CNC automated processing system and method

A processing system and automatic door technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as work-related injuries, waste of manpower and working hours, unstable process, etc., to save working hours, avoid frequent operations, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

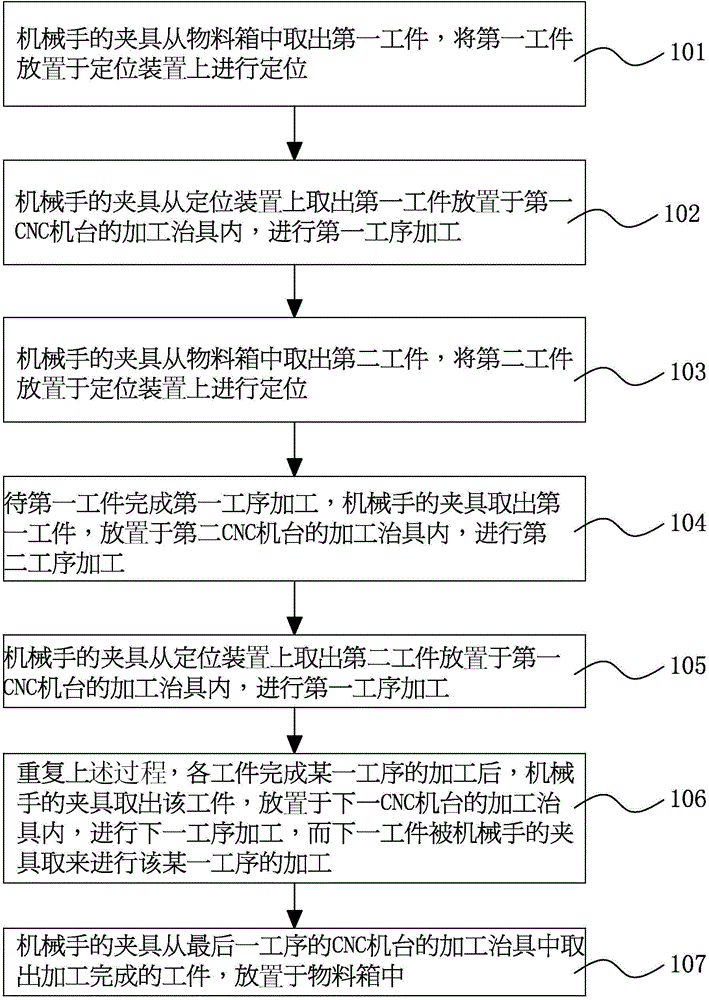

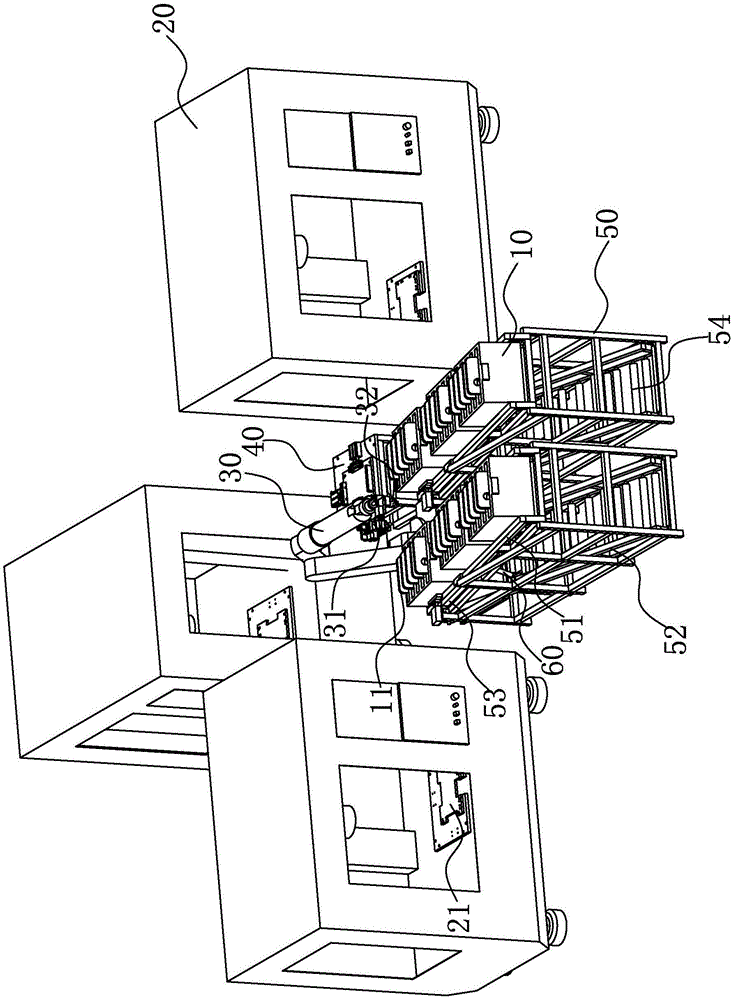

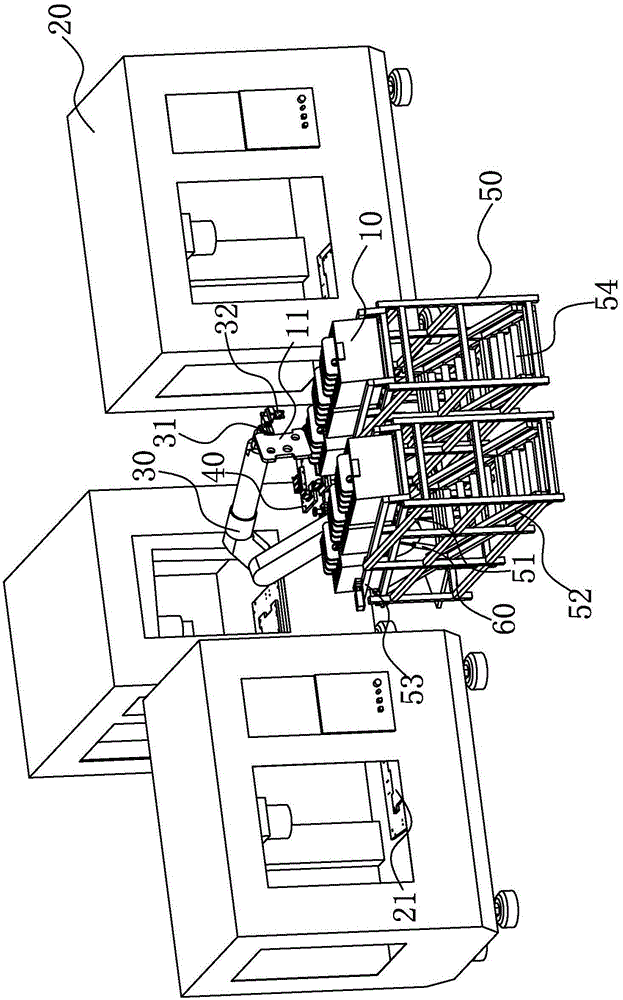

[0037] Please refer to Figure 1-8 , which are respectively shown as structural schematic diagrams of the first to eighth working states of the CNC automatic machining system of the present invention.

[0038] In order to achieve the above object, the CNC automatic processing system provided by the present invention includes:

[0039] A material box 10, in which several workpieces 11 to be processed are placed side by side;

[0040] A plurality of CNC machines 20 surround a processing area with the material box 10, each of the CNC machines 20 processes the workpiece 11 in different procedures, and each of the CNC machines 20 has a processing fixture twenty one;

[0041] Manipulator 30 (six axes here) is located in the processing area, the end of the manipulator 30 has a clamp for clamping the workpiece 11, and the manipulator 30 also has a controller (internal structure, not shown in the figure) ), the controller is respectively connected with each of the CNC machines 20, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com