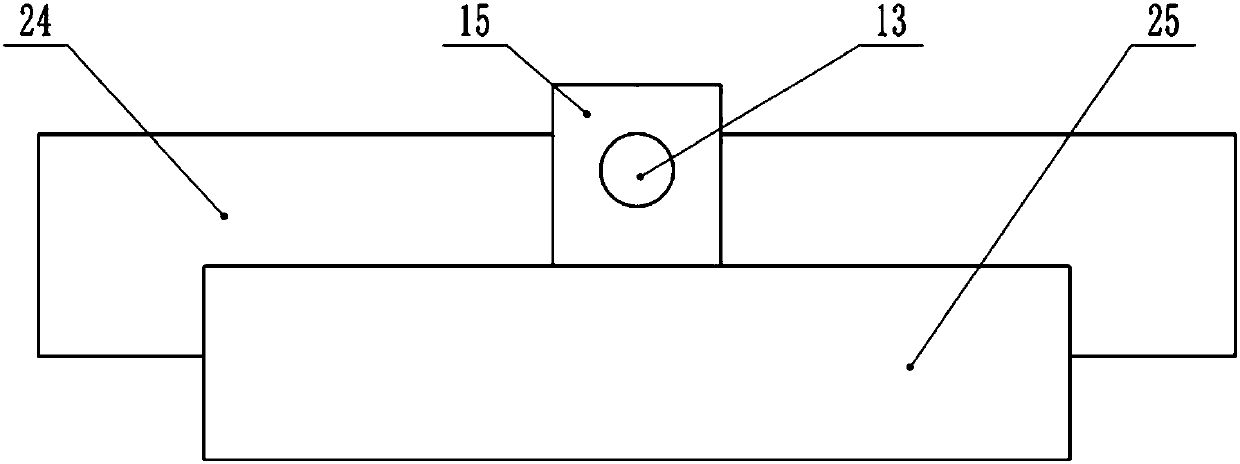

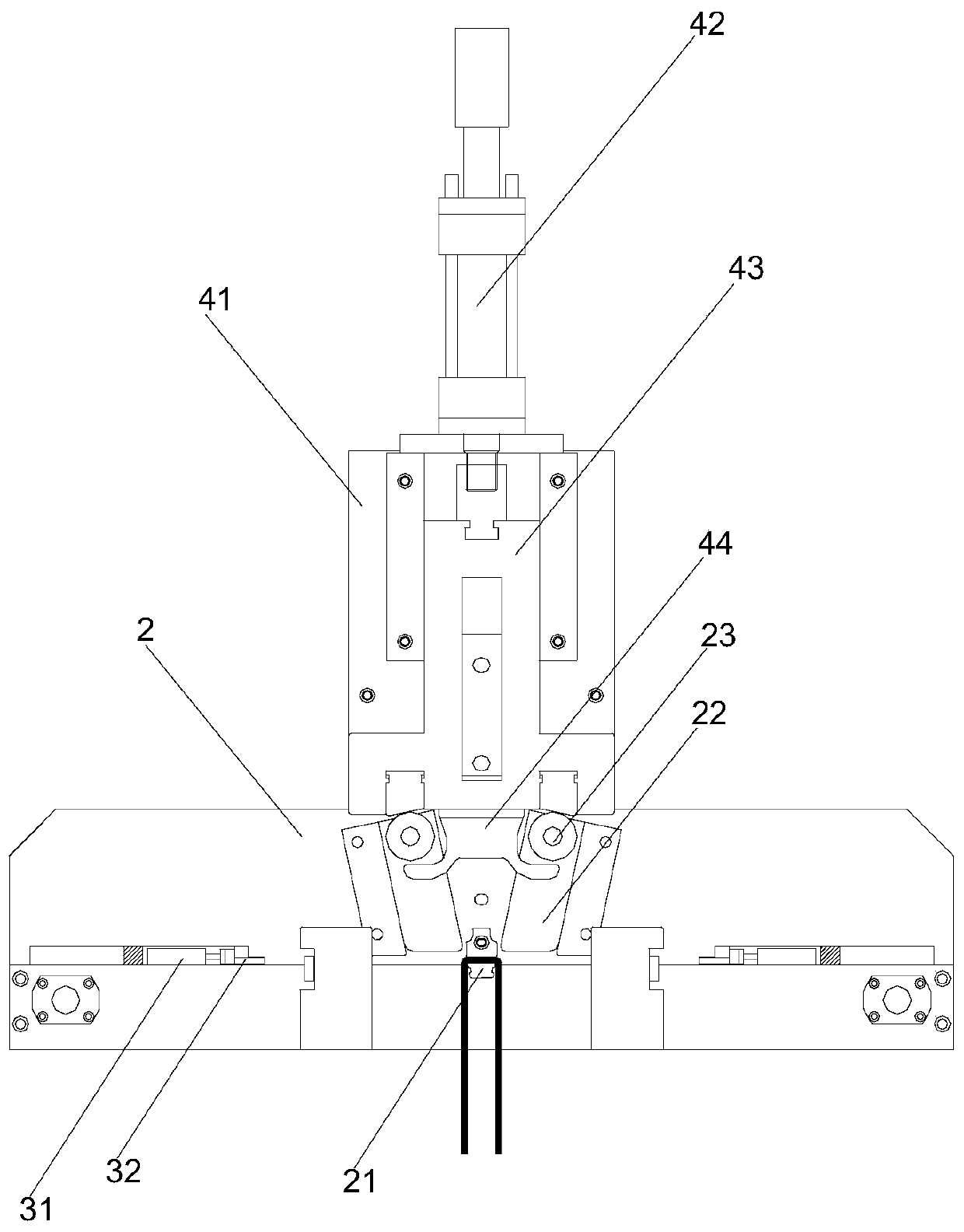

The invention provides a fully-automatic single blanking mechanical arm. A loading plate device, a loading arm device, a blanking device, a horizontal conveying device, an unloading arm device, an upper partition paper device and a finish product collecting device are mounted on an existing punch press to form an excellent structural design, so that the fully-automatic single blanking mechanical arm can complete operations of loading, conveying, blanking, movement and the like of FPC (flexible printed circuit) boards; the cooperation of all the parts enables the fully-automatic single blanking mechanical arm to meet the requirements of single production, so that the problems existing in the signal production such as high labor intensity, high work-related injury risk, low production efficiency, large worker quantity and personnel instability can be solved.

Owner:SHENZHEN MAKEN M & E

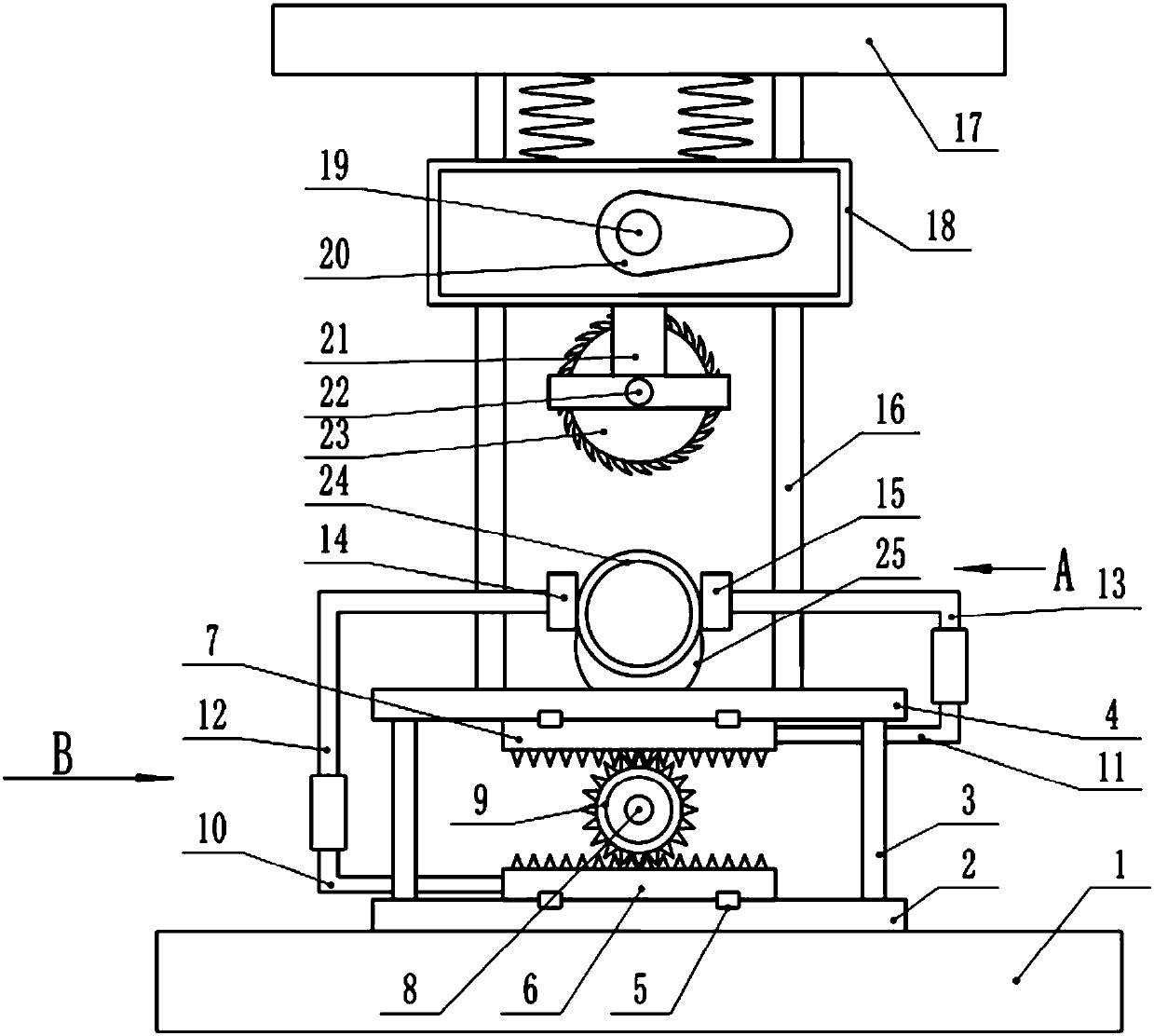

Welded steel pipe welding groove flatly-cutting device capable of being stably fixed

InactiveCN107695437AAvoid displacementAvoid hurtingMetal sawing devicesInterference fitArchitectural engineering

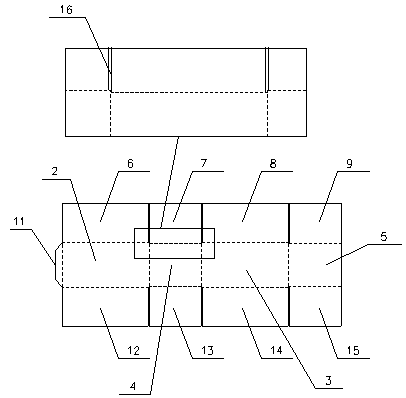

The invention discloses a welded steel pipe welding groove flatly-cutting device capable of being stably fixed. The device comprises a base, a lower rack, an upper rack, a left clamping block, a rightclamping block, a movable sliding frame, a driving motor, a cam and a cutting motor. The other end of a first telescopic rod is in threaded connection with the left clamping block, one end of a second connection rod is in threaded connection with a second telescopic rod, the other end of the second telescopic rod is in threaded connection with the right clamping block, an output shaft of the driving motor is provided with the cam forwards through interference fit, the movable sliding fame is installed on a second supporting column in a sliding mode, a cutting motor is fixedly installed insidea fixing support, and an output shaft of the cutting motor is connected with a cutting wheel. The left clamping block and the right clamping block are arranged to achieve the effect of clamping a steel pipe, the steel pipe is prevented from being shifted in the cutting process, on one hand, cutting precision can be ensured, on the other hand, the steel pipe can be prevented from being popped outto injure people in the cutting process, and therefore operation safety is greatly improved.

Owner:王宏亮

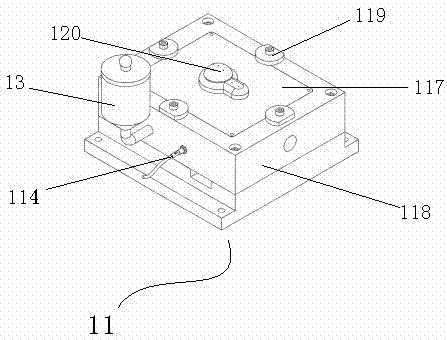

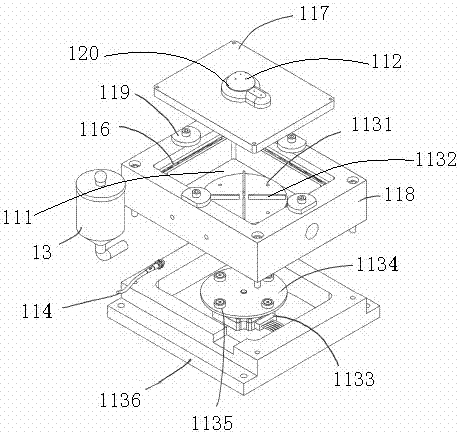

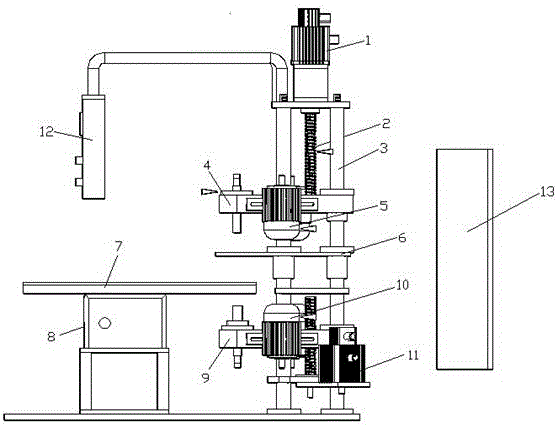

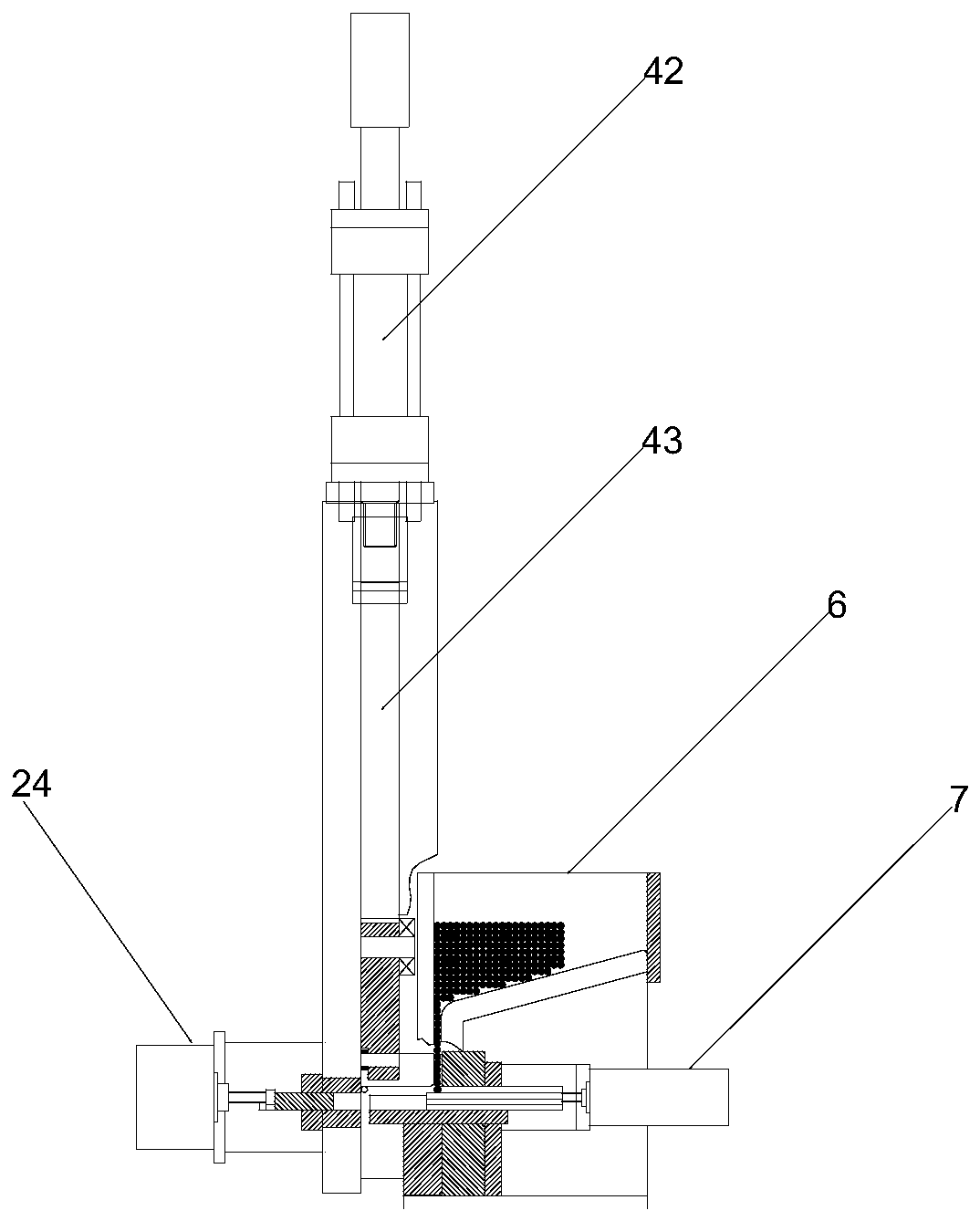

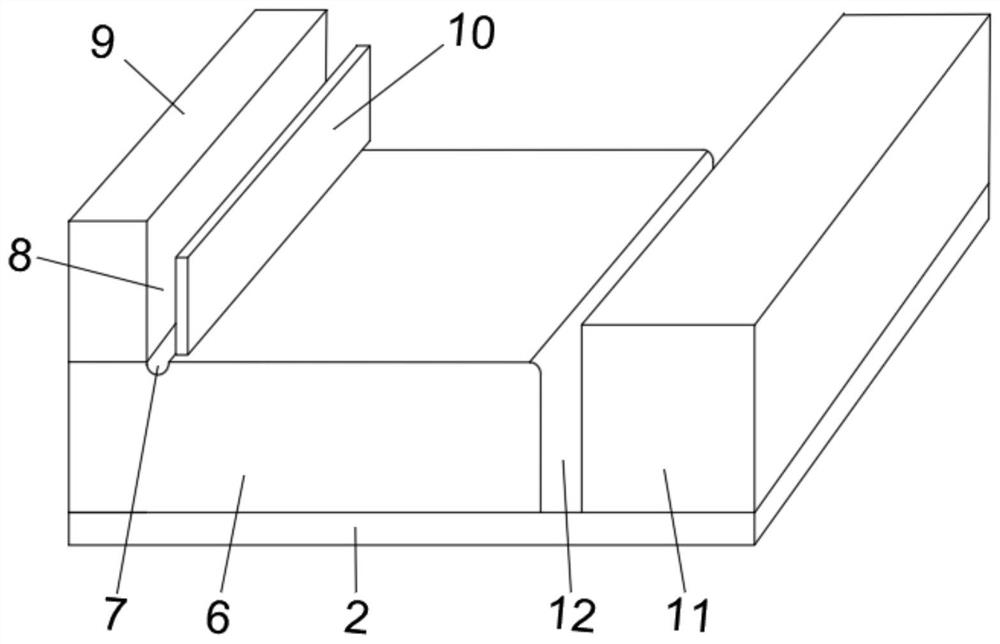

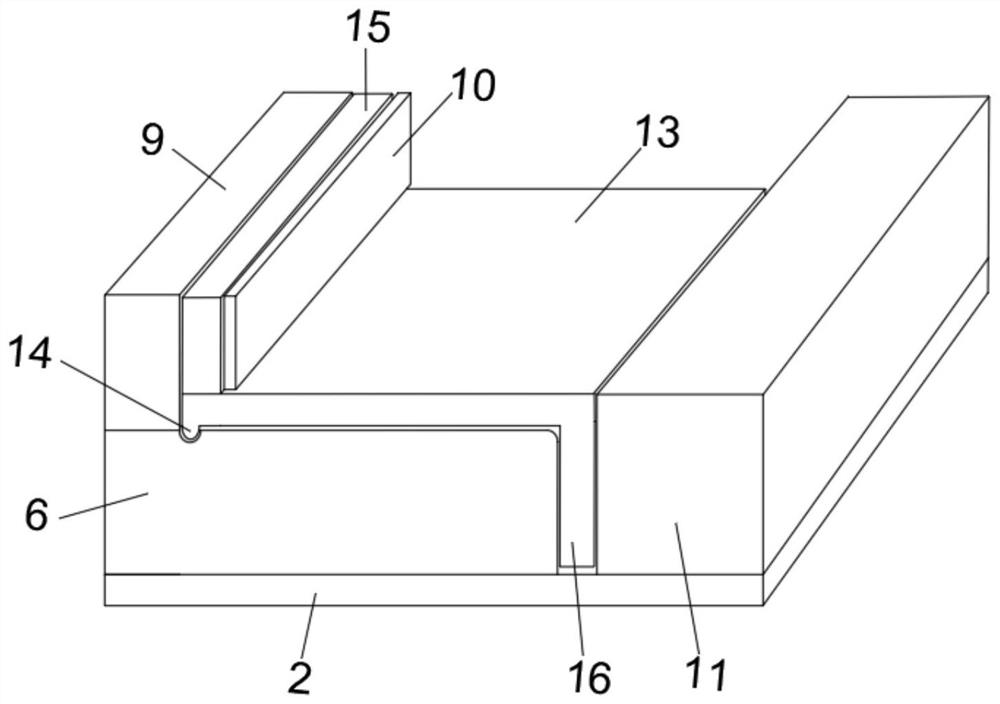

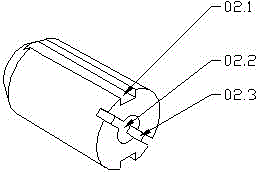

Ink supply device, pad printing machine comprising same and method for controlling ink supply device

InactiveCN102632702AIngenious structureEasy to controlTransfer printingPrinting press partsPad printingEngineering

The invention provides an ink supply device, a pad printing machine comprising the same and a method for controlling the ink supply device, which are used for pad printing operation for coating surfaces of plastic toys and the like, realize coating of the toys with large change of curves, can overcome shortcomings of traditional pad printing equipment, and improve production efficiency and guarantee coating quality. The ink supply device comprises an ink supply box with an internal cavity, an ink opening communicated with the cavity is arranged on the top of the ink supply box, and the ink supply device is further provided with a squeezing device used for squeezing out ink in the cavity to the ink opening. The pad printing machine with the ink supply device comprises the ink supply device, a pad printing head component, a pad printing head transmission component, a plastic part fixing component, a control unit and a framework, the pad printing head component is used for printing a plastic part to be printed, the pad printing head transmission component is used for moving the pad printing head component, the plastic part to be printed is fixed by the aid of the plastic part fixing component, the ink supply device, the plastic part fixing component, the pad printing head transmission component and the control unit are mounted on the framework, and the pad printing component is mounted on the pad printing head transmission component.

Owner:中扩实业集团有限公司

Double-head automatic numerical control drilling machine

InactiveCN105904596ARealize automatic drilling processMeet processing needsWorking accessoriesStone-like material working toolsNumerical controlHigh density

The invention discloses a double-head automatic numerical control drilling machine which comprises an upper servo motor, a lower servo motor, a numerical control operation box and a numerical control power box. An upper transmission ball screw is in transmission connection with an upper bearing block through a transmission nut. A fixing pressing plate is arranged at the lower end of a driving motor. The lower servo motor is in transmission connection with a transmission nut at the bottom of a lower bearing block through the upper transmission ball screw, a rotary motor is arranged on the lower bearing block, a high-density cutter is disposed on the left side of the lower bearing block, and a rotary plate is arranged at the upper end of the high-density cutter. The double-head automatic numerical control drilling machine can achieve automatic drilling of parts, work programs of a machine tool and workpiece positions are set according to actual machining requirements, the machine tool is controlled to automatically drill the parts, the number and the positions of drilled holes meet machining requirements, precision is high, errors are small, efficiency is high, labor is saved, and industrial injury risks are reduced.

Owner:胡燕娇

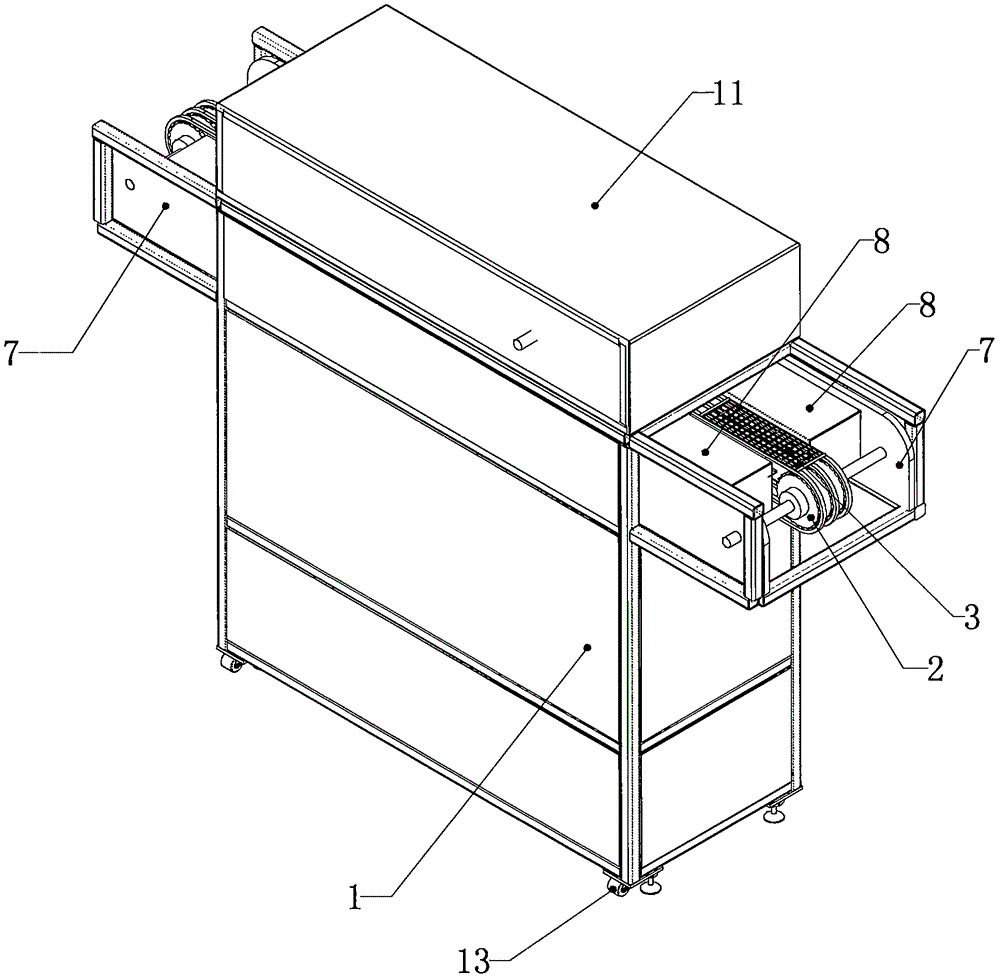

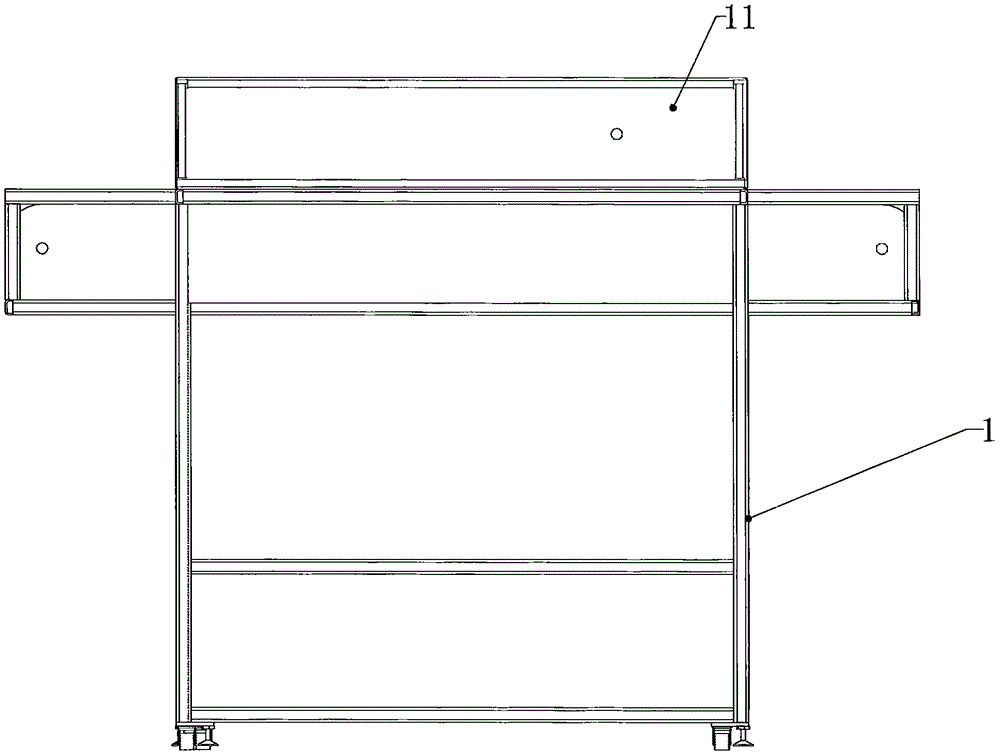

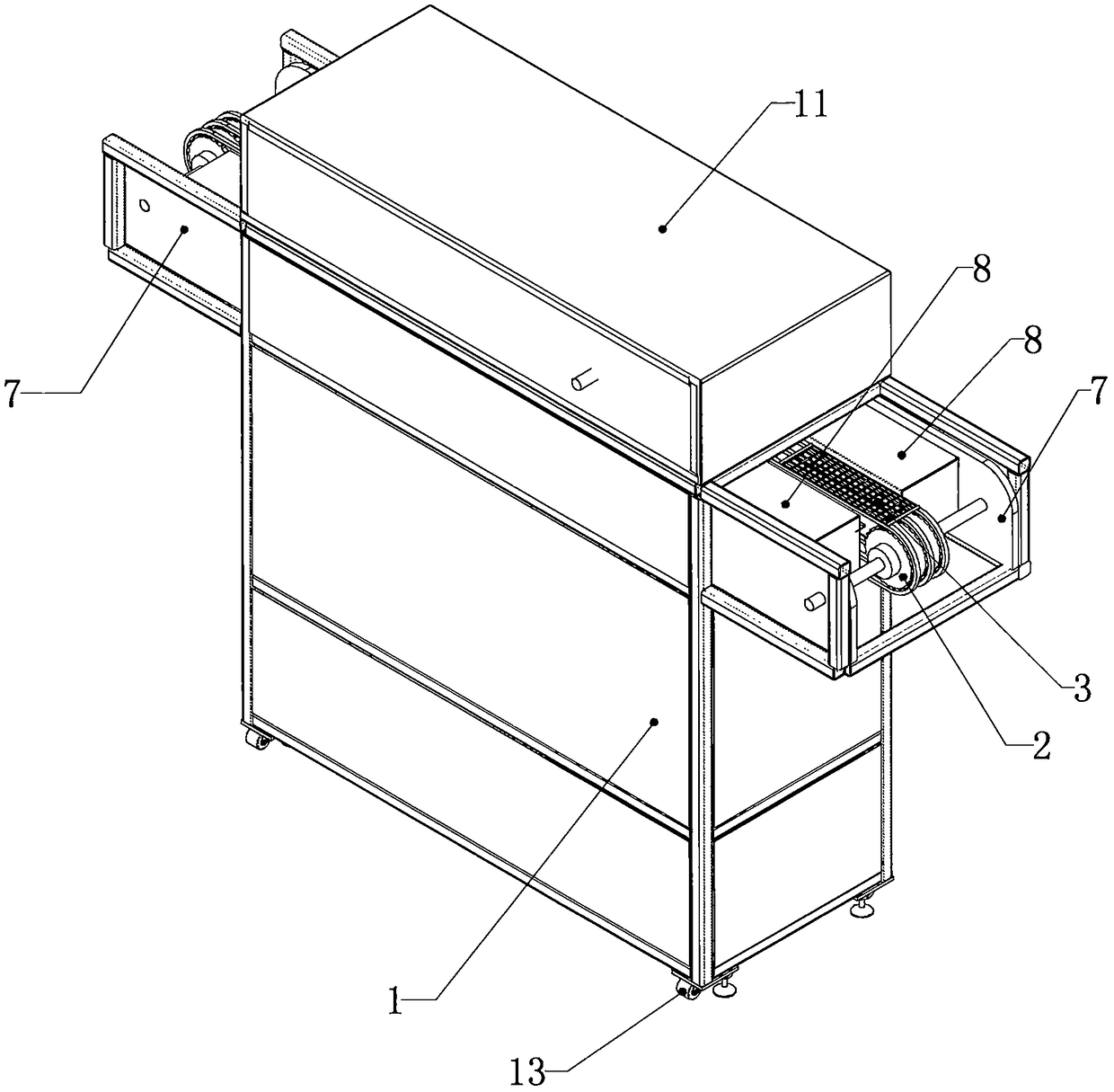

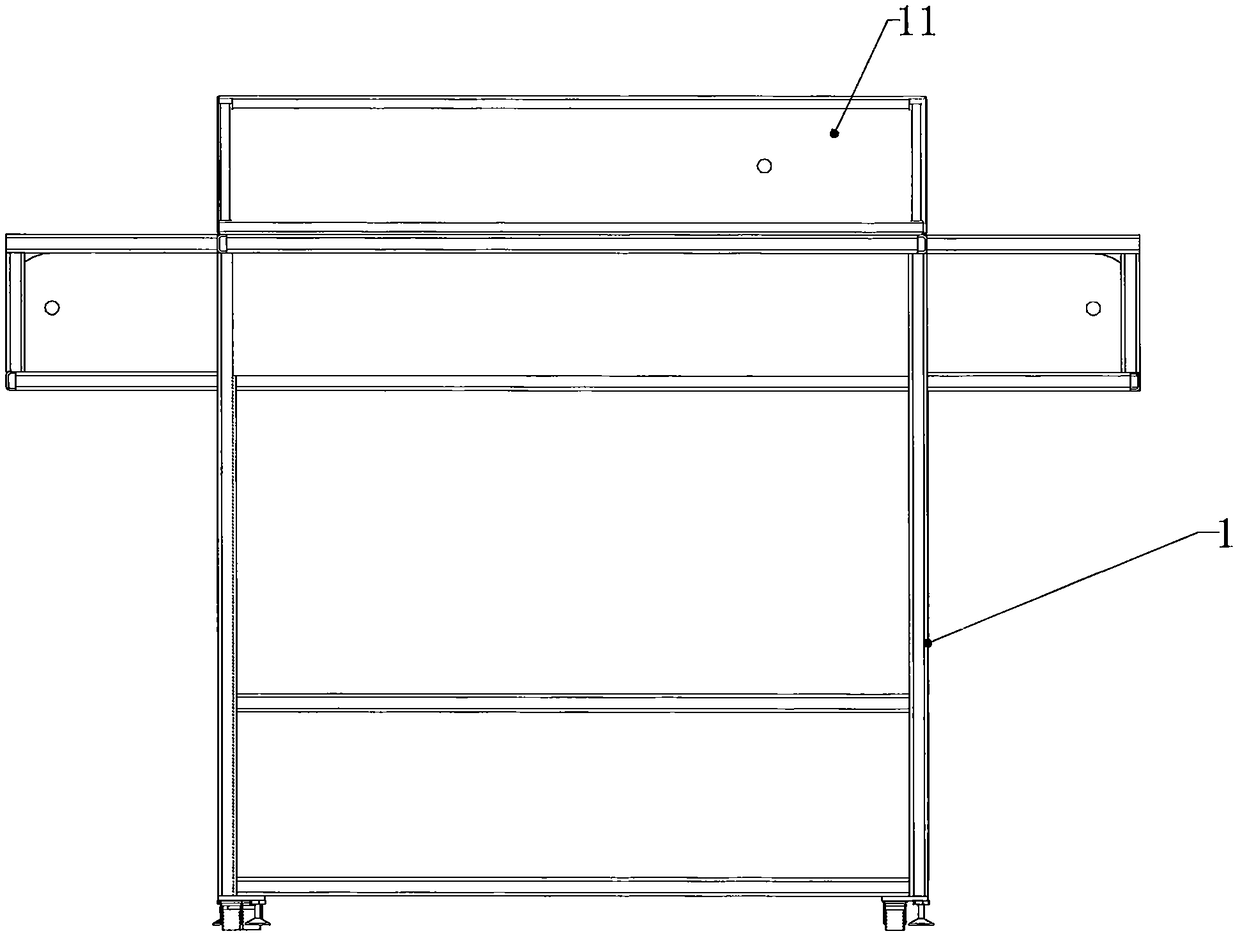

Sand blasting machine and method for removing plastic-product rough edge and gas marks through sand blasting machine

ActiveCN106272099AResolve surface burrsSolve the problem of air marksAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

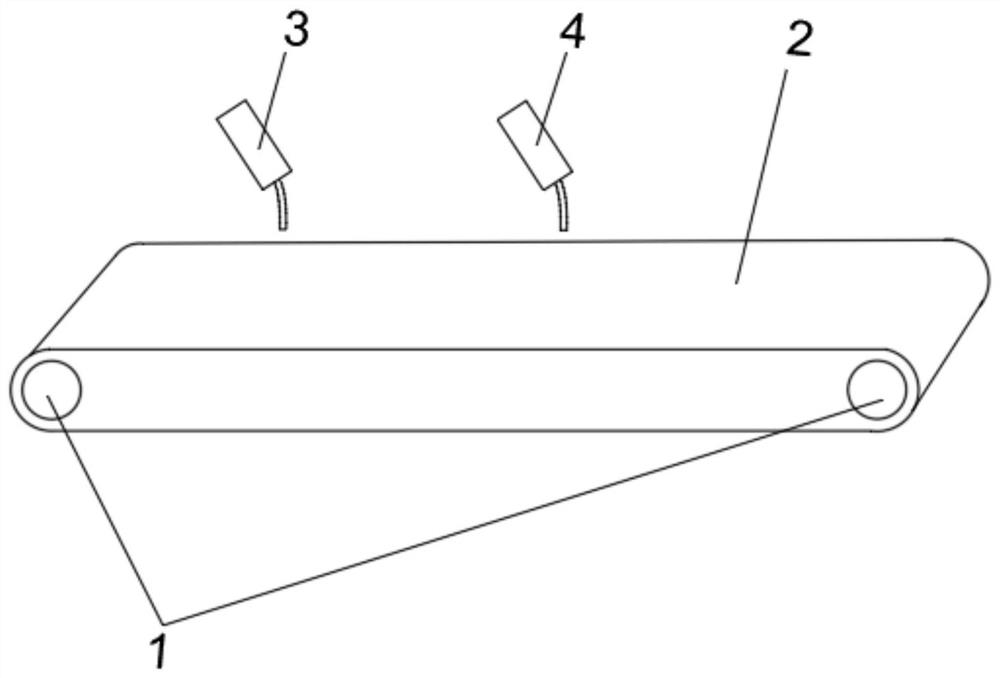

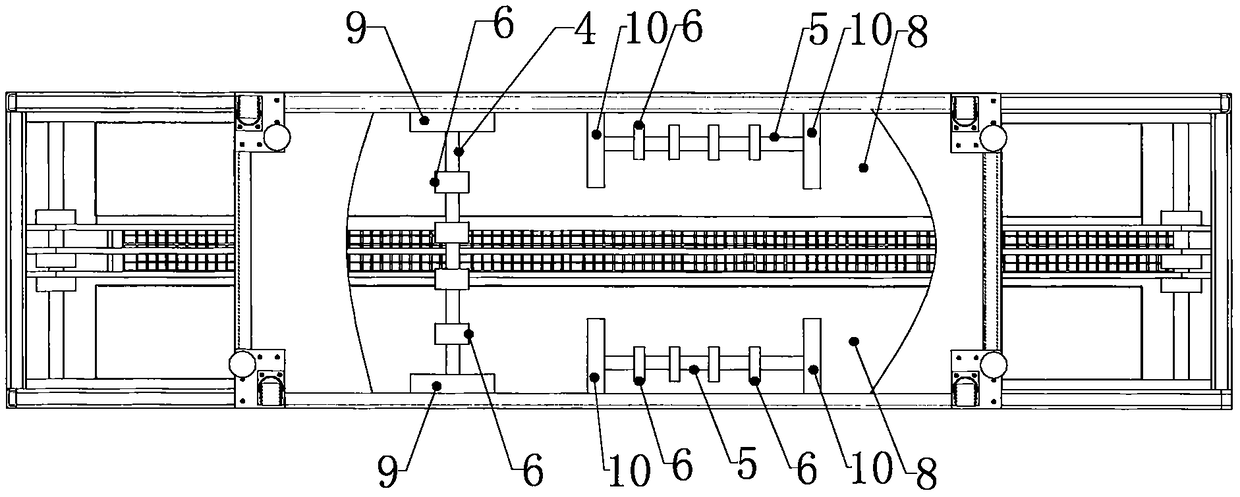

The invention relates to a sand blasting machine. The sand blasting machine comprises a machine frame, a conveying device and a sand blasting device. The conveying device comprises belt wheels and a conveying belt; the two belt wheels are arranged at the left end and the right end of the machine frame respectively, the conveying belt is arranged on the belt wheels and driven by the belt wheels. The sand blasting device comprises a first rotating shaft and second rotating shafts; the first rotating shaft is basically perpendicular to the conveying direction of the conveying belt, the second rotating shafts are basically parallel to the conveying direction of the conveying belt, the two second rotating shafts are located on the front side and the back side of the conveying belt respectively, and blasting heads for blasting sand are arranged on the first rotating shaft and the second rotating shafts respectively and located on the conveying belt. According to the sand blasting machine, as the blasting heads are arranged, plastic-product rough edge and gas marks can be effectively removed, the processing efficiency is high, and the industrial injury risk is low. The invention also relates to a method for removing plastic-product rough edge and gas marks through the sand blasting machine, and operators can effectively remove plastic-product rough selvedges and gas marks with the method.

Owner:周选保

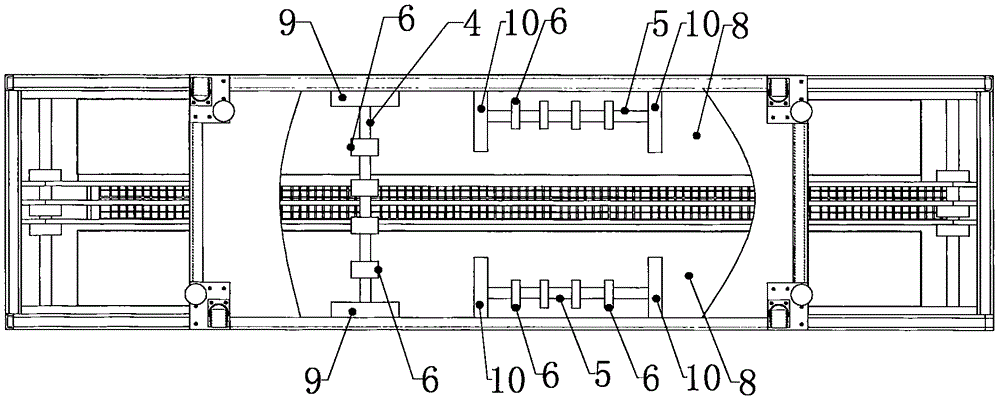

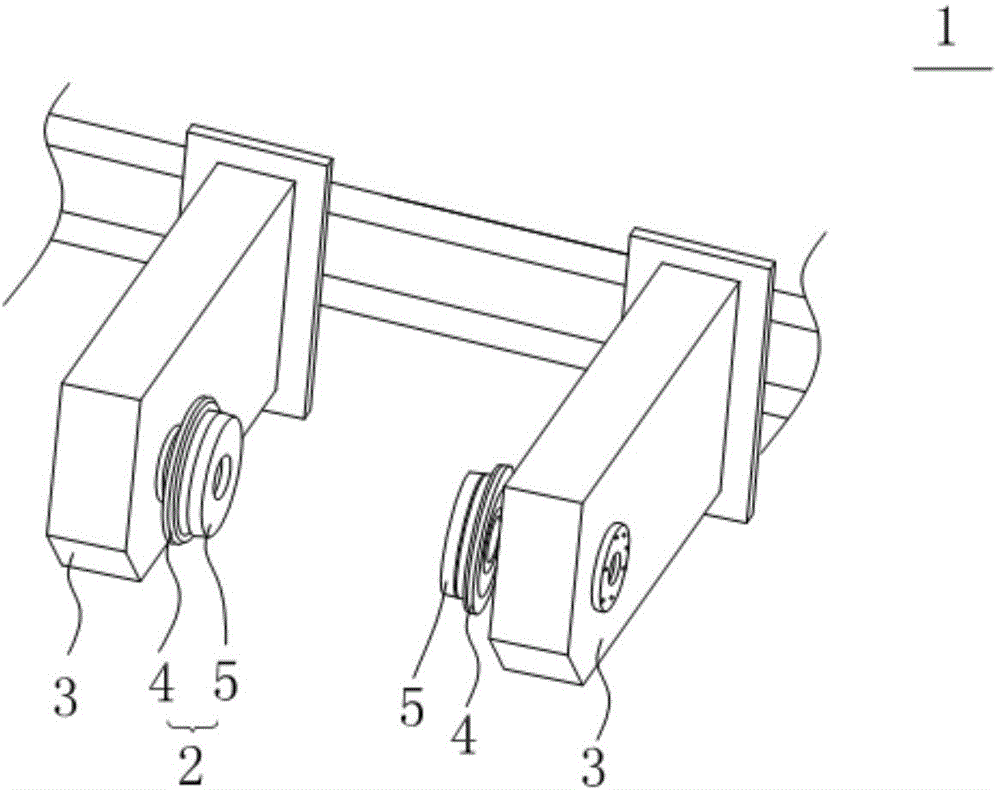

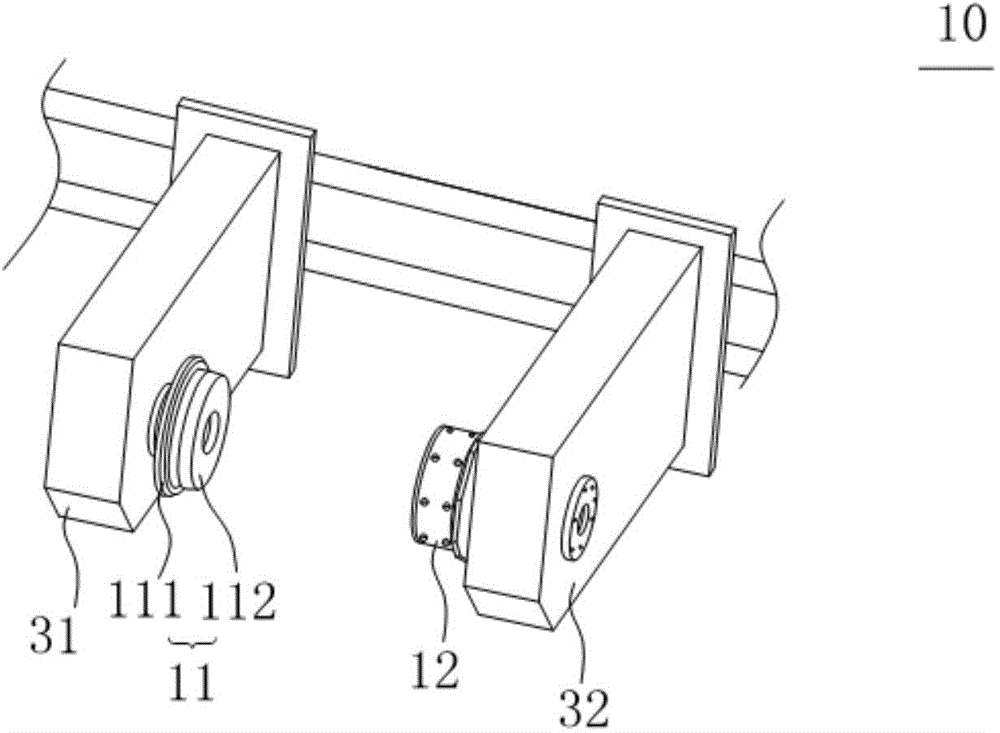

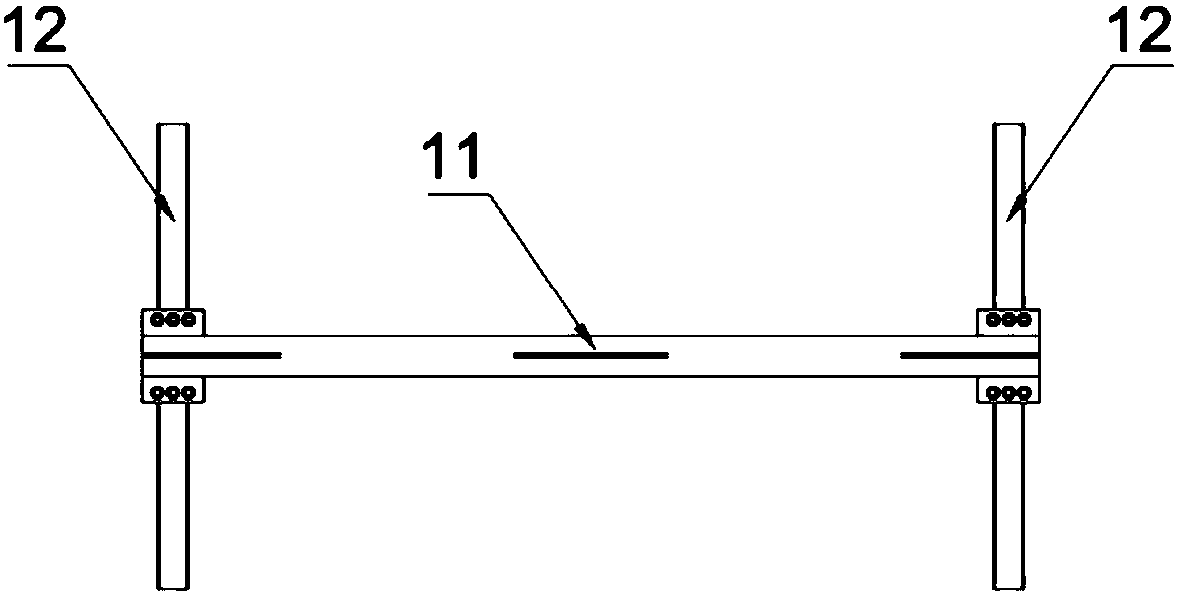

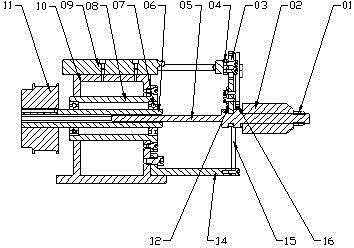

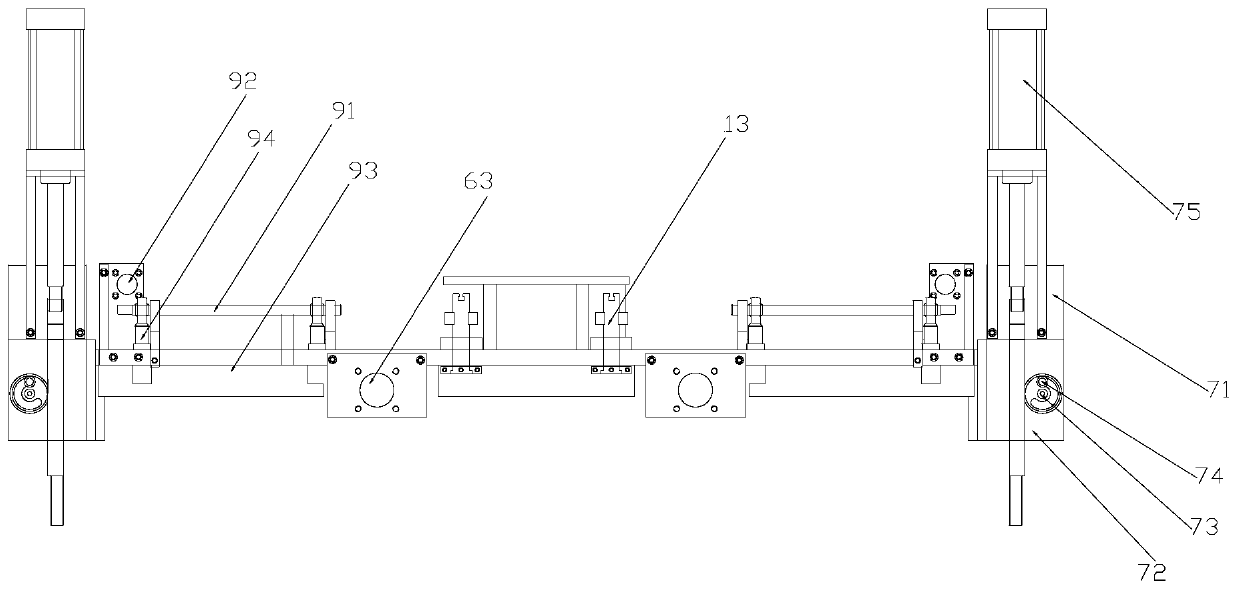

Clamping device and winding and unwinding device

ActiveCN104860096AExtended tension control rangeReduce labor intensityWebs handlingConductor CoilSlip ring

The invention provides a clamping device and a winding and unwinding device. The clamping device comprises a first clamping head, a second clamping head, a plurality of friction plates, a friction ring, a slip ring, and an end cover, wherein the second clamping head comprises a first shaft core; the first shaft core comprises a first end part and a first shaft part; a plurality of grooves are formed in the first shaft part; each friction plate partially protrudes from a corresponding groove; the friction ring sleeves the first shaft part; the slip ring sleeves the first shaft part; the friction plates are positioned between the slip ring and the first shaft part, and in contact with the slip ring; the friction ring is positioned between the first end part and the slip ring; a plurality of raised keys are formed on the outer ring surface of the slip ring; under stress, the raised keys protrude from the outer ring surface of the slip ring to be tightly propped against a coil core; the end cover is fixed with the end, far away from the first end part, of the first shaft part in a combined manner; the friction ring and the slip ring are clamped between the first end part and the end cover. Through the adoption of the clamping device, the problem that in the prior art, the clamping tension of a clamping head is non-adjustable or is inconvenient to adjust, can be solved.

Owner:BENQ MATERIALS

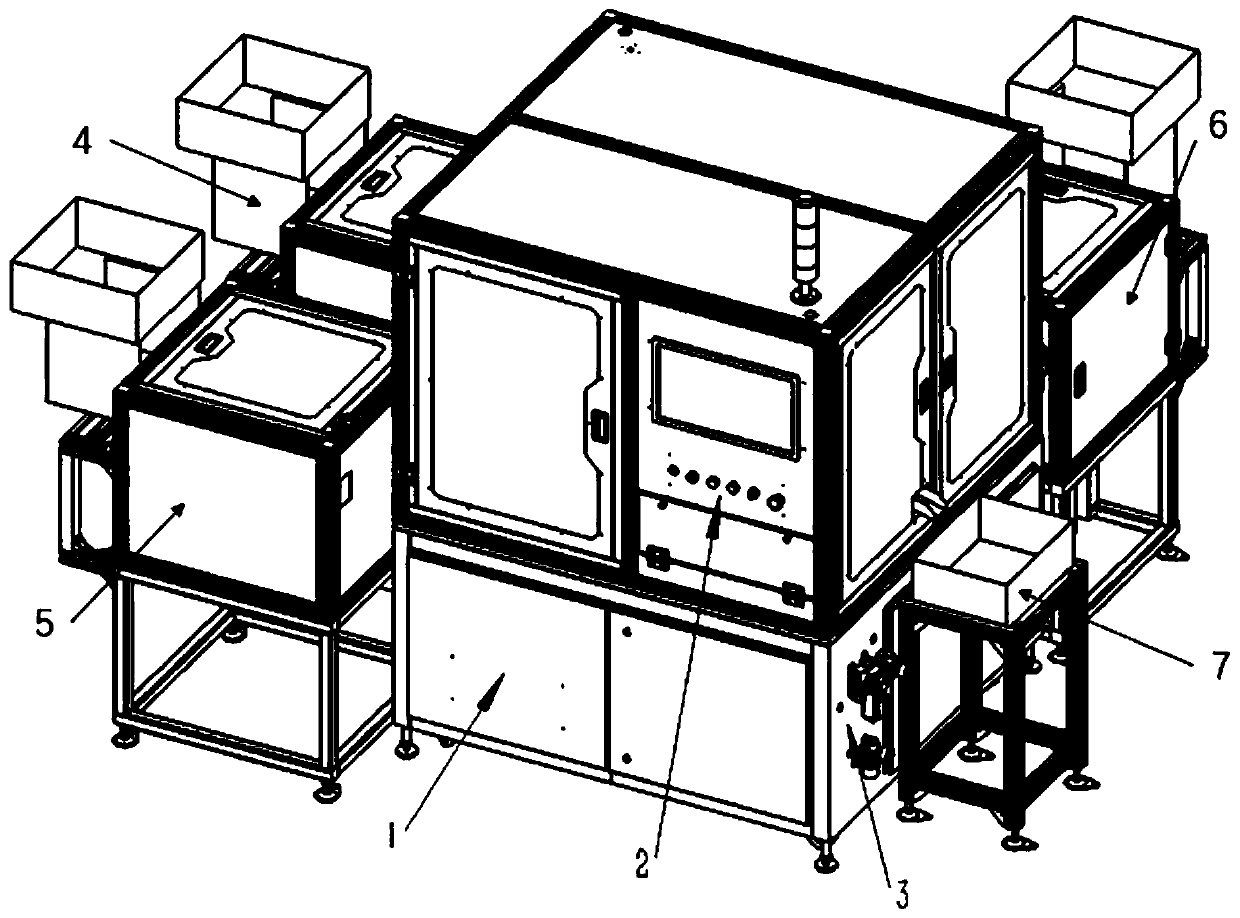

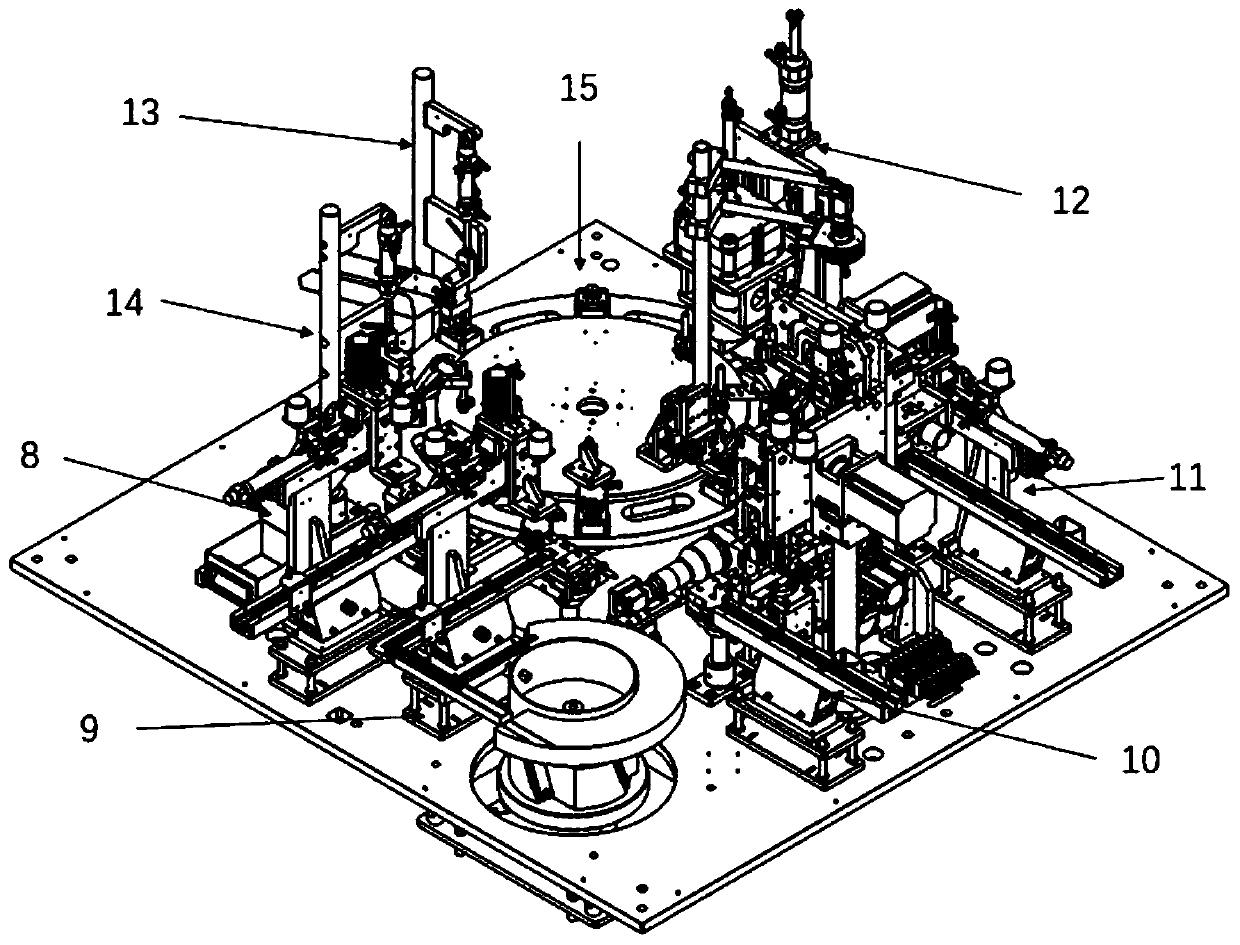

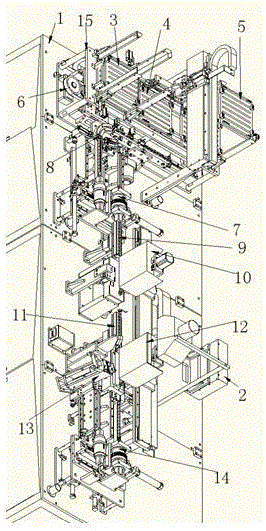

Automatic production equipment for electronic components

PendingCN111014383AEasy to operateRealize the needs of automatic productionMetal-working feeding devicesSortingElectric controlElectronic component

The invention discloses automatic production equipment for electronic components. A produced product is composed of a base, a gasket, an inner claw and an end cover, the gasket is placed on the base,then the inner claw is placed in the base, then the end cover is arranged on the base in a sleeving mode, pressing riveting is carried out, and therefore the equipment is designed. The equipment comprises an electric control box, an operation panel, a pneumatic control assembly, a base feeding assembly, an inner claw feeding assembly and an end cover feeding assembly, each feeding assembly comprises a feeding funnel, a vibration disc, a direct vibration feeder and a part inductive sensor, and mounting bottom plates are arranged between the upper part and the lower part of a box body, and eachmounting bottom plate comprises a base feeding mechanism, a gasket feeding mechanism, an inner claw feeding mechanism, an end cover feeding mechanism, a rivet pressing mechanism, a qualified product discharging mechanism and an unqualified product discharging mechanism.

Owner:南京微伽自动化技术有限公司

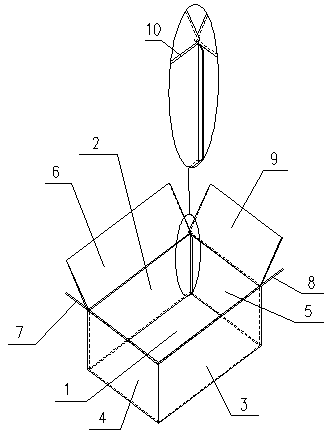

High foaming plastic packaging box

The invention discloses a high foaming plastic packaging box which is manufactured by folding and fixing a high foaming plastic plate. The high foaming plastic plate comprises a plastic high foaming layer in the middle and an external smooth high-tenacity high-density foaming layer or non-foaming plastic layer. The foaming ratio of the plastic high foaming layer in the middle is 1-40, and the highfoaming plastic plate is manufactured through compounding, extrusion, gluing or hot press molding. The high foaming plastic packaging box comprises a box body, the box body is of an integrated structure, the box body comprises a bottom plate, a left side plate, a right side plate, a front face plate, a rear face plate and an upper top plate, and the left end of the left side plate is provided with a connection rod. The high foaming plastic packaging box has the advantages of being low in density, high in tenacity, good in bearing performance, pressure resistance and buffer performance, foldable and capable of being repeatedly used.

Owner:GUANGDONG BENDI NEW MATERIAL TECH

CNC automated processing system and method

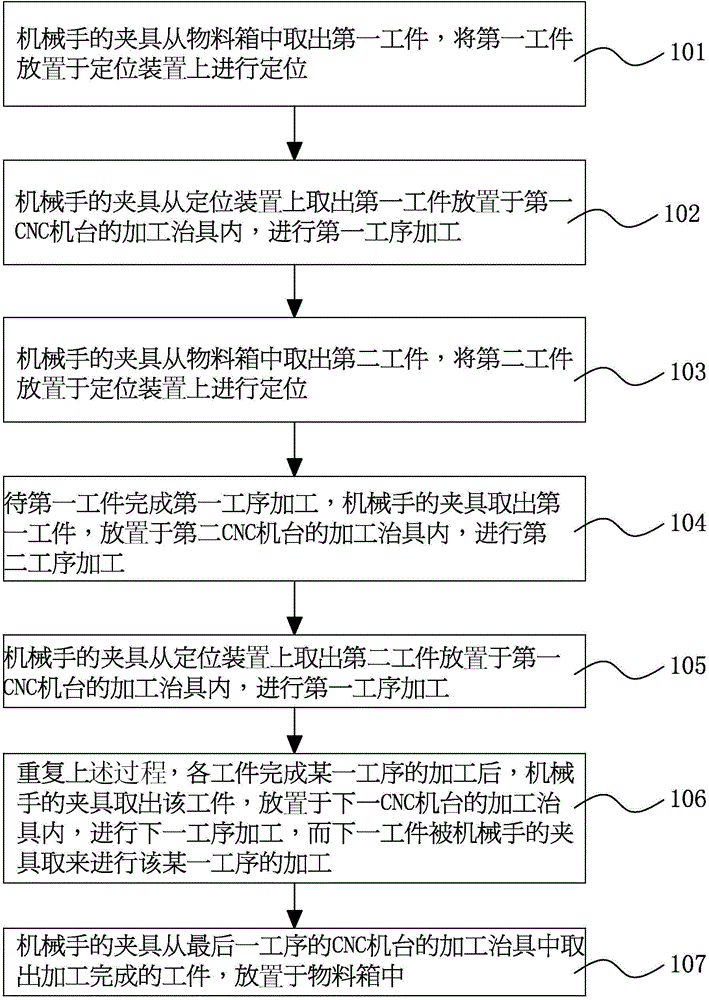

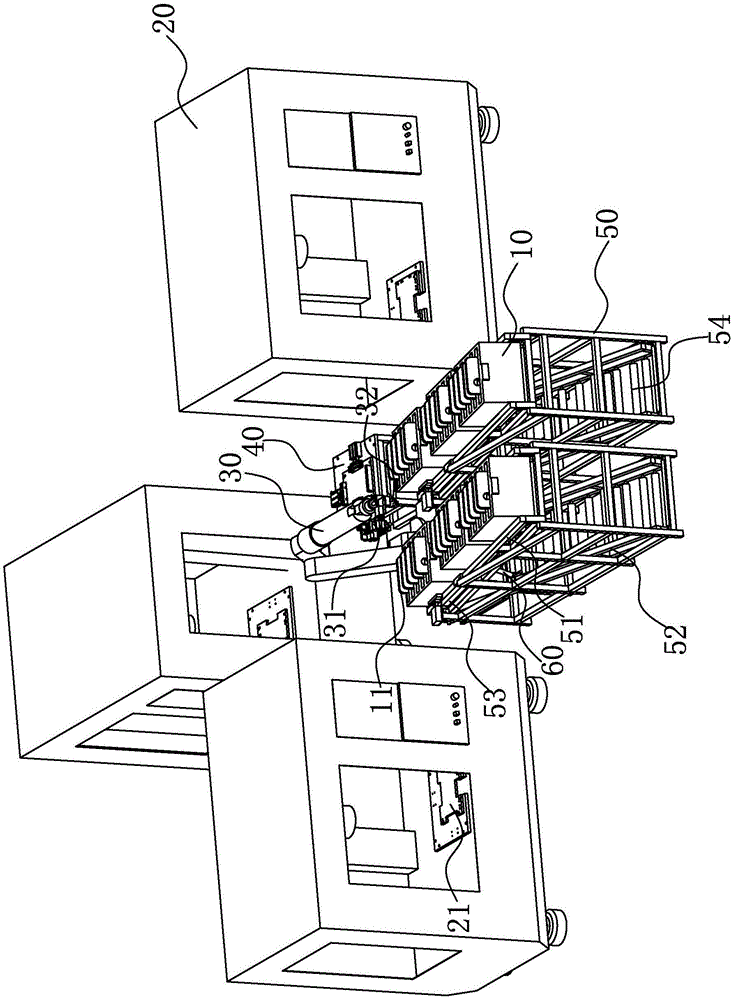

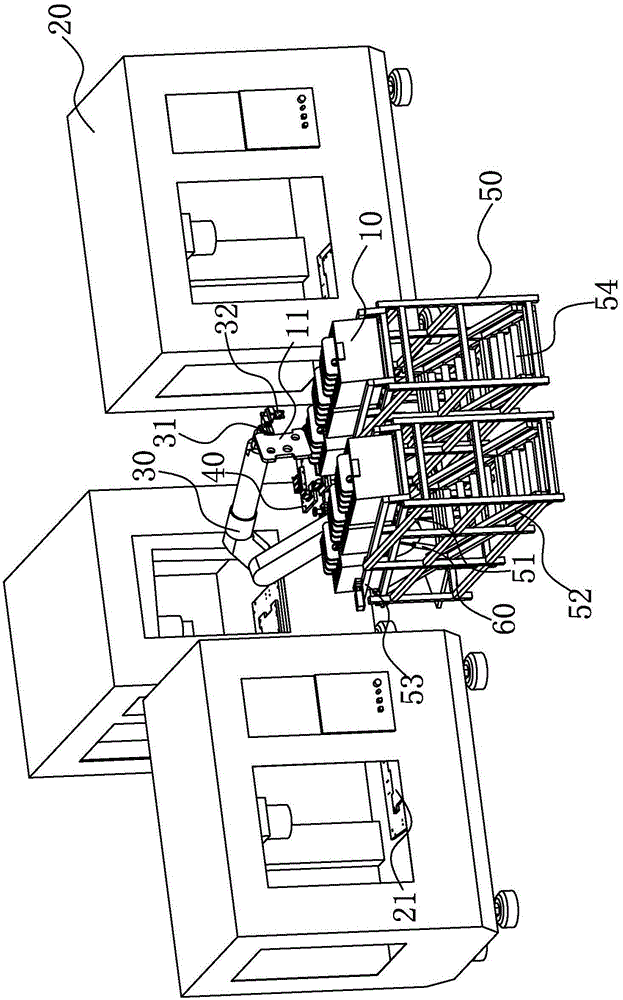

InactiveCN105834838AAvoid frequent operationsSave man hoursMetal working apparatusEngineeringManipulator

The invention discloses a CNC automated processing system and method. The device comprises a material box, multiple CNC machines, a manipulator and a locating device. Multiple workpieces to be machined are arranged in the material box side by side. A machining region is enclosed by the multiple CNC machines and the material box. All the CNC machines perform machining operation on the workpieces in different procedures and are internally provided with machining fixtures. The manipulator is arranged in the machining region and the end part of the manipulator is provided with a clamp used for clamping the workpieces. A controller is arranged in the manipulator and in signal connection with the all the CNC machines, the machining fixtures and the clamp, which is used for controlling on-off of the all the CNC machines, switches of the machining fixtures and controlling the clamp to take and pick the workpieces. The locating device is arranged in the machining region and used for locating the workpieces. The method utilizes the device to transfer the workpieces in different procedures so that time and labor can be saved, and errors caused by frequent operation of an operator and industrial injury danger are avoided.

Owner:KUNSHAN HANDING PRECISION METAL CO LTD

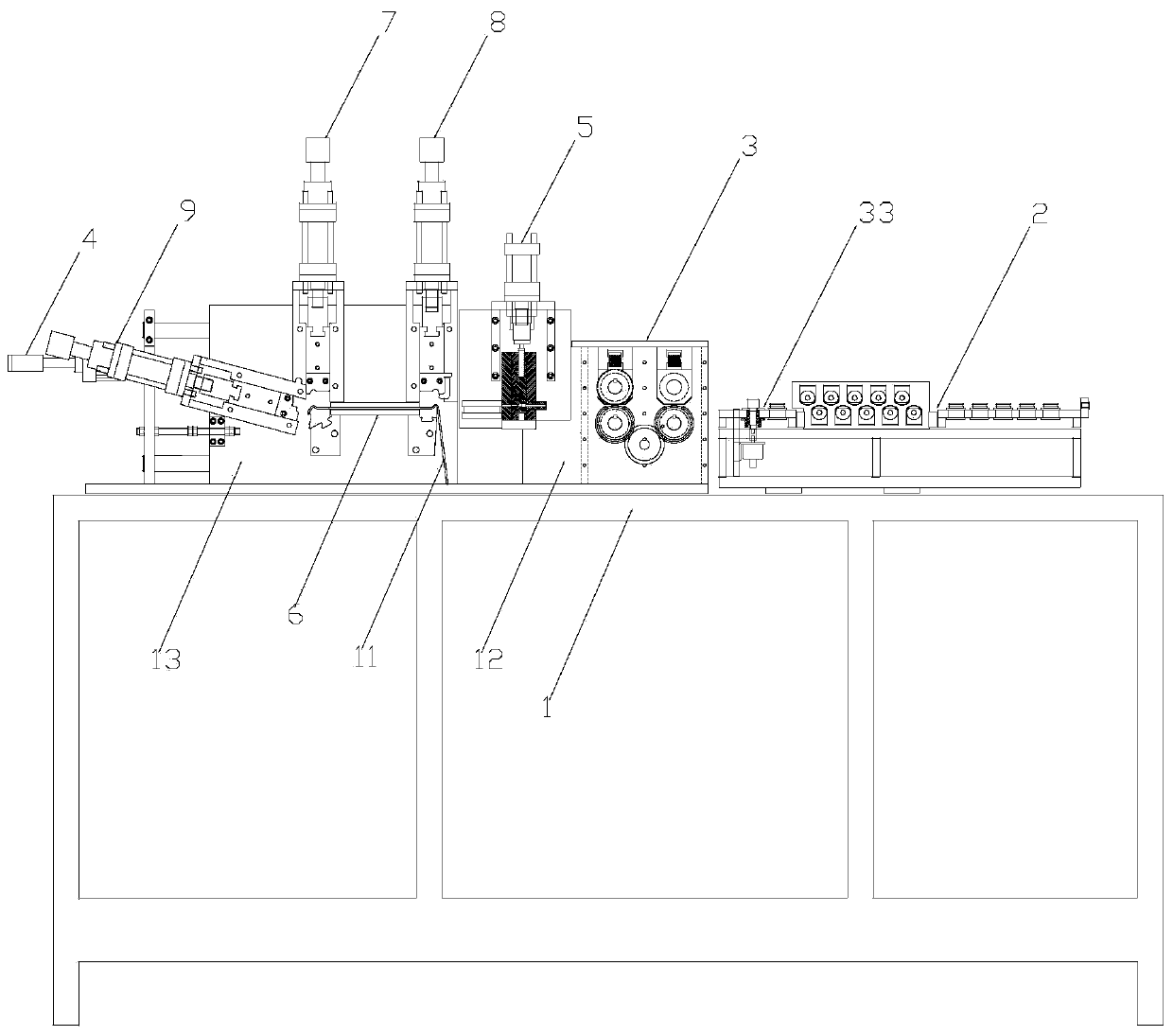

Wavy wire molding machine

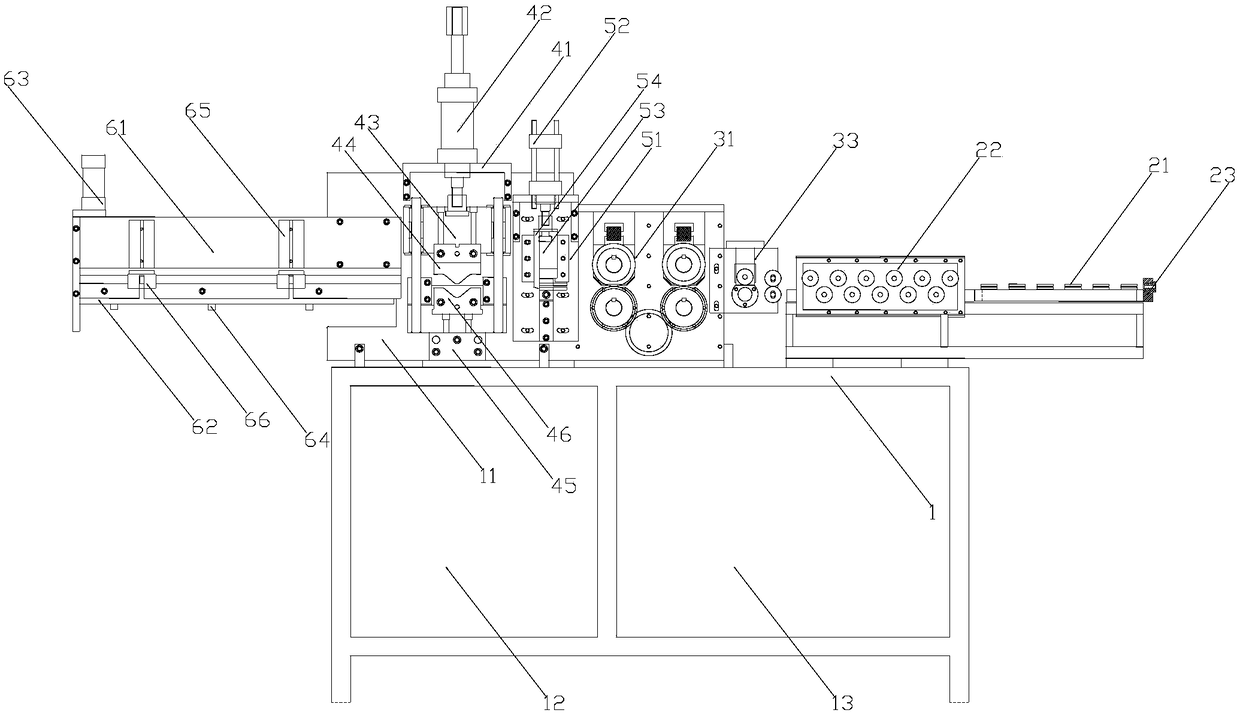

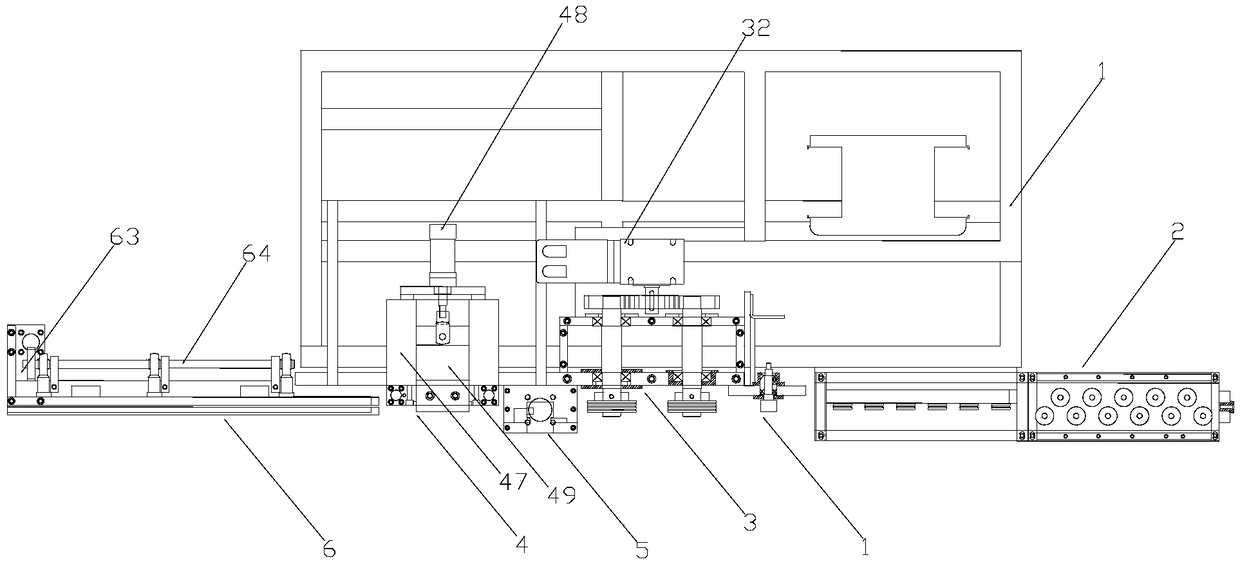

The invention belongs to the technical field of wire material molding equipment and particularly provides a wavy wire molding machine. The wavy wire molding machine comprises a rack and an operating platform, a driving portion and a control portion which are arranged on the rack, wherein one side of the operating platform is provided with a wire adjusting mechanism for straightening and flatteningwire materials, the position, at the wire outlet end of the wire adjusting mechanism, located on the operating platform is provided with a wire guiding mechanism for conveying the wire materials, theposition, at the wire outlet end of the wire guiding mechanism, located on the operating platform is provided with a rolling mechanism for rolling and molding the wire materials, the position, between the rolling mechanism and the wire guiding mechanism, located on the operating platform is provided with a wire cutting mechanism for cutting off the wire materials, the position, at the wire outletend of the rolling mechanism, located on the operating platform is provided with a wire outlet mechanism, and driving circuits and control circuits on the wire guiding mechanism, the rolling mechanism, the wire cutting mechanism and the wire outlet mechanism are connected to the driving portion and the control portion correspondingly. The wavy wire molding machine is reasonable in structure, highin automation level and production safety factor and beneficial to application and promotion of the wire material machining market.

Owner:徐州奔蓝机械科技有限公司

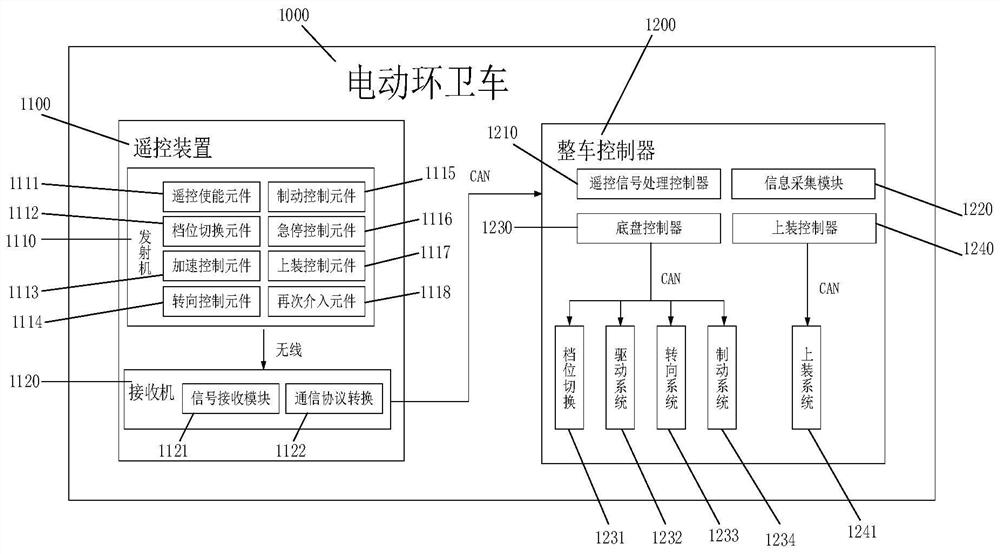

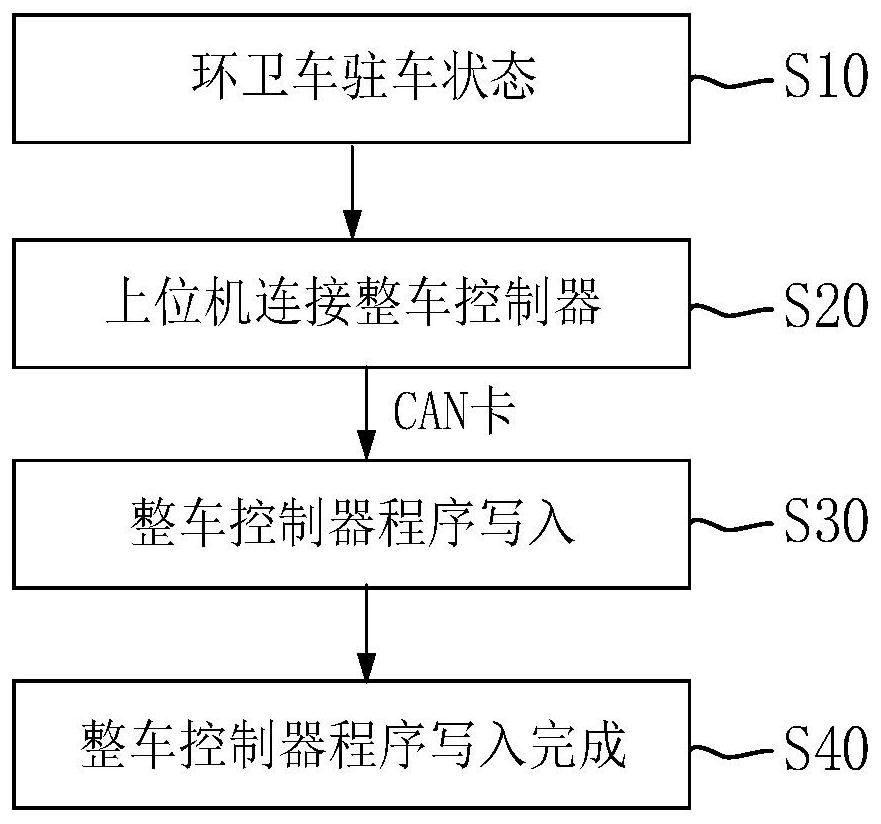

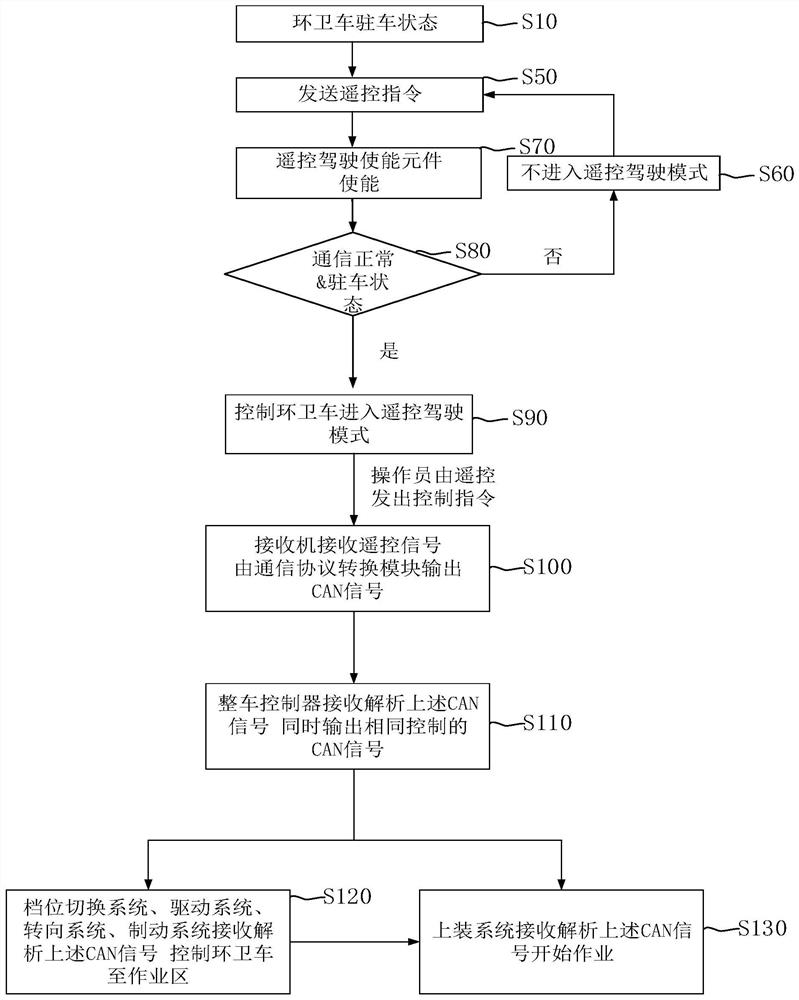

Remote control method and system for electric sanitation vehicle, controller and electric sanitation vehicle

InactiveCN112904825ARealize remote control drivingReduce the risk of work-related injuriesElectric testing/monitoringDriver/operatorControl system

The embodiment of the invention discloses a remote control method and system for an electric sanitation vehicle, a controller and an electric sanitation vehicle. According to the embodiment of the invention, whether a remote control driving mode is started or not is judged according to the collected real-time state information of the electric sanitation vehicle. The remote control driving mode is started, a driving behavior control instruction is sent to the electric sanitation vehicle, and the electric sanitation vehicle is controlled by a gear switching system, a driving system, a steering system and a braking system of a control chassis to run to an operation position. A loading control instruction is sent to the electric sanitation vehicle, and the sanitation vehicle is controlled by a loading control system to enter a working state. Wireless remote control driving of the electric sanitation vehicle can be achieved through the remote control driving system, a driver does not need to climb into and out of a cab every time the electric sanitation vehicle is started and stopped, and therefore the risk rate of related industrial injuries such as knee strain and other joint strain of sanitation workers concentrated in the middle-aged and elderly age can be effectively reduced, and meanwhile, the safety and the high efficiency of environmental sanitation operation are improved.

Owner:成都壹为新能源汽车有限公司

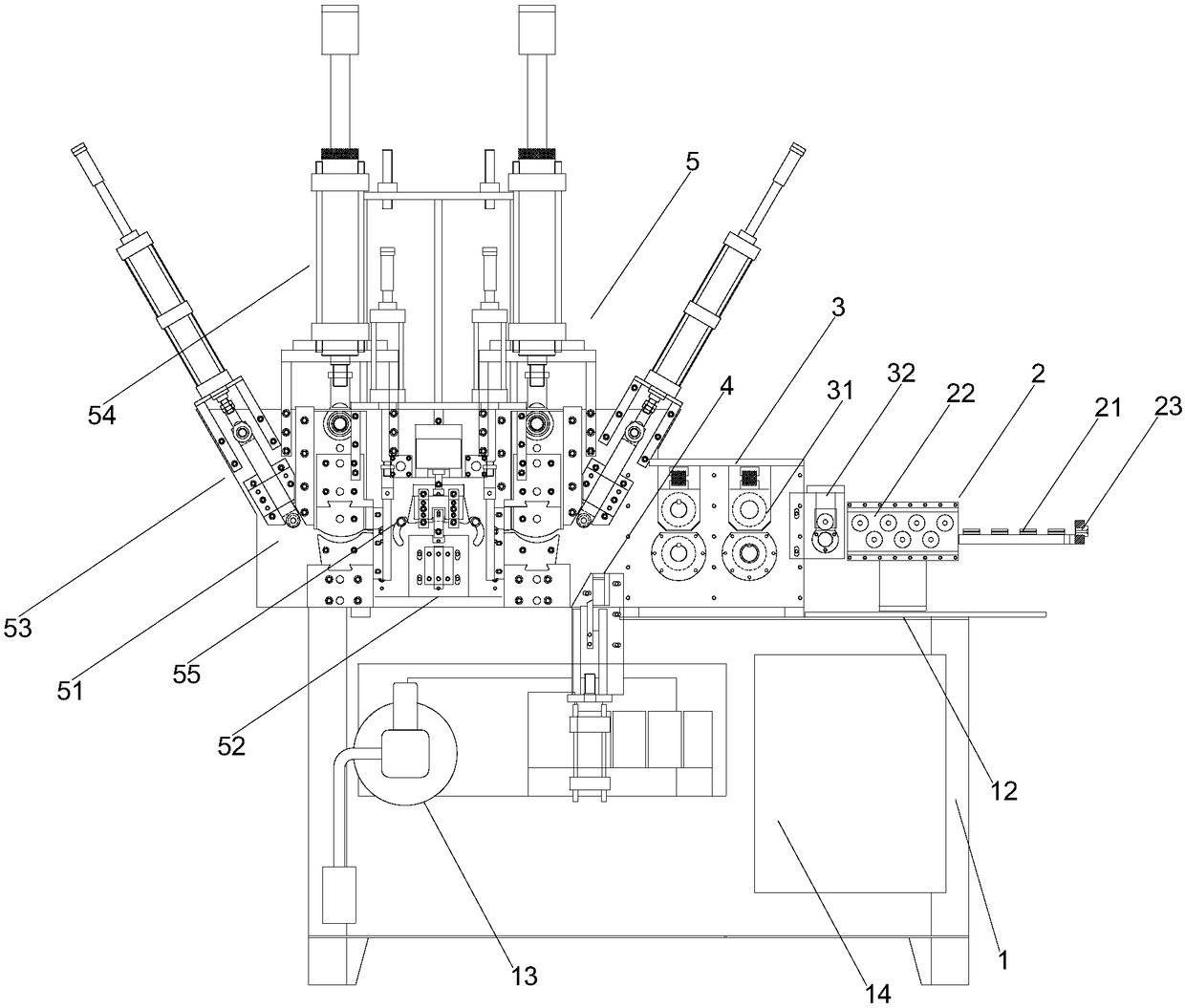

Full-automatic two-dimensional wire bending forming machine

The invention belongs to the technical field of wire processing equipment, and particularly relates to a full-automatic two-dimensional wire bending forming machine. The full-automatic two-dimensionalwire bending forming machine comprises a machine panel, wherein hollowed-out parts for placing fence wires are arranged on the middle part of the machine panel; double-sided shaft extension devices which extend forwards into the hollowed-out parts are arranged on the middle parts of the front edges of the hollowed-out parts; the machine panel is symmetrically arranged with the double-sided shaftextension devices serving as a panel structure on both sides of a middle shaft; and front wire bending devices which fold a wire space are arranged on the hollowed-out parts on both sides of the double-sided shaft extension devices. Wire bending shaft cores and wire bending rotating shafts which move around the wire bending shaft cores are arranged on the wire bending station sides, close to the machine panel, of the front wire bending devices. Rear wire bending devices which bend wires inwards are separately arranged at corners of the two sides and the bottom edge of the hollow parts, and wire bending die cores and wire bending rocker arms which move around the wire bending die cores are arranged on the wire bending station sides of the rear wire bending devices. The full-automatic two-dimensional wire bending forming machine has compact structure, high automation level and high forming quality, is beneficial to improving the processing technology of baskets, and brings remarkable economic benefits.

Owner:徐州奔蓝机械科技有限公司

Polisher for workpiece flange burrs and polishing process thereof

ActiveCN106272019ALess investmentReduce manufacturing costEdge grinding machinesGrinding carriagesEngineeringFlange

The invention discloses a polisher for workpiece flange burrs and a polishing process thereof and belongs to the technical field of a polishing device. The polisher for workpiece flange burrs, disclosed by the invention, comprises a bracket, a driving mechanism, a chassis and a self-polishing box, wherein the bracket has two plate structures vertically fixed on the chassis; the self-polishing box is erected in the middle of the bracket through a rotating shaft and is rotatably connected with the bracket; and the driving mechanism is used for supplying rotating power to the rotating shaft of the self-polishing box. The polisher can polish respective flanges through the mutual polishing of the workpieces; the irregularity of different workpieces after the self-polishing box is rotated at a specific rotating speed on the position and posture of the self-polishing box is fully utilized to correctly and comprehensively polish the workpiece flanges; and special polishing accessories are not needed, so that the purposes of low investment, low production cost and good polishing effect can be achieved.

Owner:ANHUI MA STEEL INTELLIGENT STEREOSCOPIC PARKING EQUIP CO LTD +1

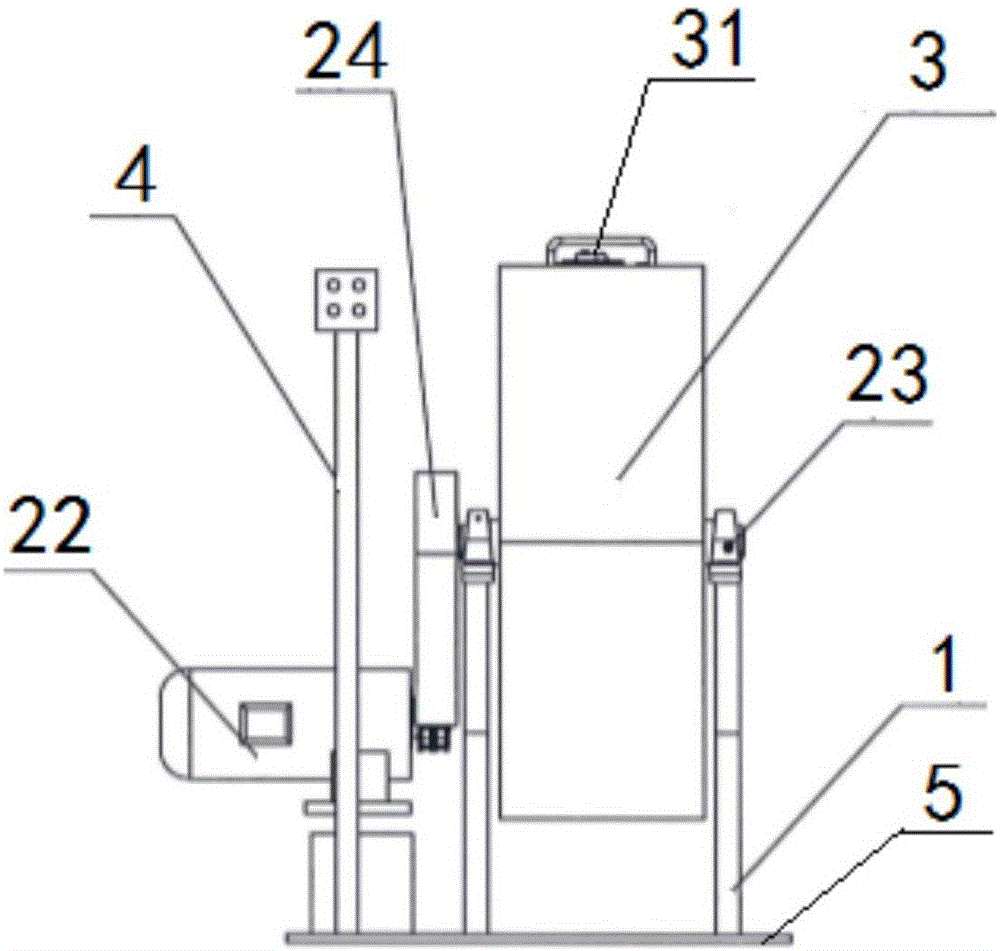

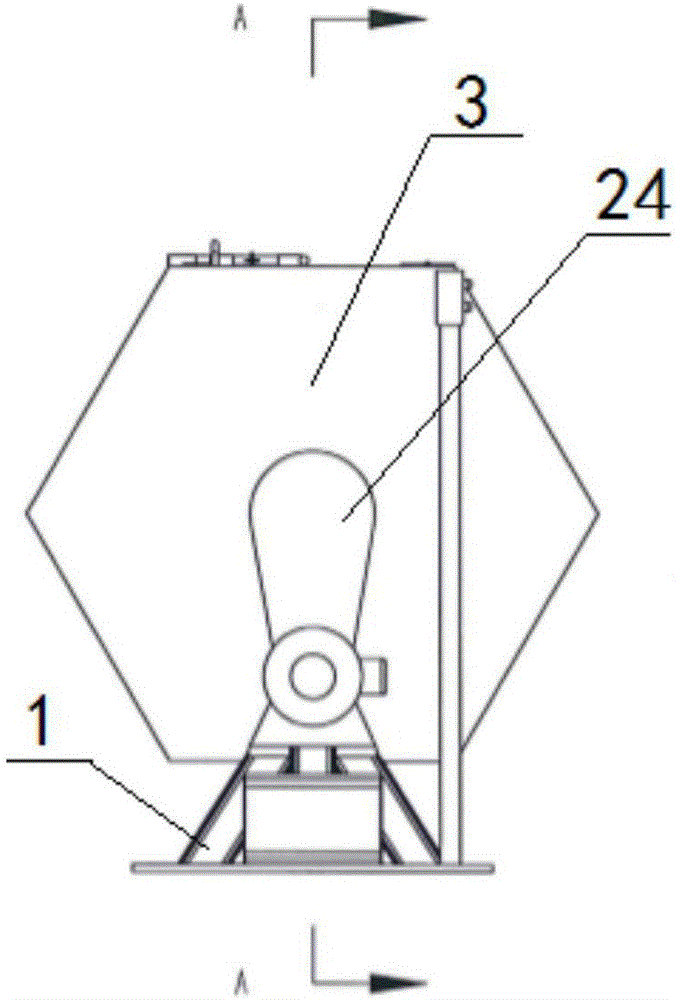

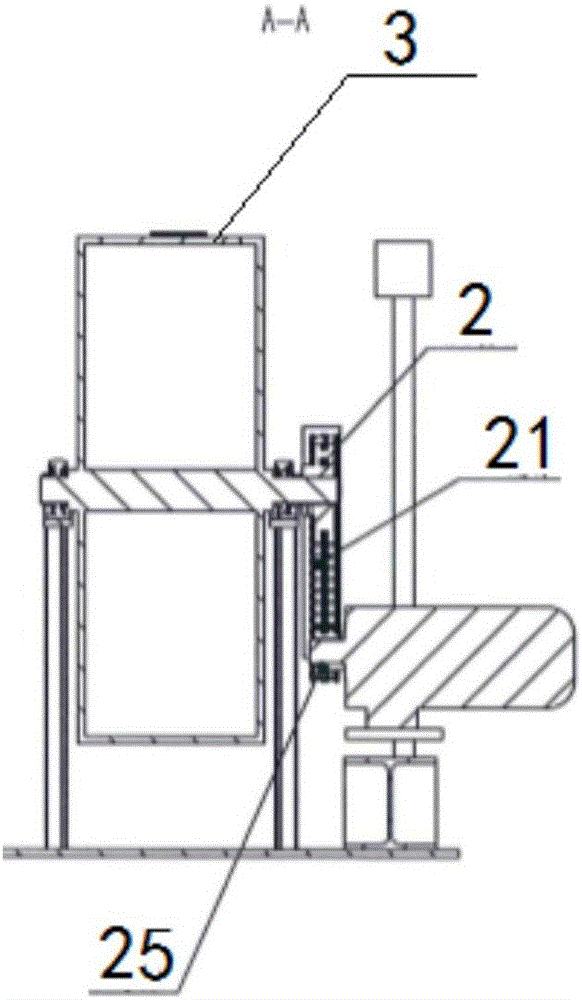

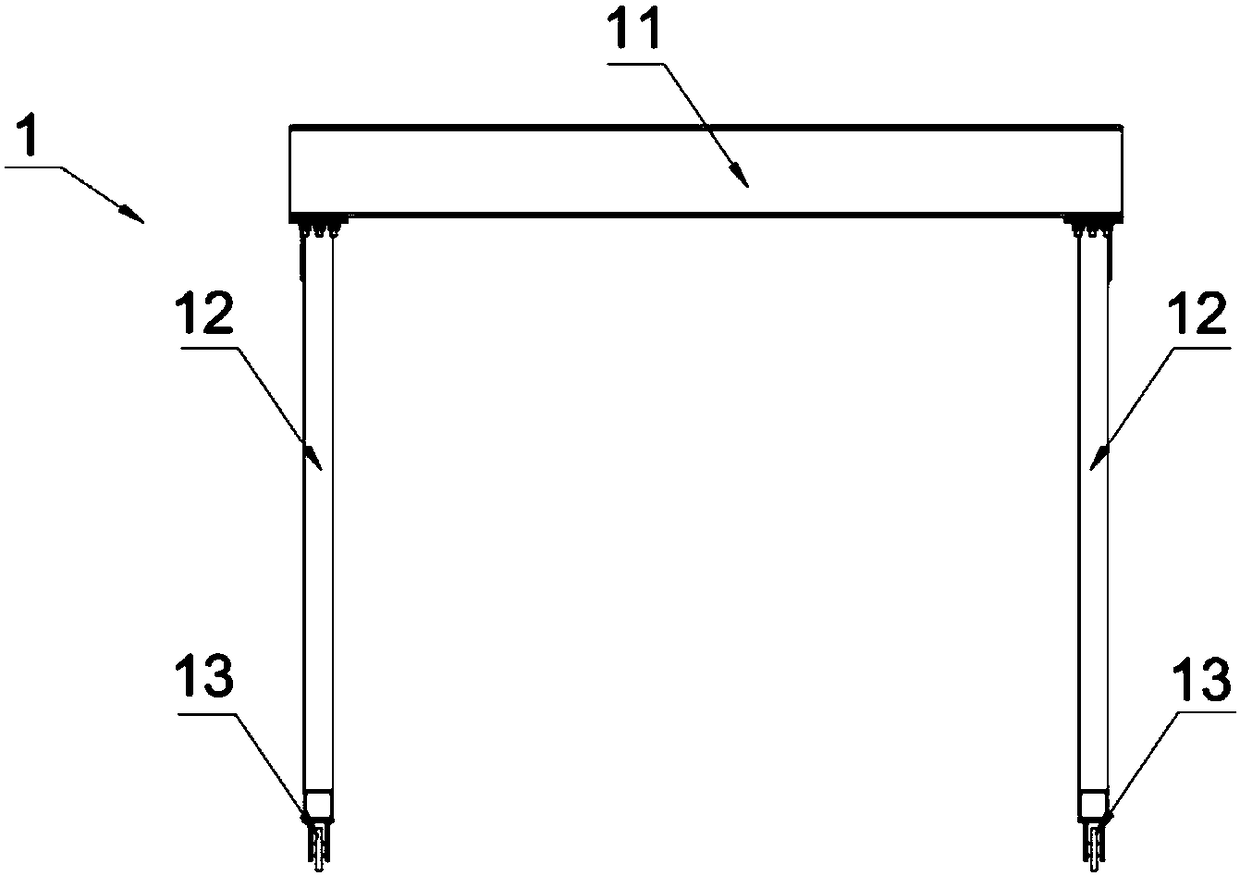

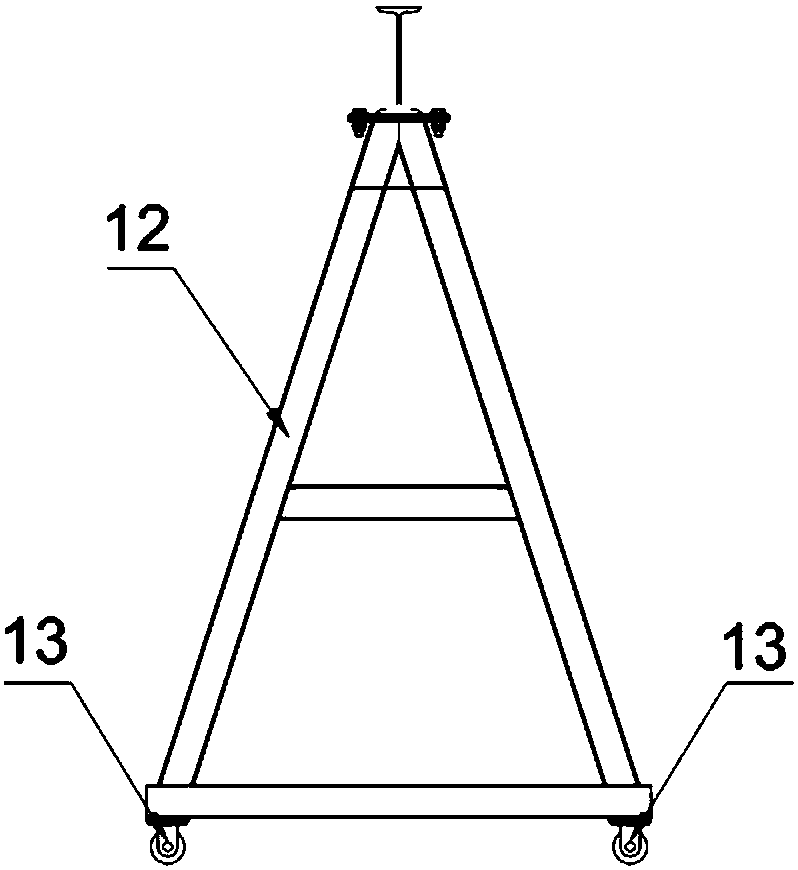

Mounting method and mounting tool for ship side large window

InactiveCN108581920AImprove support strengthImprove stabilityWork holdersMetal-working hand toolsEngineeringAutomation

The invention relates to the technical field of ship equipment mounting, and discloses a mounting method and a mounting tool for a ship side large window. According to the mounting method for the shipside large window, a lifting tool is adopted to lift the large window and move the large window to the window mounting position, the large window is transferred to a window installing tool, the window installing tool moves the large window to the designated position, and the large window is aligned; the large window is arranged on the side. According to the mounting method, through the lifting tool and the window installing tool, the large window with the large size is mounted on the side, work efficiency is improved, damage to the large window can be effectively prevented, and the worker injury risks are reduced; the mounting tool used for the ship side large window comprises the lifting tool and the window installing tool, the lifting tool is used for lifting and moving the large window, the window installing tool is used for moving the large window to the designated position, the large window is aligned, mounting is convenient, the automation degree is high, and work efficiency isimproved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Wire forming machine of portal frame structure

InactiveCN109500294AReduce the movement of station adjustmentGuarantee high efficiencyProduction lineHigh volume manufacturing

The invention belongs to the technical field of wire rolling equipment, in particular to a wire forming machine of a portal frame structure. The wire forming machine comprises a rack, an operation panel, a driving part and a control part, wherein the operation panel, the driving part and the control part are installed on the rack, and a wire adjusting mechanism which is used for straightening andflattening a coiled wire is arranged on one side of the operation panel; a wire guide mechanism which is used for conveying the wire is installed on the wire outlet end of the wire adjusting mechanismand is located on the operation panel; a rolling mechanism which is used for pressing and forming the wire is installed on the wire outlet end of the wire guide mechanism and is located on the operation panel; and a wire cutting mechanism which is used for cutting the wire at equal lengths is installed between the rolling mechanism and the wire guide mechanism and is located on the rack. The wireforming machine has the advantages of high continuity, the reasonable structure, convenience in operation and high safety factor and is favorable for mass production of enterprises, a neutral position can be avoided in a production process, and high efficiency of a production line is guaranteed.

Owner:徐州奔蓝机械科技有限公司

Butt welding all-in-one machine with automatic straightening and frame bending forming function

The invention belongs to the technical field of wire rolling equipment, in particular to a butt welding all-in-one machine with the automatic straightening and frame bending forming function. The machine comprises a machine frame. A wire adjusting assembly used for pulling a wire straight and pressing the wire flat is arranged at one end of a working surface of the machine frame. A wire outlet side of the wire adjusting assembly is located on the machine frame and is provided with a wire guiding assembly, wherein the wire guiding assembly is used for conveying the wire. A left wire bending panel and a right wire bending panel are symmetrically arranged on an assembly operation platform. An upper wire bending assembly used for carrying out inward 90-degree rolling on the wire sent out by the wire guiding assembly is arranged at the upper end of each of the two wire bending panels, and a lower wire bending assembly used for carrying out 90-degree rolling on the wire processed by the corresponding upper wire bending assembly is arranged at the lower end of each of the two wire bending panels. With the butt welding all-in-one machine with the automatic straightening and frame bending forming function, the efficiency of processing and production is improved, and it is guaranteed that operation is convenient and safe to carry out; and the machine is reasonable in structure, high in automation level, good in forming quality, and beneficial for improving the processing technology of rectangular frames, and thereby bringing significant economical benefits.

Owner:徐州奔蓝机械科技有限公司

U-shaped wire forming machine

InactiveCN110216215ARealize automated productionImprove processing technologyWire rodHigh volume manufacturing

The invention belongs to the technical field of wire machining equipment, and particularly relates to a U-shaped wire forming machine. The U-shaped wire forming machine comprises a machine frame whichis provided with a machining plate perpendicularly fixed to a machine frame transverse beam; the middle of the front surface of the machining plate is provided with a beveling mold core; material supporting devices symmetrical in structure are arranged in the positions, on the two sides of the beveling mold core, of the surface of the machining plate; the top of the machining plate is provided with a wire bending device which is used for cooperating with the beveling mold core to complete wire rolling; and the front surface of the machining plate is provided with a feeding assembly used for feeding wires to the beveling mold core and the material supporting device. According to the U-shaped wire forming machine, by arranging the feeding assembly and a discharging assembly which cooperatewith the machine for production on the machine frame, the occupational injury risk in the production process can be reduced while the work loads of workers are decreased, and operation convenience andsafety are ensured; and the U-shaped wire forming machine is reasonable in structure, batch production is facilitated through automatic procedures, the forming quality is high, the U-shaped wire machining technology is improved advantageously, and remarkable economic benefits are brought.

Owner:徐州奔蓝机械科技有限公司

Artificial board integrated forming equipment and manufacturing process thereof

ActiveCN113334655AIncrease profitReduce pollutionSolid waste managementManufacturing technologyProcess engineering

The invention provides artificial board integrated forming equipment and a manufacturing process thereof. The artificial board integrated forming equipment comprises a pouring platform, a second backup plate is arranged above the pouring platform, a bottom plate is arranged on one side of the second backup plate at intervals, and a first shaping area is formed between the bottom plate and the second backup plate; and the upper portion of the bottom plate and the first shaping area are used for pouring and forming an artificial board product. According to the artificial board integrated forming equipment and the manufacturing process thereof, a traditional flat plate type crawler belt forming assembly line platform is improved into a process modeling type crawler belt forming assembly line platform, technical work of follow-up processing of artificial stone plates (solid plane materials) is continuously completed at a time in the plate production process, procedures are reduced, work efficiency is improved, manpower and material resource cost is reduced, post-processing dust and sewage pollution is reduced, and enterprise profits are improved.

Owner:江苏千尊达新型建材有限公司

Automatic feeding and discharging method for welding wire spool

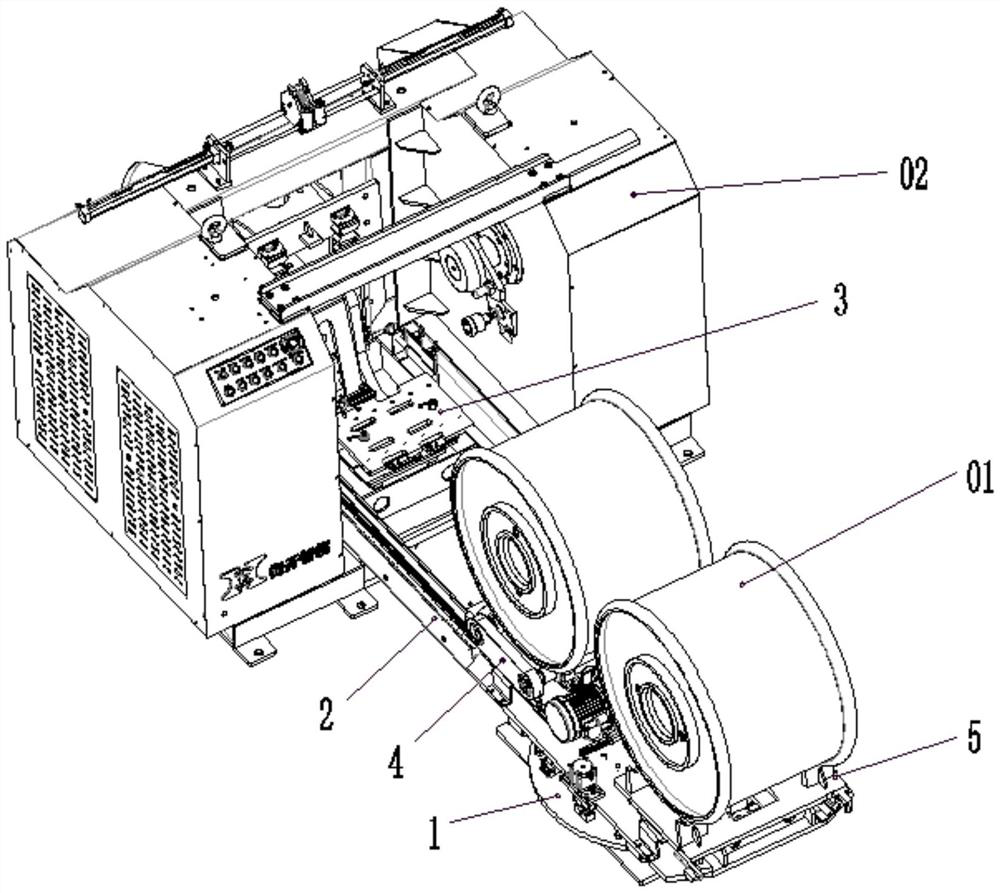

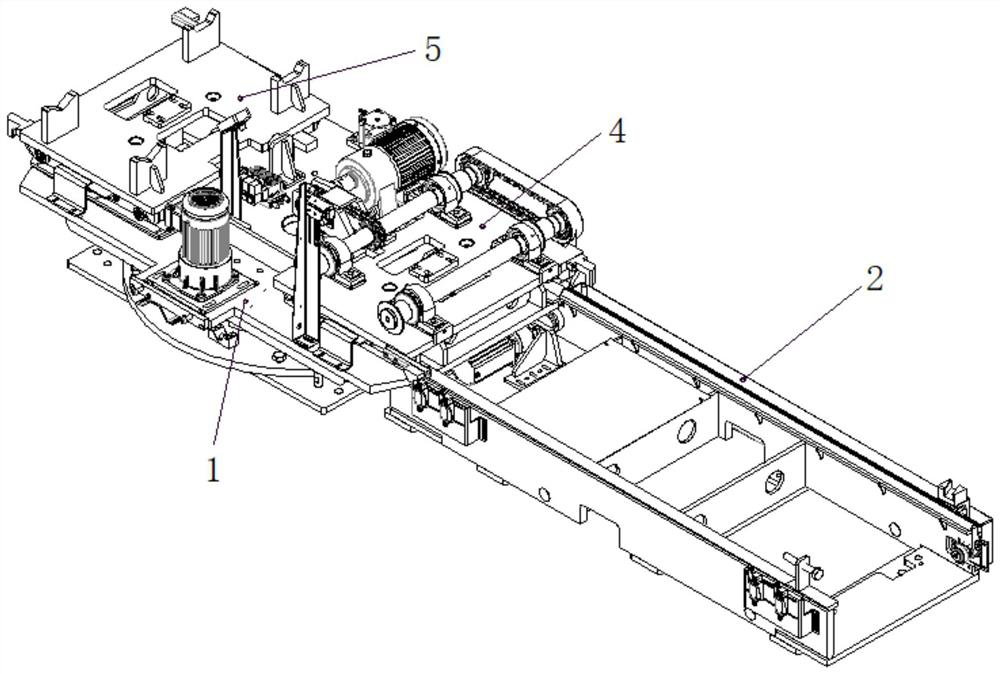

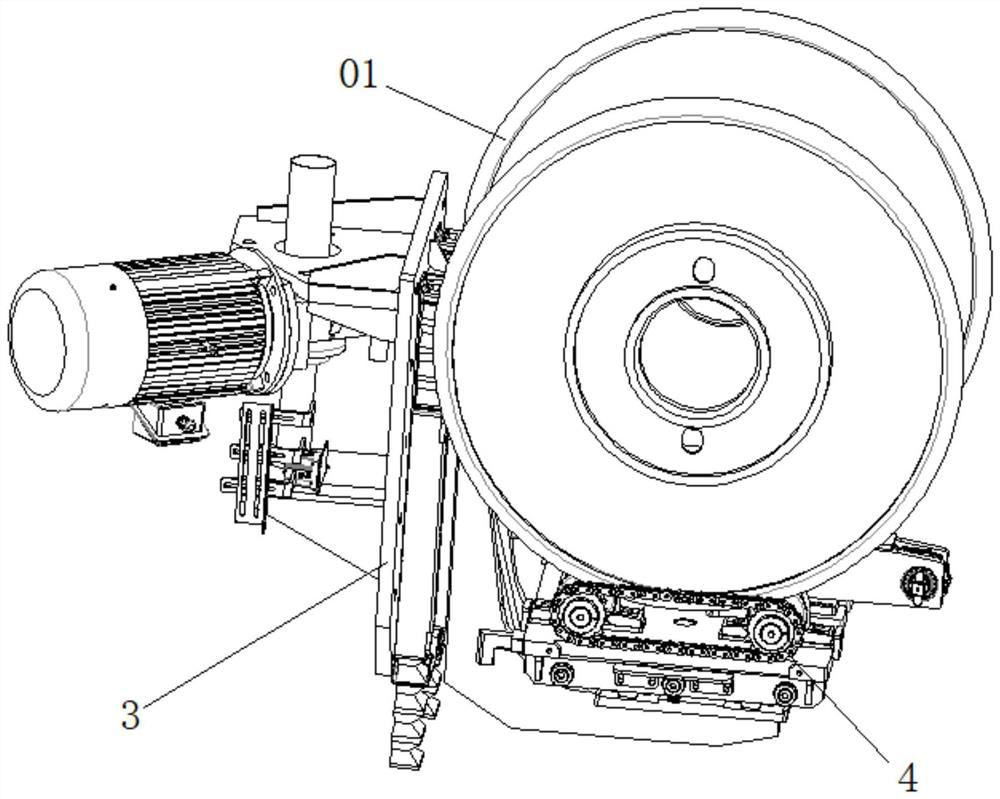

PendingCN114212510AIncrease productivityReduce labor costsControl devices for conveyorsMechanical conveyorsPhysicsSlewing bearing

According to the automatic feeding and discharging method for the welding wire spools, automatic feeding and discharging equipment for the welding wire spools is adopted in the automatic feeding and discharging method for the welding wire spools, and the automatic feeding and discharging equipment for the welding wire spools comprises a double-station rotating platform, a linear transplanting platform, a lifting mechanism and a feeding carrying disc; the two ends of the linear transplanting platform are connected with the double-station rotating platform and the lifting mechanism correspondingly. The double-station rotating platform comprises a rotating platform base, a slewing bearing and a rotating platform panel; the rotating platform panel is arranged above the rotating platform base through the slewing bearing; two tray carrying stations are arranged on the rotating platform panel, the two tray carrying stations are in central symmetry, and each tray carrying station comprises a tray carrying positioning mechanism and a rotating platform tray carrying rail; a rotating motor is further arranged on the rotating platform panel; the linear transplanting platform comprises a driving stepping motor, a transmission chain, a carrying disc hook seat and two parallel rails; the drive stepping motor drives the loading disc hook base to drive the feeding loading disc to move along the track.

Owner:长沙衡开智能科技有限公司

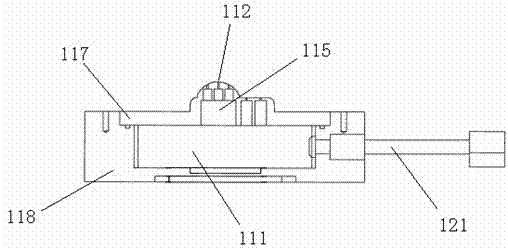

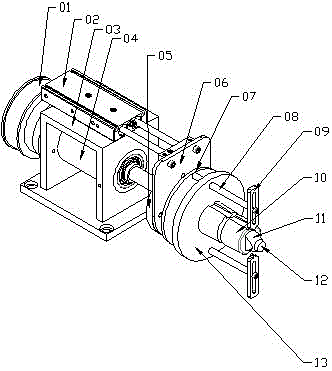

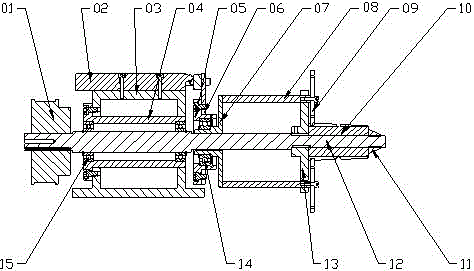

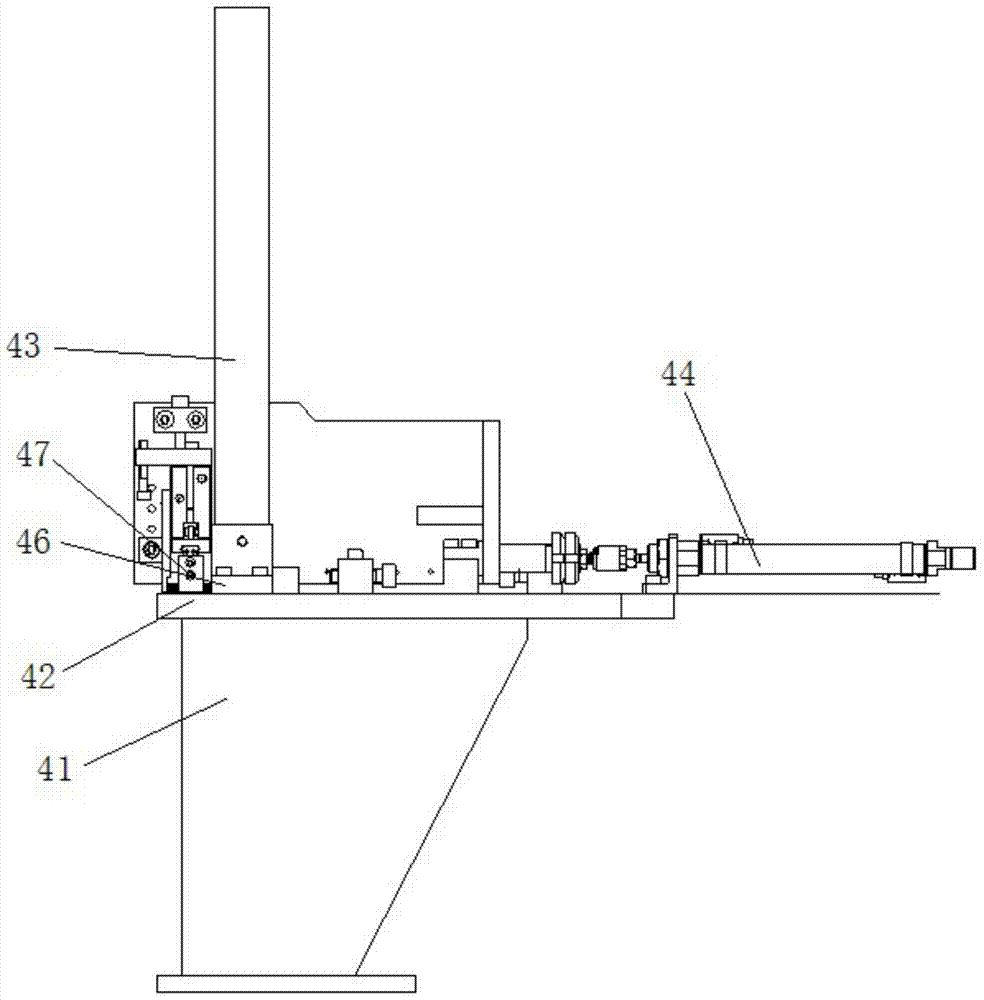

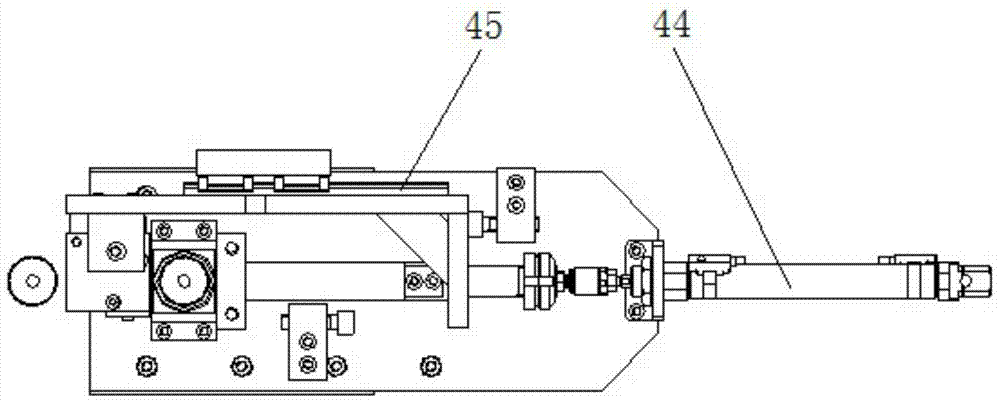

A rubber and plastic pipe cutting head tightening and ejecting device

ActiveCN105034066BReduce labor intensityIncrease productivityMetal working apparatusControl systemClassical mechanics

The invention discloses a rubber and plastic pipe cutting head ejecting-in / out device. The rubber and plastic pipe cutting head ejecting-in / out device comprises a nut, a mold, a shaft pushing frame, a pushing plate, a slide shaft, a guide shaft, a bearing, a bearing base, a cylinder, a base frame, a synchronous wheel, a proximity switch base, a proximity switch, a base plate, a bearing finger arm, a pushing finger, an induction piece and a control system, wherein the synchronous wheel is fastened on the guide shaft; the bearing coats the guide shaft, and is connected with the base frame through the bearing base; the slide shaft is inserted in a hole of the guide shaft to perform the reciprocating slide; the mold coats the slide shaft, and is locked by the nut; the slide shaft is connected with a piston cylinder of the cylinder through the shaft pushing frame and the pushing plate; the cylinder is fixed on the base plate; the two ends of the base plate are respectively fastened with the base frame and the bearing finger arm; the pushing finger is fixed on the bearing finger arm, and performs the reciprocating slide in a slide finger groove of the mold; and the proximity switch is fixed on the shaft pushing frame through the proximity switch base.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

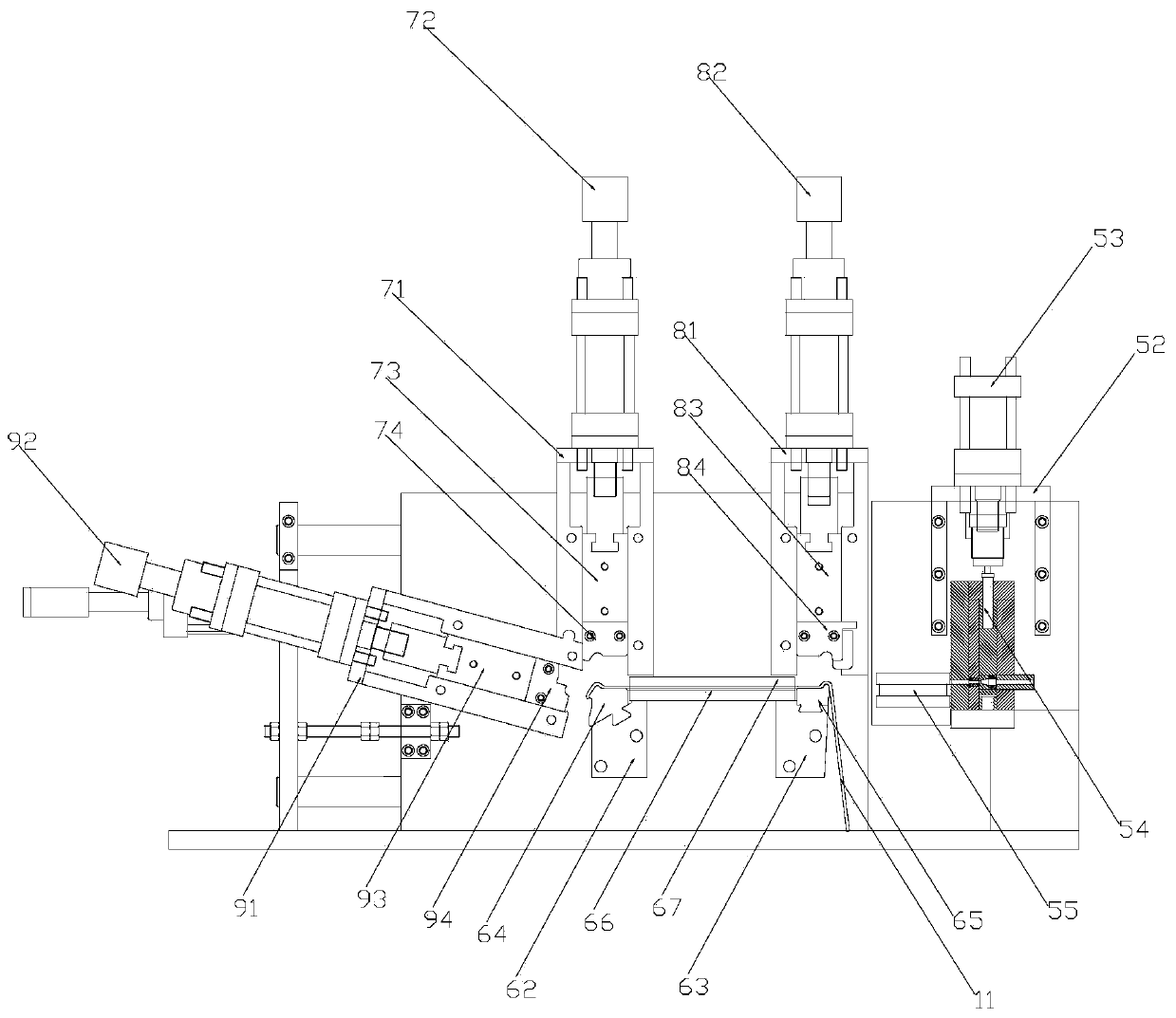

Full-automatic wire rod double-end oblique angle cutting-off machine

The invention belongs to the technical field of wire rod processing equipment, and particularly relates to a full-automatic wire rod double-end oblique angle cutting-off machine which comprises a rackand a cutting machine vertical plate perpendicularly arranged on the rack. A left guide rail and a right guide rail symmetrical left and right are arranged on the front surface of the cutting machinevertical plate; a cutting-off die holder for placing a processed inclined strut line is arranged at the position, located on the front surface of the cutting machine vertical plate, between the leftguide rail and the right guide rail; a vertical sliding block moving up and down between the left guide rail and the right guide rail is arranged at the movable end of a cutting machine oil cylinder;a pressing assembly for fixing the inclined strut line on the cutting-off die holder and an oblique angle cutter for cutting feet are arranged on the vertical sliding block; and a loading assembly fixed onto the left guide rail and the right guide rail is arranged on the front surface of the cutting machine vertical plate. According to the full-automatic wire rod double-end oblique angle cutting-off machine provided by the invention, the workload is reduced, meanwhile, the work injury risk in the production process can be reduced, the convenience and the safety in operation are ensured, and the full-automatic wire rod double-end oblique angle cutting-off machine is compact in structure, high in automation level, high in molding quality, conducive to improving an inclined strut line processing process, and capable of bringing a remarkable economic benefit.

Owner:徐州奔蓝机械科技有限公司

Full-automatic forming machine for L-shaped line

The invention belongs to the technical field of wire rod rolling equipment, in particular to a full-automatic forming machine for an L-shaped line. The full-automatic forming machine for the L-shapedline comprises a rack, wherein a line adjusting mechanism for straightening and flattening a wire rod is arranged at one end of a working surface of the rack; a line guiding mechanism for conveying the wire rod is arranged at the position, on the working surface of the rack, at a line outlet side of the line adjusting mechanism; a line cutting vertical plate and a rolling vertical plate are sequentially arranged at the positions, on the working surface of the rack, at a line outlet side of the line guiding mechanism; a line supporting assembly for placing the wire rod delivered from the line outlet side of the line guiding mechanism is arranged on the rolling vertical plate; a top angle rolling mechanism and a bottom angle rolling mechanism matched with the line supporting assembly for bending the wire rod are arranged at the positions, on the rolling vertical plate, above the line supporting assembly; and an oblique angle rolling mechanism matched with the top angle rolling mechanismso as to shrink an angle of the end part of the wire rod is arranged on the rolling vertical plate. The full-automatic forming machine for the L-shaped line provided by the invention is beneficial toimproving the production efficiency and a forming effect of the L-shaped line, reasonable in structure, high in automation level, stable in forming quality, and good for the production benefit of a storage basket processing market.

Owner:徐州奔蓝机械科技有限公司

Fully automatic single punching manipulator

ActiveCN104070558BGet rid of influenceLabor savingMetal working apparatusPunch pressWork related injuries

Owner:SHENZHEN MAKEN M & E

Ink supply device, pad printing machine comprising same and control method thereof

InactiveCN102632702BIngenious structureEasy to controlTransfer printingPrinting press partsPad printingEngineering

The invention provides an ink supply device, a pad printing machine comprising the same and a method for controlling the ink supply device, which are used for pad printing operation for coating surfaces of plastic toys and the like, realize coating of the toys with large change of curves, can overcome shortcomings of traditional pad printing equipment, and improve production efficiency and guarantee coating quality. The ink supply device comprises an ink supply box with an internal cavity, an ink opening communicated with the cavity is arranged on the top of the ink supply box, and the ink supply device is further provided with a squeezing device used for squeezing out ink in the cavity to the ink opening. The pad printing machine with the ink supply device comprises the ink supply device, a pad printing head component, a pad printing head transmission component, a plastic part fixing component, a control unit and a framework, the pad printing head component is used for printing a plastic part to be printed, the pad printing head transmission component is used for moving the pad printing head component, the plastic part to be printed is fixed by the aid of the plastic part fixing component, the ink supply device, the plastic part fixing component, the pad printing head transmission component and the control unit are mounted on the framework, and the pad printing component is mounted on the pad printing head transmission component.

Owner:中扩实业集团有限公司

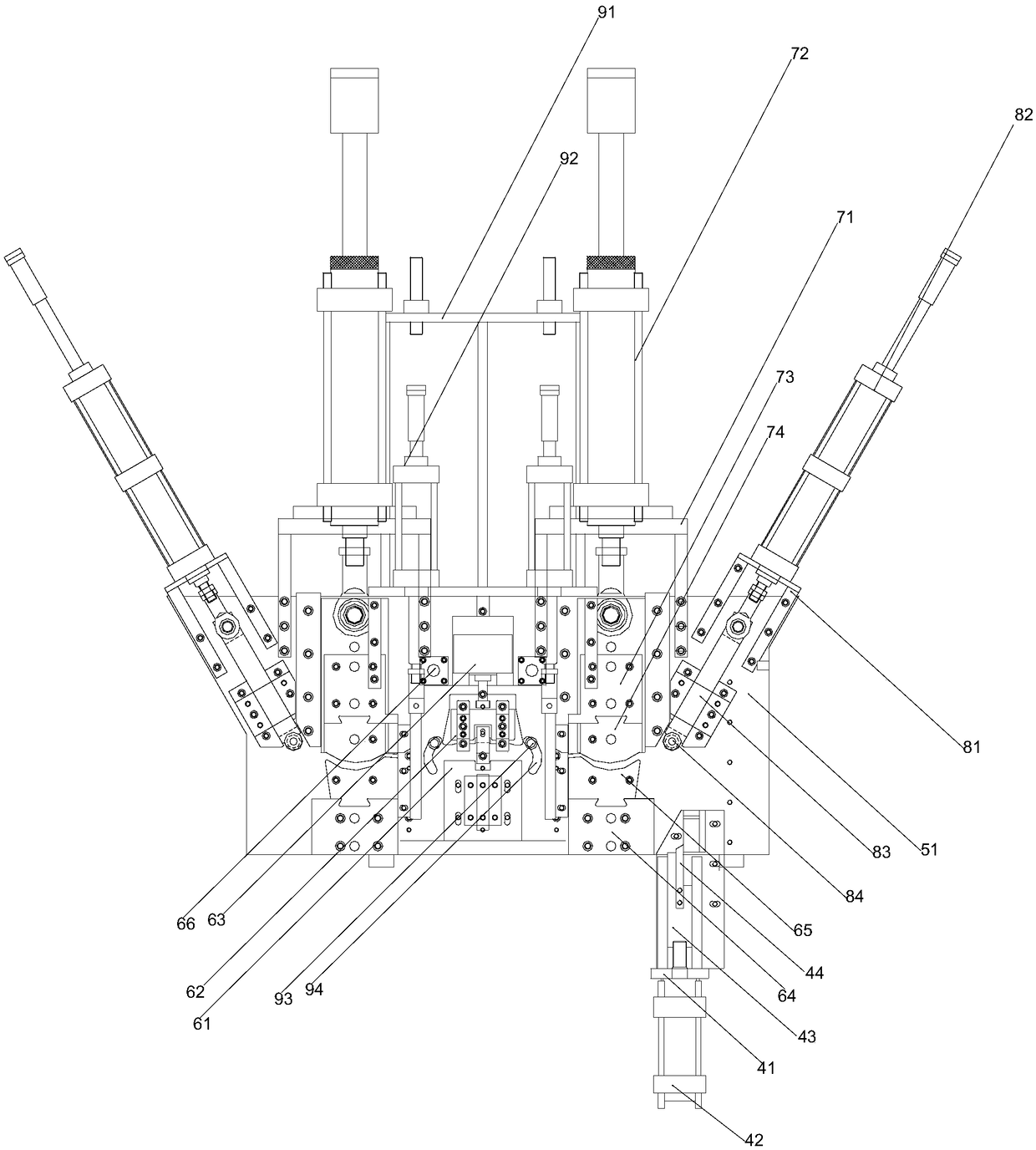

Automatic forming machine for supporting frame

InactiveCN110125293ARealize automated productionIncrease productivityWire articlesWire rodClothes hanger

The invention belongs to the technical field of wire rolling equipment, and particularly relates to an automatic forming machine for a supporting frame. The automatic forming machine comprises a rack,a wire adjusting mechanism for straightening and flattening a wire is arranged at one end of the work face of the rack, and a wire guide mechanism for conveying the wire is mounted at the position, on the work face of the rack, of the wire-out side of the wire adjusting mechanism. A vertical operation table is mounted at the position, on the work face of the rack, of the wire-out side of the wireguide mechanism, a wire supporting seat for containing the wire conveyed out by the wire-out side of the wire guide mechanism is arranged in the middle of the operation table, a compressing mechanismfor fixing the wire in cooperation with the wire supporting seat is mounted at the position, above the wire supporting seat, of the operation table, rolling mechanisms for rolling the wire are mounted at the positions, located on the operation table, of the two sides of the compressing mechanism, and hook rolling mechanisms for press-bending the end of the wire are mounted at the positions, located on the operation table, of the two sides of the rolling mechanisms. According to the automatic forming machine, the production efficiency and forming effect of the supporting frame are improved, the structure is reasonable, the automation level is high, the forming quality is high, and the automatic forming machine is beneficial to being popularized and applied in the clothes hanger processingmarket.

Owner:徐州奔蓝机械科技有限公司

SRB automatic tin welding machine

InactiveCN105904048AAvoid harmSimple structural designWelding/soldering/cutting articlesMetal working apparatusEngineeringRosin

The invention discloses a SRB automatic tin welding machine. The SRB automatic tin welding machine comprises a stand, a control panel, a tray carrying device, a product feeding mechanism, a feeding rail, a rosin dipping waiting area, a rosin dipping mechanism, a product transfer station, a tin welding mechanism, an automatic tin feeding device, a product discharge mechanism and a carrying platform; the control panel is arranged in front of the tabletop of the stand; the tray carrying device, the feeding rail, the product feeding mechanism, the rosin dipping waiting area, the rosin dipping mechanism, the product transfer station, the tin welding mechanism and the product discharge mechanism are arranged on the tabletop of the stand from right to left; the carrying platform is arranged above the tray carrying device; an empty tray placing area, a product taking area and a full tray placing area are arranged on the carrying platform from front to back; and the automatic tin feeding device is arranged on the side surface of a welding gun of the tin welding mechanism. The SRB automatic tin welding machine is simple in structural design, mainly can reduce the labor cost, reduces the risk of industrial injury, prevents the harm to personal health in tin welding, enables assembled products to be more standard, and improves the production efficiency and the product quality.

Owner:MINGGUANG SANYOU ELECTRONICS

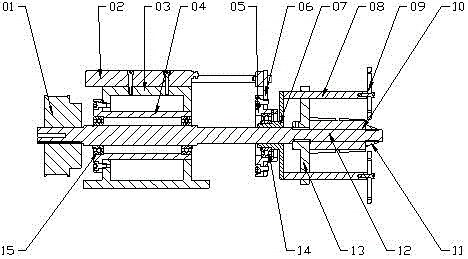

Rubber tube scrap edge unloading device

InactiveCN105034065AReduce labor intensityReduce the risk of work-related injuriesMetal working apparatusControl systemDrive shaft

The invention discloses a rubber tube scrap edge unloading device. The rubber tube scrap edge unloading device comprises a synchronizing wheel, an air cylinder, a seat frame, a bearing base, a movable bearing base, a pushing plate, a pushing disc, a pushing rod, a pushing finger, a supporting mould, a locking nut, a drive shaft, a supporting disc, a bearing A, a bearing B and a control system. The synchronizing wheel is arranged at one end of the drive shaft in a sleeving mode; the bearing B is arranged on the waist part of the drive shaft in the sleeving mode; the bearing base and a double-shaft air cylinder are fixed on the seat frame; the pushing disc is arranged on the waist of the drive shaft in the sleeving mode, adjacent to the seat frame, and connected with the movable bearing base; the movable bearing base is connected with the piston rod of the air cylinder; the pushing rod penetrates through a through hole in the supporting disc, and then is connected with the pushing finger; the supporting disc and the supporting mould are arranged at the other end of the drive shaft in the sleeving mode, and are fastened by nuts; and the pushing disc, the supporting disc and the supporting mould are driven by the drive shaft to rotate. According to the rubber tube scrap edge unloading device, scrap edges of the rubber tubes can be automatically unloaded, the labor intensity is relieved, the industrial injury risks are reduced, and the production efficiency is improved.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

Sand blasting machine and method for removing burrs and air marks of plastic products by using the sand blasting machine

ActiveCN106272099BReduce the risk of injuryReduce labor costsAbrasive machine appurtenancesAbrasive blasting machinesSand blastingStructural engineering

Owner:周选保

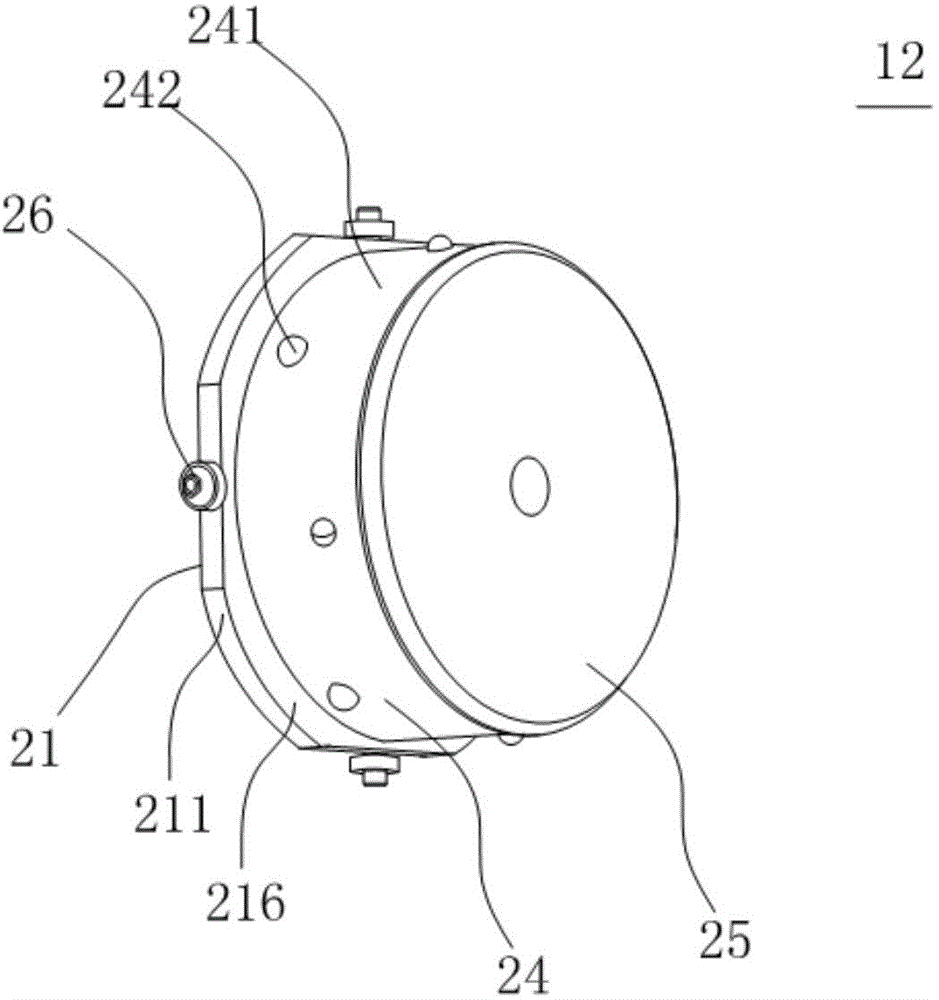

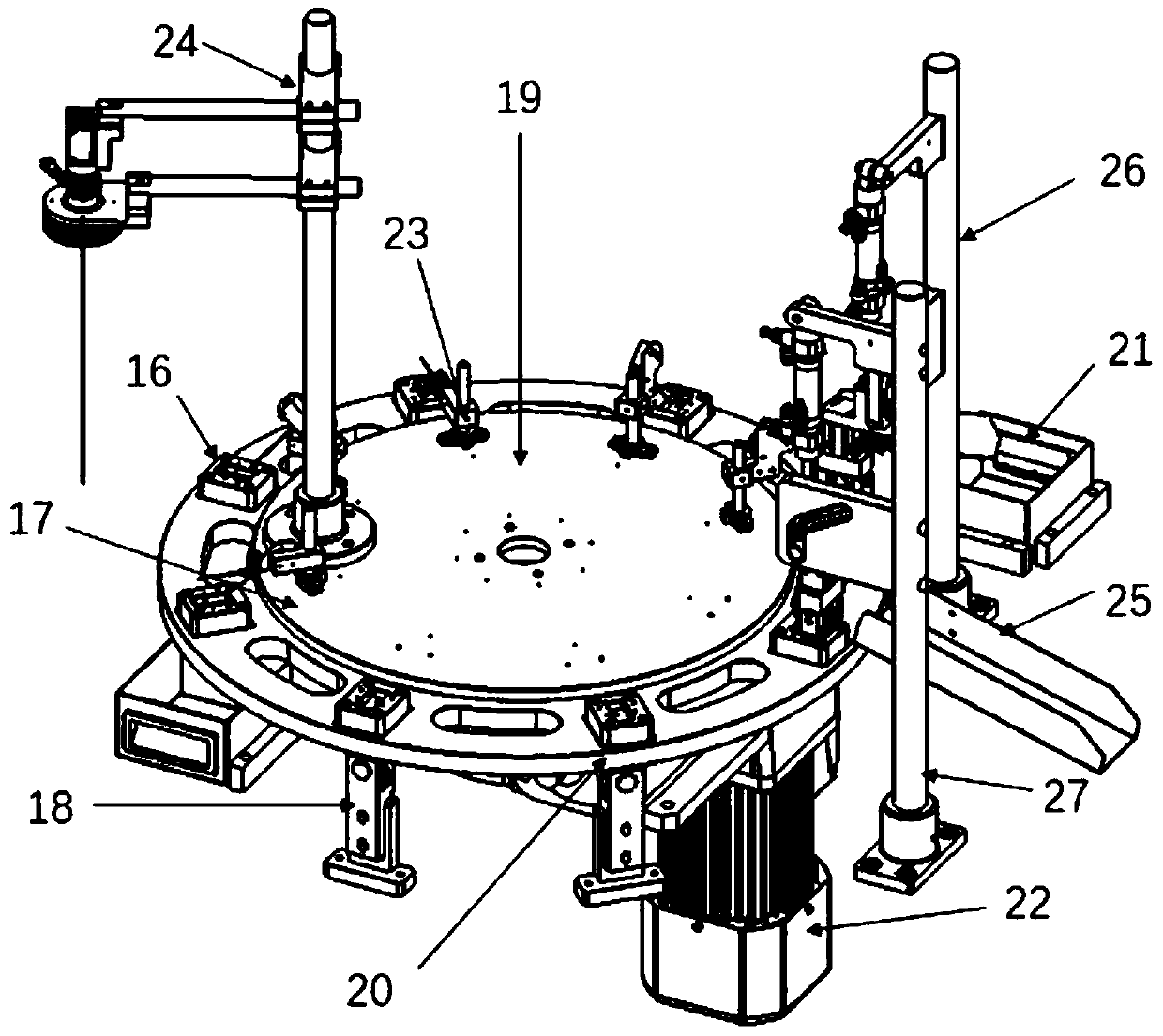

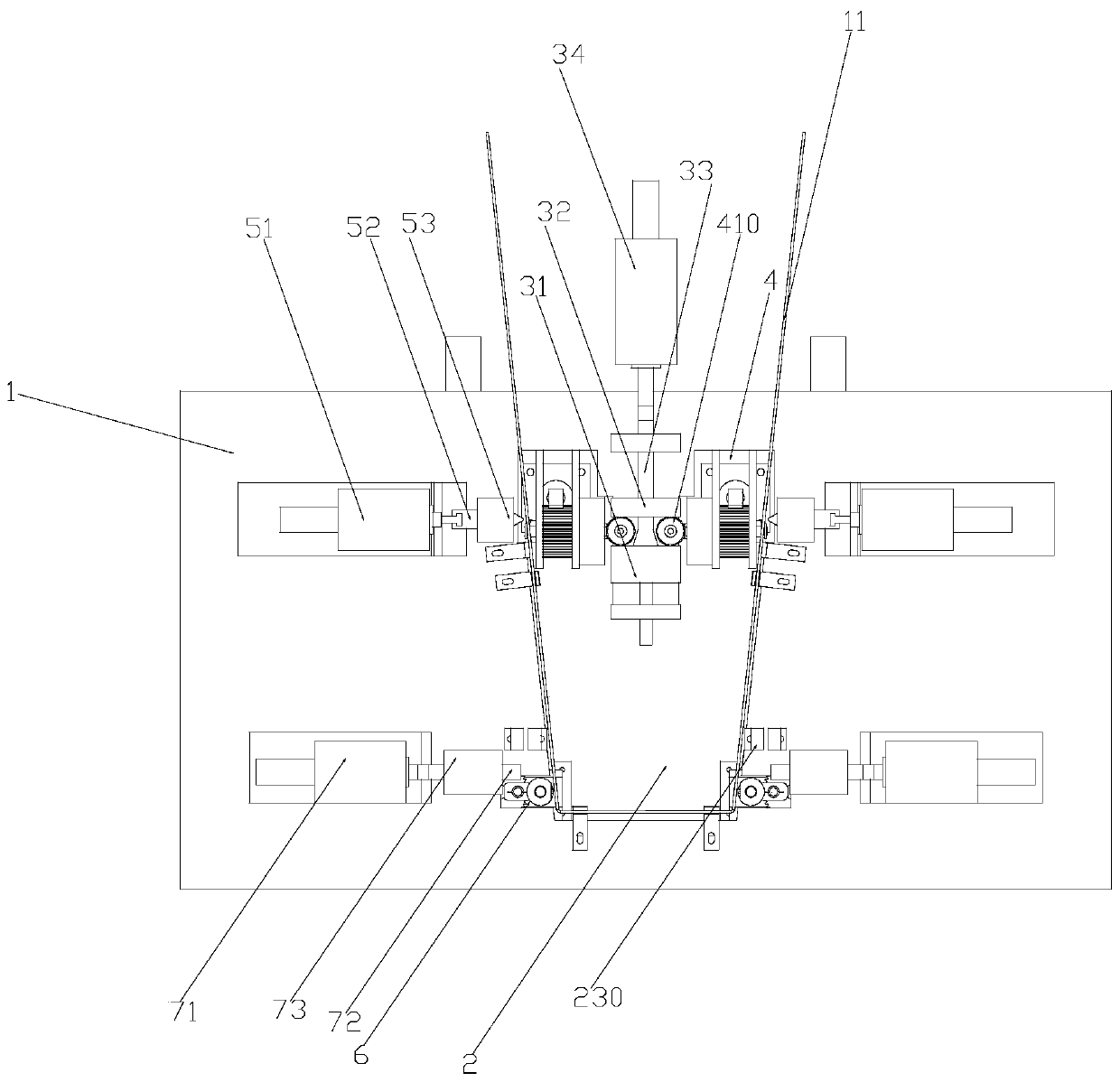

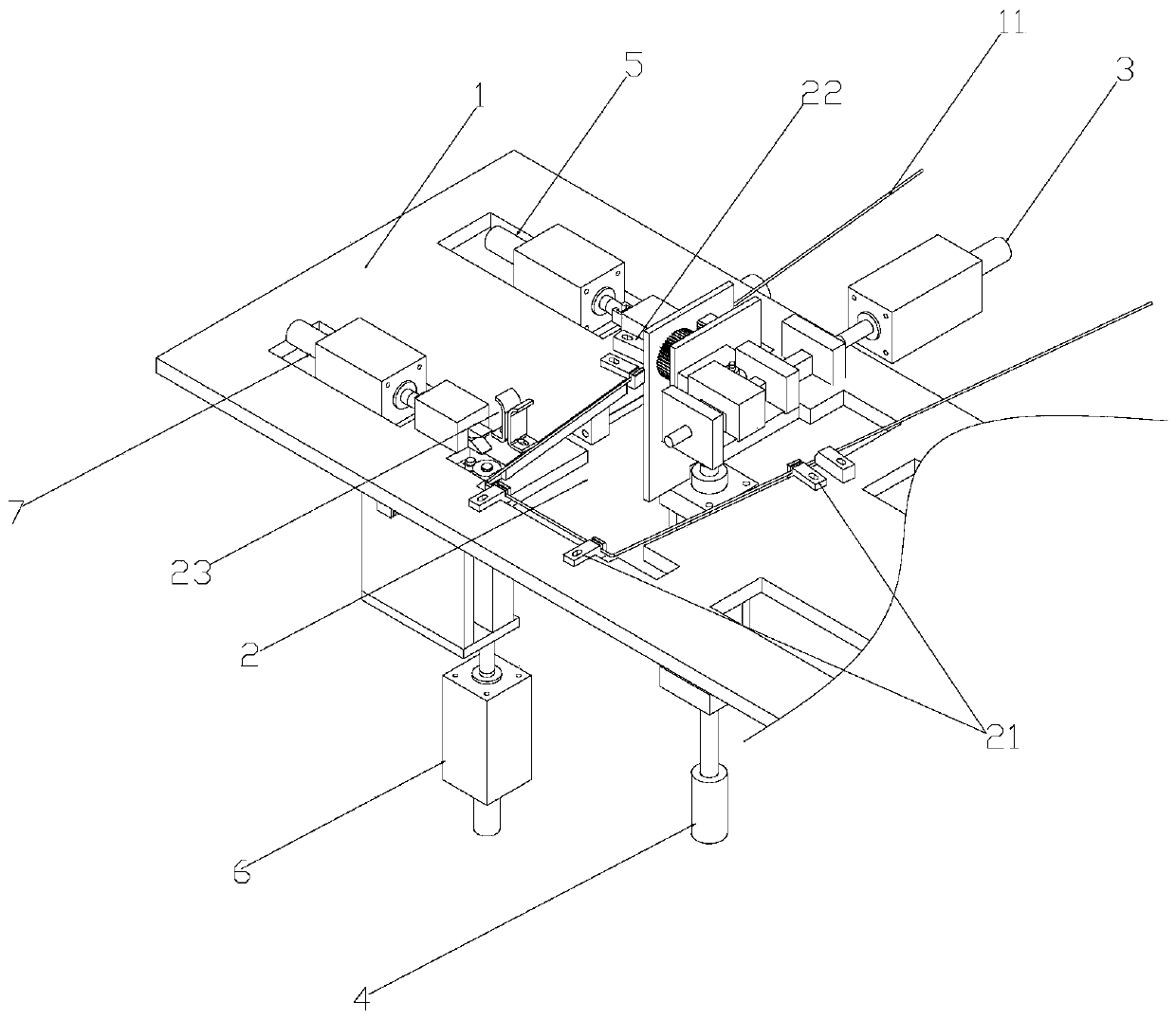

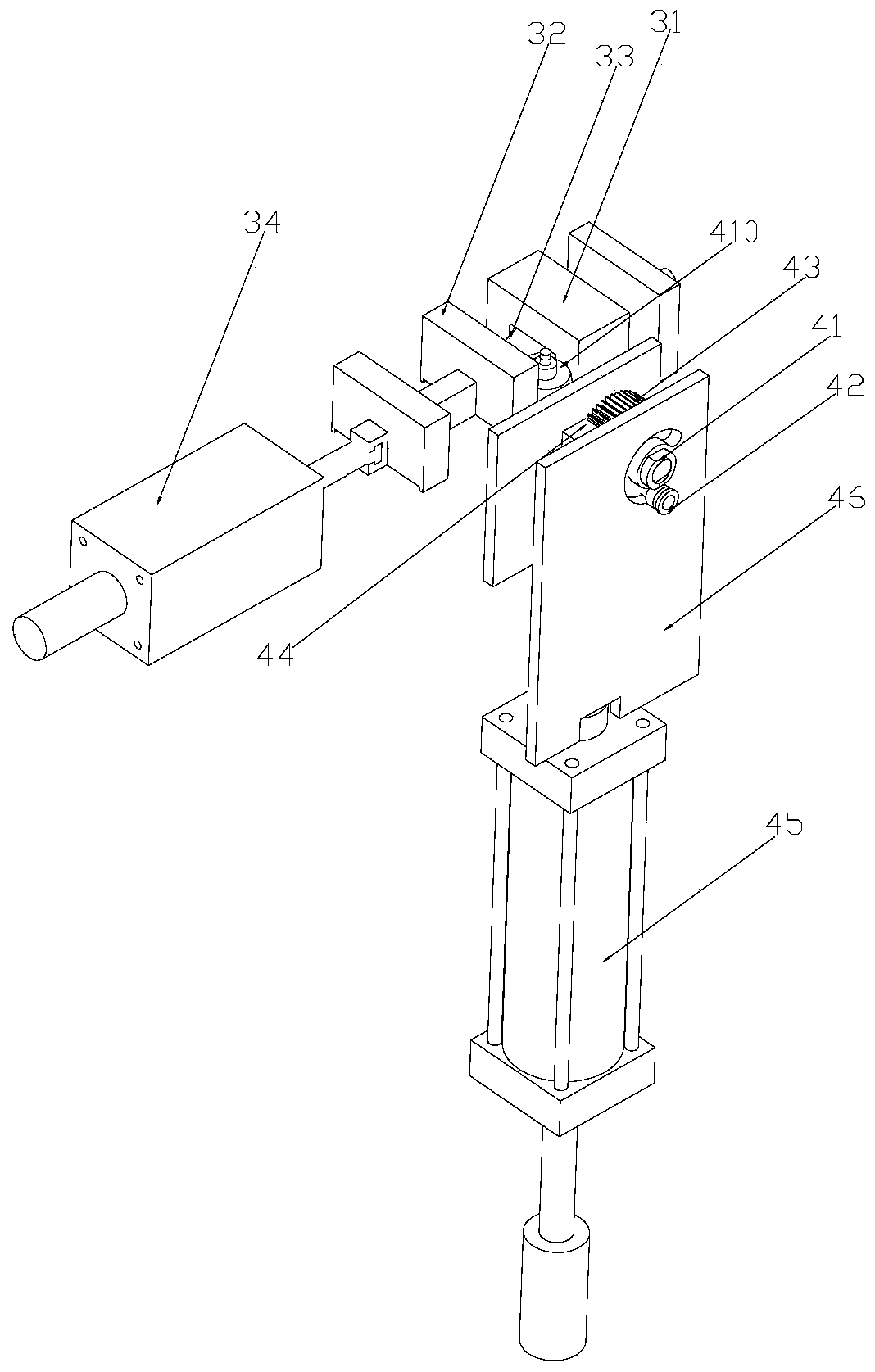

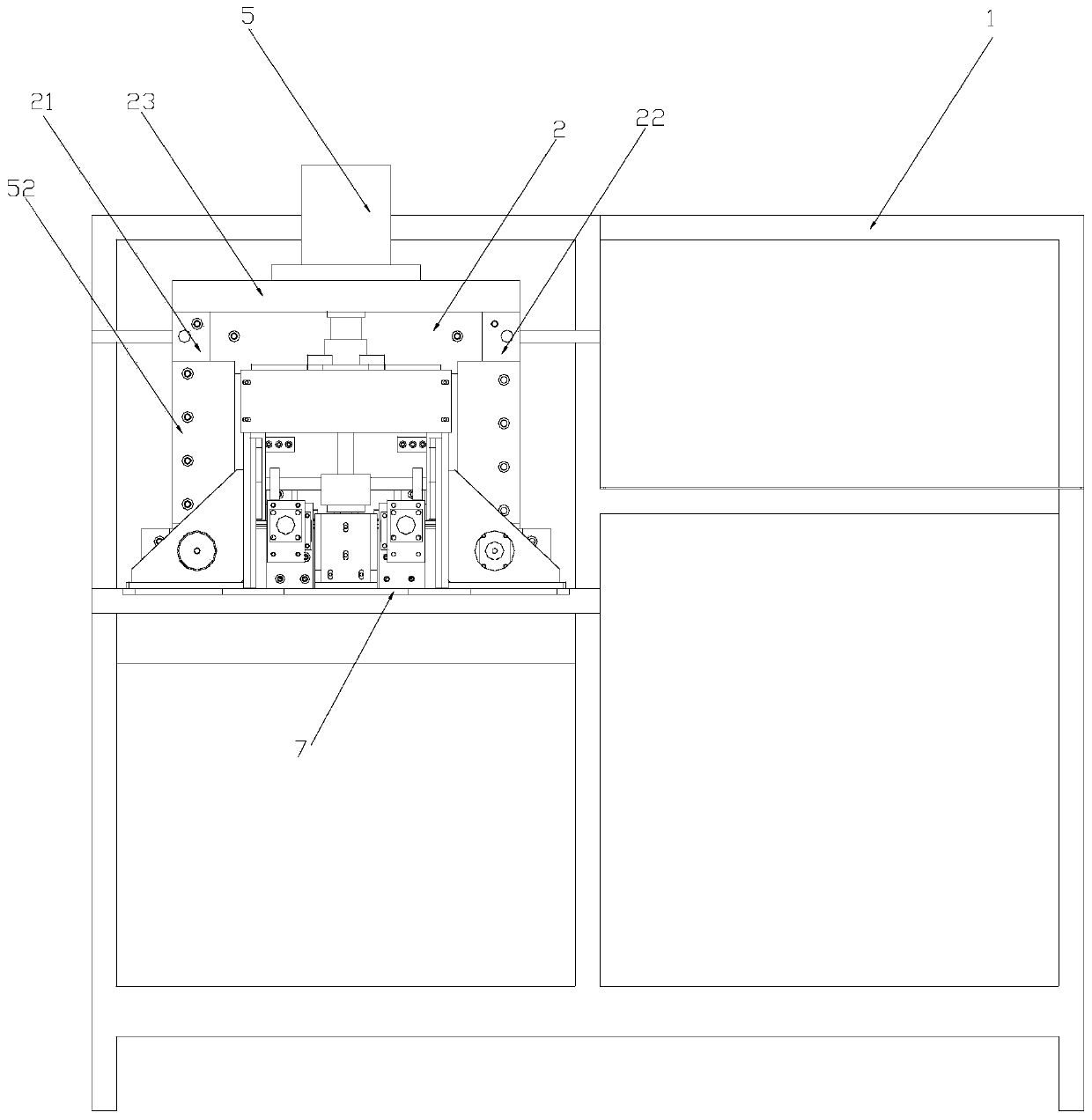

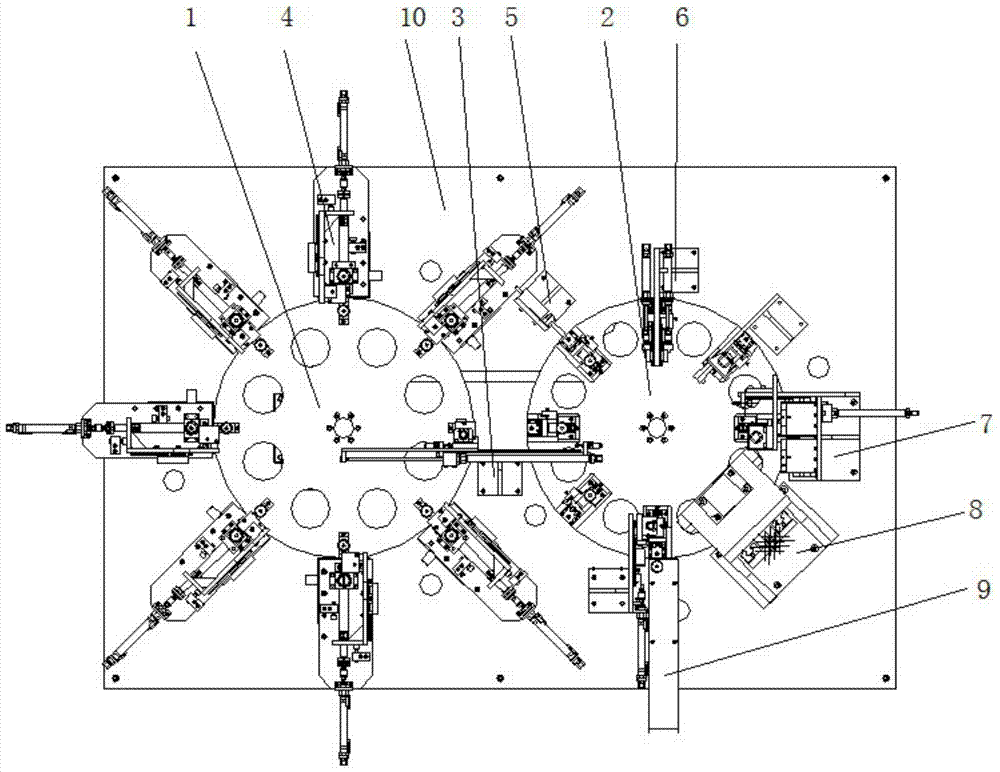

Hybrid stepper motor rotor assembly machine

ActiveCN104716793BReduce labor intensityIncrease success rateManufacturing stator/rotor bodiesHybrid typeTransmission switching

The invention discloses a hybrid stepping motor rotor assembly machine, which includes a workbench; on the workbench are distributed a rotatable rotor initial assembly disc and a rotor press-fit disc, and the two discs pass through the rotor initial assembly Exchange station transmission connection, set a number of workpiece stacking stations along the outer circumference of the rotor initial loading plate, and set up a clamp opening and closing device and a tooth-staggered station in a clockwise direction along the outer circumference of the rotor press-fitting plate , the rotating shaft preliminary installation station, the rotating shaft pressing station and the blanking station. The assembly machine of the present invention adopts automatic production and assembly, wherein only the operator needs to replenish the workpiece for the feeding device; not only the labor intensity of the workers is reduced, Reduces the risk of work-related injuries while improving assembly quality and stability.

Owner:CHANGZHOU INST OF NUMERICAL CONTROL TECH

Medium-long beam production system and medium-long beam production and manufacturing method

PendingCN112453250AHigh degree of production automationConsistent qualityMetal-working feeding devicesLoad-supporting pillarsElectric machineryMachine

The invention provides a medium-long beam production system and a medium-long beam production and manufacturing method. The medium-long beam production system comprises a feeder and a plurality of machining devices, the feeder and the machining devices are sequentially arranged in the material circulation direction, a transfer machine is further arranged between every two adjacent machining devices, the feeder comprises an unwinding motor, an unwinding roller is fixedly connected to an output shaft of the unwinding motor, and the control end of the unwinding motor, the control ends of the machining devices and the control end of the transfer machine are electrically connected with a control device through wires. The medium-long beam production and manufacturing method comprises the machining process step of adopting the medium-long beam production system. By adopting the technical scheme of the medium-long beam production system and the medium-long beam production and manufacturing method, the feeder, the machining devices and the transfer machine which are used in the medium-long beam production process are connected together through the control device, the production technological process and the production takt are controlled in a unified mode through the control device, the labor intensity of workers is relieved, the production efficiency is improved, materials are transferred through the transfer machine, and the risk of industrial injury of an operator is reduced.

Owner:ZUNYI FENGHUA ELECTROMECHANICAL FITTINGS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com