Butt welding all-in-one machine with automatic straightening and frame bending forming function

An all-in-one machine and automatic technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problem of retention length, bending accuracy welding point position not meeting the requirements, uneven metal wire deformation, low production efficiency, etc. problems, achieve significant economic benefits, improve production efficiency and molding effects, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

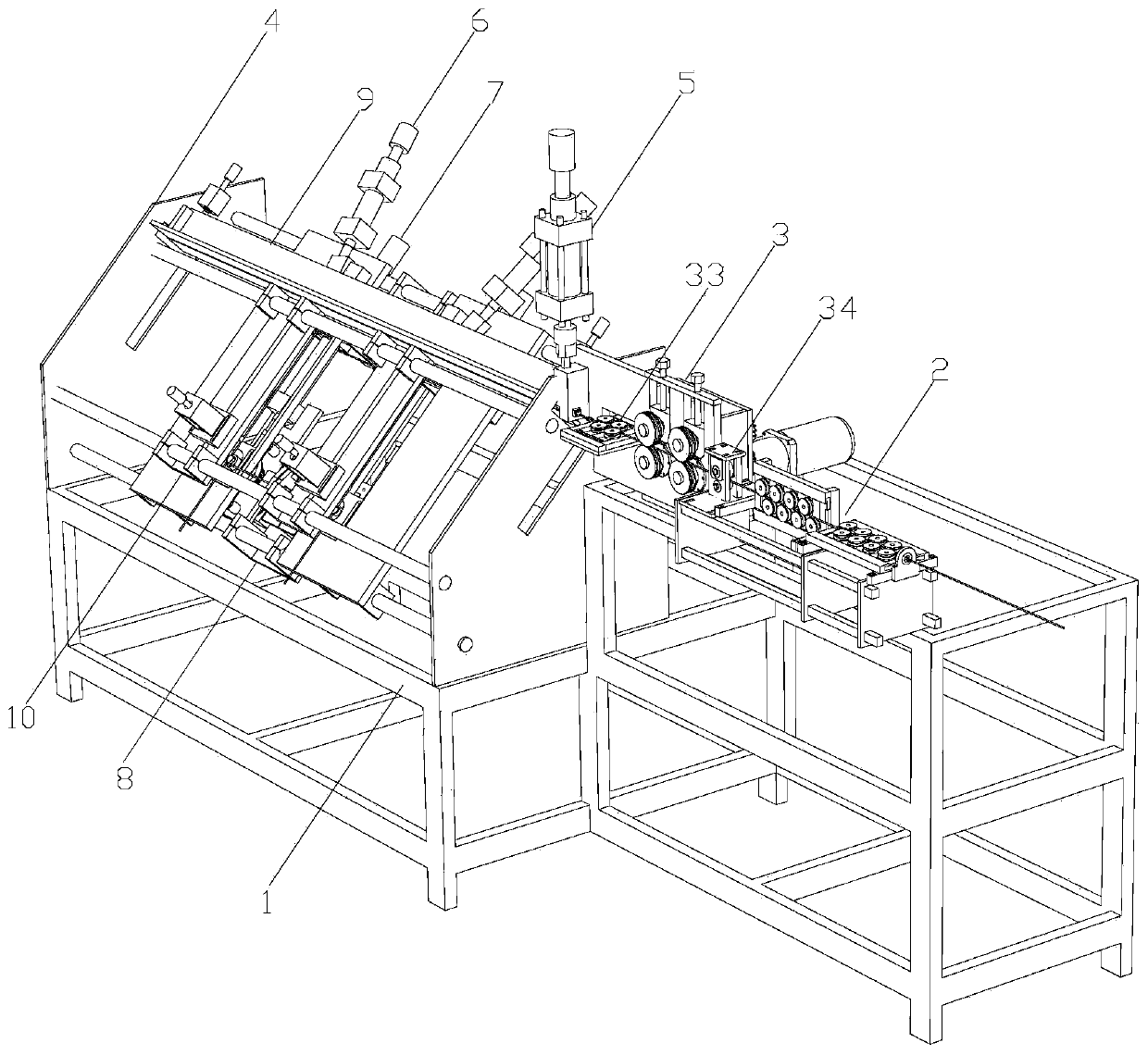

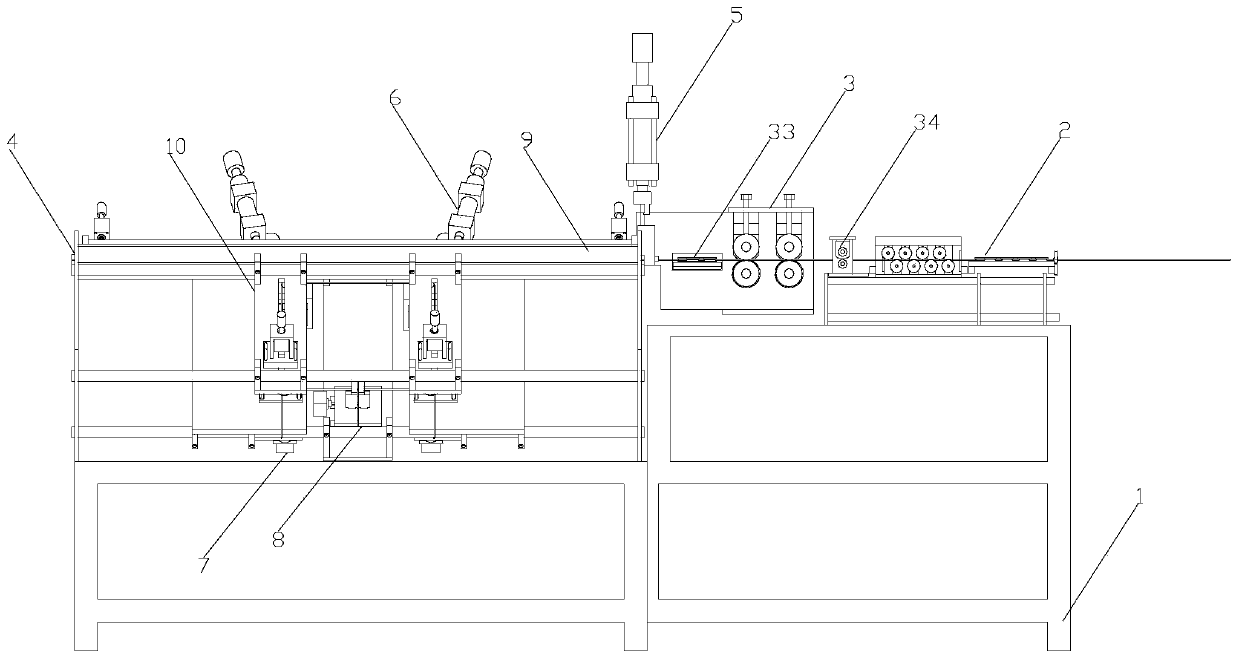

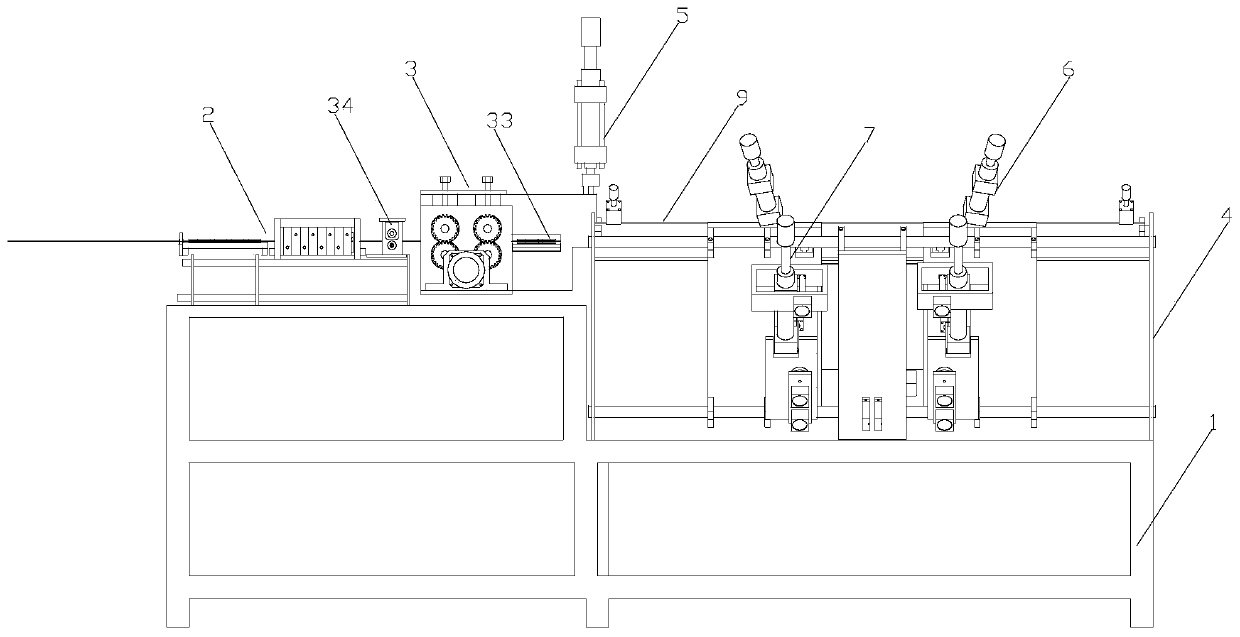

[0026] Such as Figure 1-Figure 4 As shown, the automatic straightening and bending frame butt welding integrated machine of the present invention includes a frame 1, and one end of the working surface of the frame 1 is provided with a wire adjustment assembly 2 for straightening and flattening the wire. The wire outlet side of the assembly 2 is located on the frame 1, and a wire assembly 3 for conveying wires is installed. Between the table 4 and the wire assembly 3, a cutter assembly 5 is provided to cut off the wire rod. The assembly operation table 4 is provided with two left and right bending panels 40 with symmetrical structures, and the upper ends of the two bending panels 40 are respectively There is an upper bending wire assembly 6 for rolling the wire rod inwardly at 90 degrees to the wire assembly 3, and the lower ends of the two bending wire panels 40 are respectively provided with an upper bending wire assembly 6 for rolling the wire rod inward at 90 degrees after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com