Ink supply device, pad printing machine comprising same and method for controlling ink supply device

An ink supply device and pad printing machine technology, applied in printing machines, rotary printing machines, printing, etc., can solve problems such as high labor costs, rising costs, and difficulty in controlling production progress, so as to reduce labor intensity and ensure coating quality , the effect of reducing the risk of work-related injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

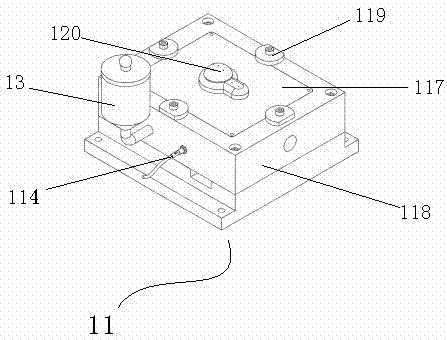

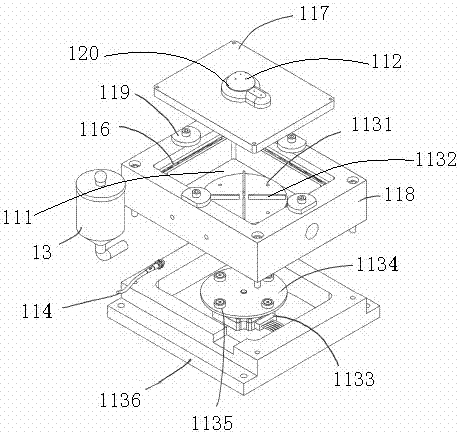

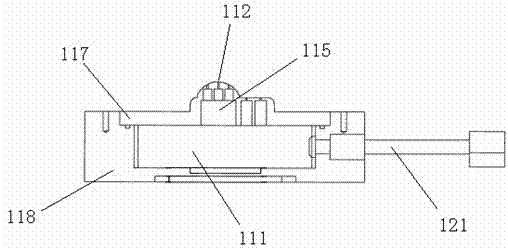

[0038] As shown in the figure, the ink supply device 1 of this embodiment includes an ink supply cartridge 11 with a cavity 111 inside, and the top surface of the ink supply cartridge 11 is provided with an ink port 112 communicating with the cavity 111. The ink supply device 1 also includes An extruding device 12 for extruding the ink in the cavity 111 to the ink port 112 is provided.

[0039] A stirring device is provided in the cavity 111, and the stirring device is made of a rotating disk 1131 made of a steel plate and an agitating plate 1132 on the rotating disk 1131; A transmission disc 1134 driven by a driving motor 1133 is provided, and a magnet 1135 is arranged on the transmission disc 1134 . The driving motor 1133 drives the transmission disc 1134 to rotate, and the magnetic force of the magnet 1135 on the transmission disc 1134 interacts with the turntable 1131 of the stirring device, thereby driving the turntable 1131 and the stirring plate 1132 to rotate, stirring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com