Hybrid stepper motor rotor assembly machine

A stepper motor and hybrid technology, applied in the manufacture of stator/rotor bodies, etc., can solve the problems of unguaranteed assembly efficiency and quality, high requirements for operator proficiency, and reduced reliability of wrong teeth. The effect of assembly quality and stability, reducing labor intensity and improving the success rate of finale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

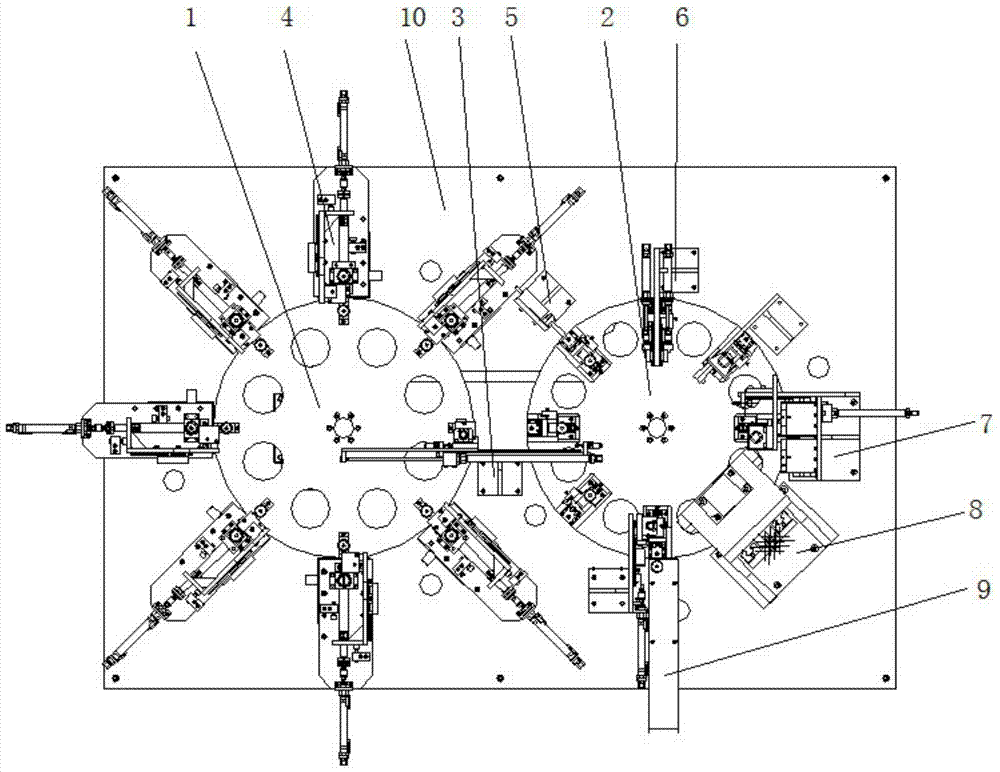

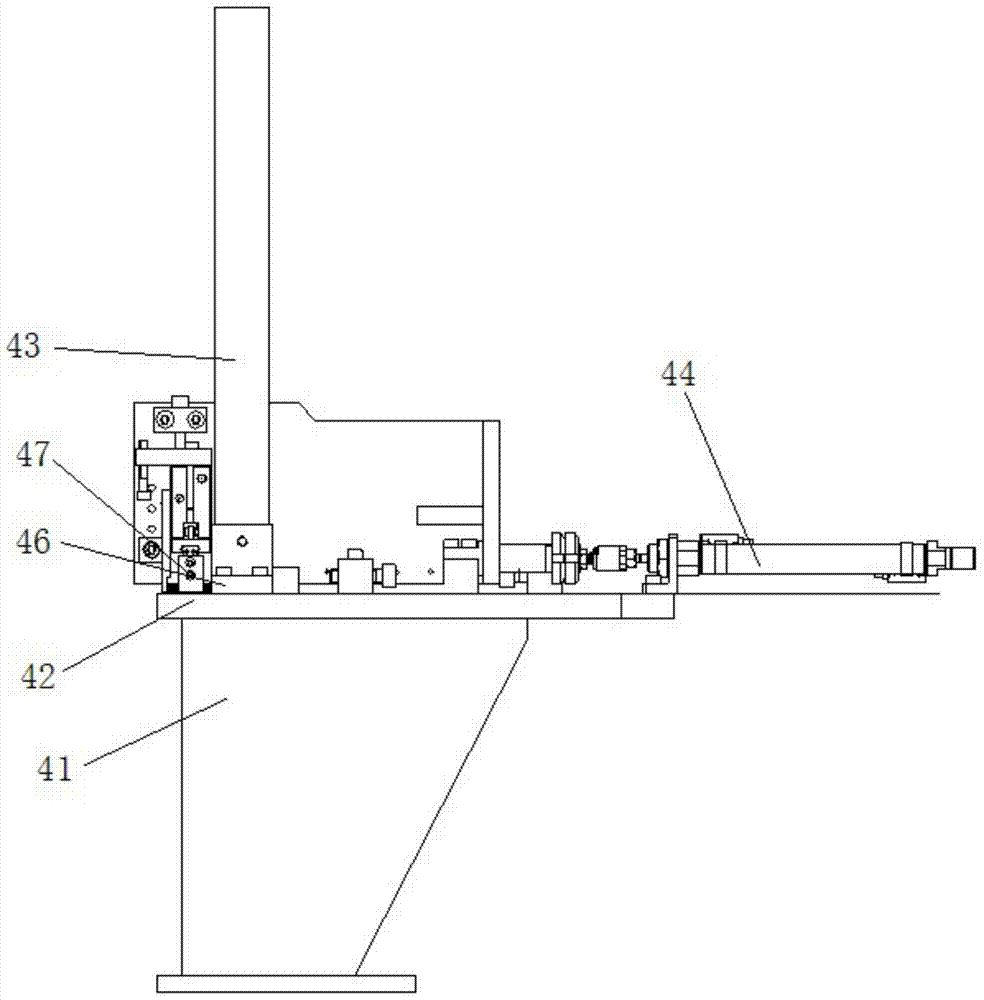

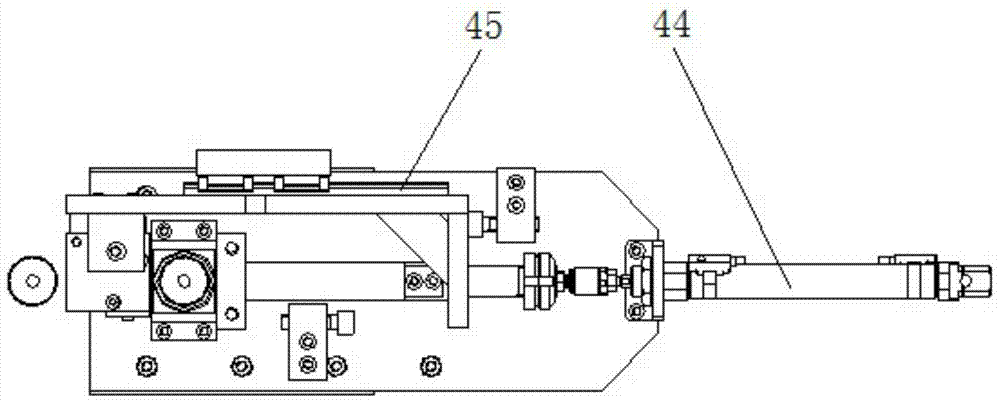

[0028] Figure 1 to Figure 10 As shown, a hybrid stepper motor rotor assembly machine includes a workbench 1, on which a rotor initial assembly disk 1 and a rotor press assembly disk 2 that can rotate are distributed, and the rotor initial assembly disk 1 and The rotor press mounting plate 2 is connected by the transmission of the rotor primary assembly exchange station 3, and a number of workpiece lamination stations 4 are arranged along the outer circumference of the rotor primary assembly plate 1, wherein the workpiece lamination stations 4 have seven groups; Clockwise along the outer circumference of the rotor press-fitting disc 2, there are sequentially provided with a clamp opening and closing device 5, a tooth-staggered station 6, a rotating shaft initial installation station 7, a rotating shaft pressing station 8, and a blanking station 9. The action and status of the entire assembly machine are controlled and monitored by the cooperation of PLC and touch screen.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com