U-shaped wire forming machine

A forming machine and U-shaped technology, applied in the field of U-shaped line forming machines, can solve problems such as unstable quality, increased labor intensity, and low efficiency, and achieve the effects of reducing the risk of work-related injuries, reducing workload, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

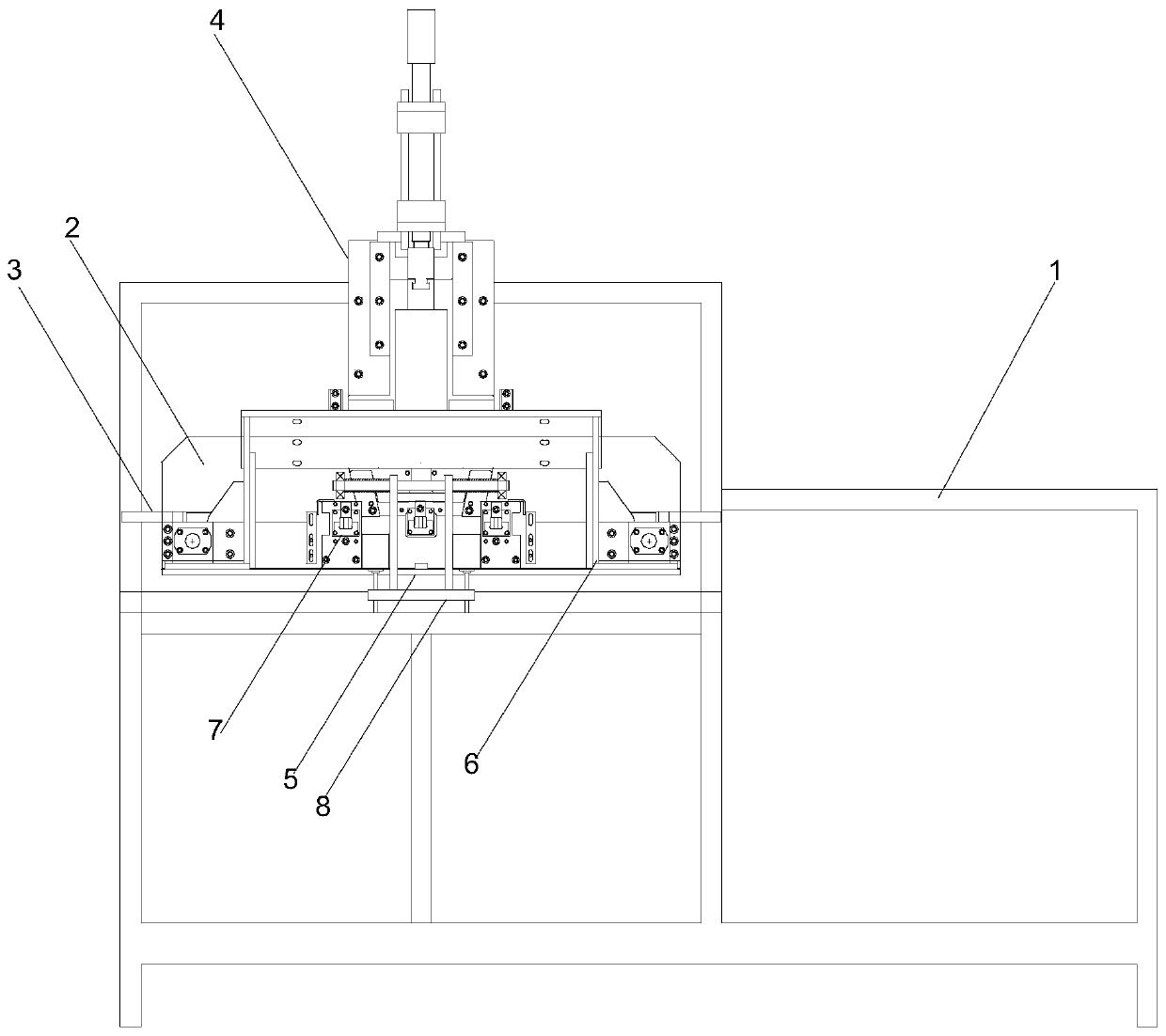

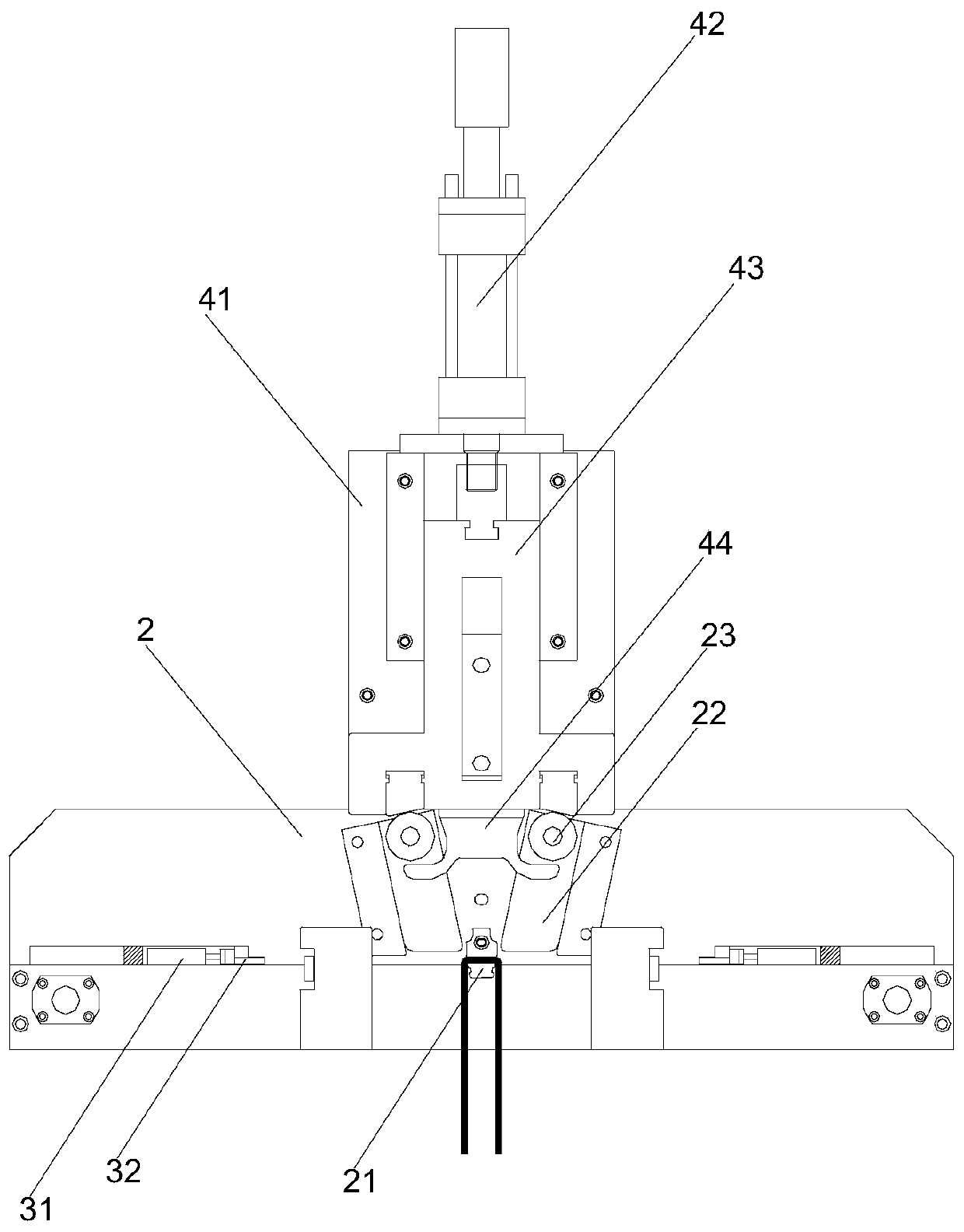

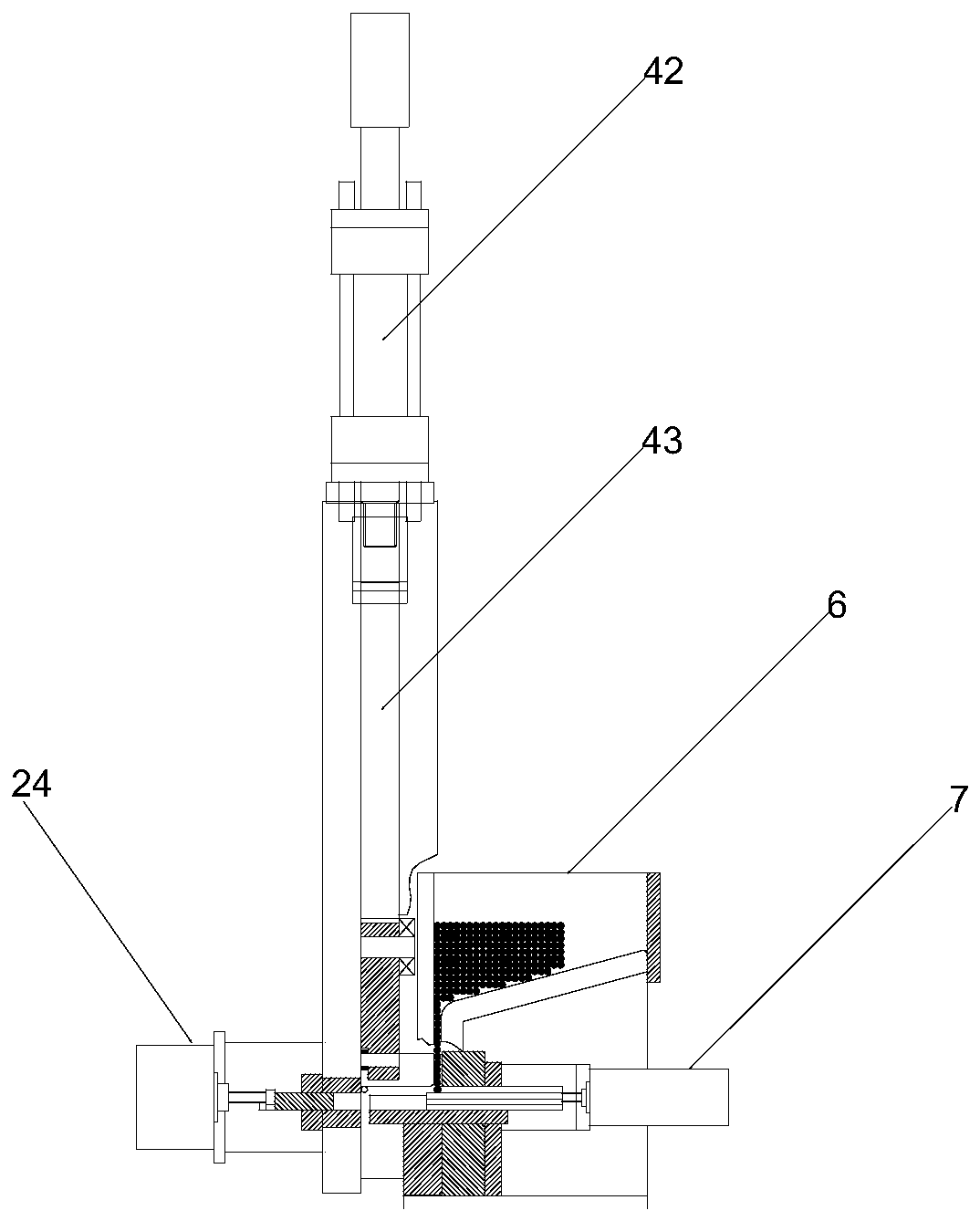

[0021] Such as Figure 1-Figure 3 As shown, the U-shaped wire forming machine of the present invention includes a frame 1, a processing plate 2 vertically fixed on the frame beam on the frame 1, and a knuckle is provided in the middle of the front of the processing plate 2 The mold core 21, the two sides of the corner mold core 21 are provided with a structurally symmetrical support device 3 on the surface of the processing plate 2, and the top of the processing plate 2 is provided with a wire bending device 4 for cooperating with the wire rolling on the angle mold core, The bending device 4 includes a bending vertical plate 41 fixed on the top of the processing plate 2. The bending vertical plate 41 is equipped with a bending oil cylinder 42 whose action direction is perpendicular to the corner die core 21. The movable end of the bending oil cylinder 42 is connected to There is a bending slider 43, and the lower part of the bending slider 43 is located on the front of the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com