High foaming plastic packaging box

A high-foaming, box-packing technology, used in packaging, transportation and packaging, rigid containers, etc., can solve the problems of high cost, poor shockproof effect, and low foaming board magnification, and achieve low cost, reduced footprint, and reduced The effect of occupational injury risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

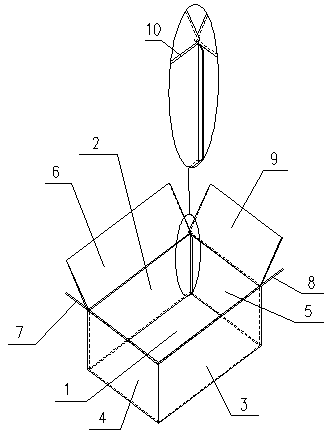

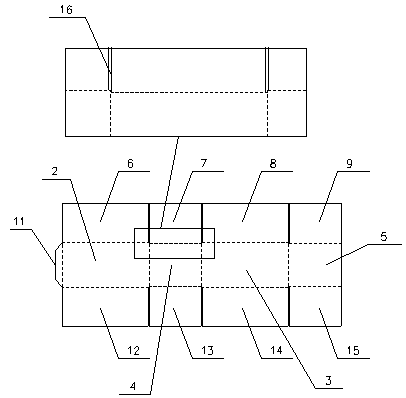

[0021] see Figure 1-2 , a high-foaming plastic packaging box, which is made by folding and fixing high-foaming plastic sheets. The high-foaming plastic sheets include a plastic high-foaming layer in the middle layer and an outer smooth, high-toughness, high-density foaming layer or non-foaming plastic. layer, the foaming ratio of the plastic high-foaming layer in the middle layer is 1-40; the high-foaming plastic sheet is made by compounding, extruding, gluing or thermoforming; the high-foaming plastic packaging box includes a box body, The box body adopts an integral structure, and the box body is a symmetrical structure up and down; the box body includes a bottom plate 1, a left side plate 2, a right side plate 3, a front panel 4, a rear panel 5 and an upper top plate; the bottom plate 1 includes The first lower bottom plate 12, the second lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com