Welded steel pipe welding groove flatly-cutting device capable of being stably fixed

A technology for welding steel pipes and welding joints, which is applied in the direction of sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve problems such as low safety factor, easy to cut fingers, and steel pipe fixing, so as to improve safety and reduce work-related injuries risk, effect of increased versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

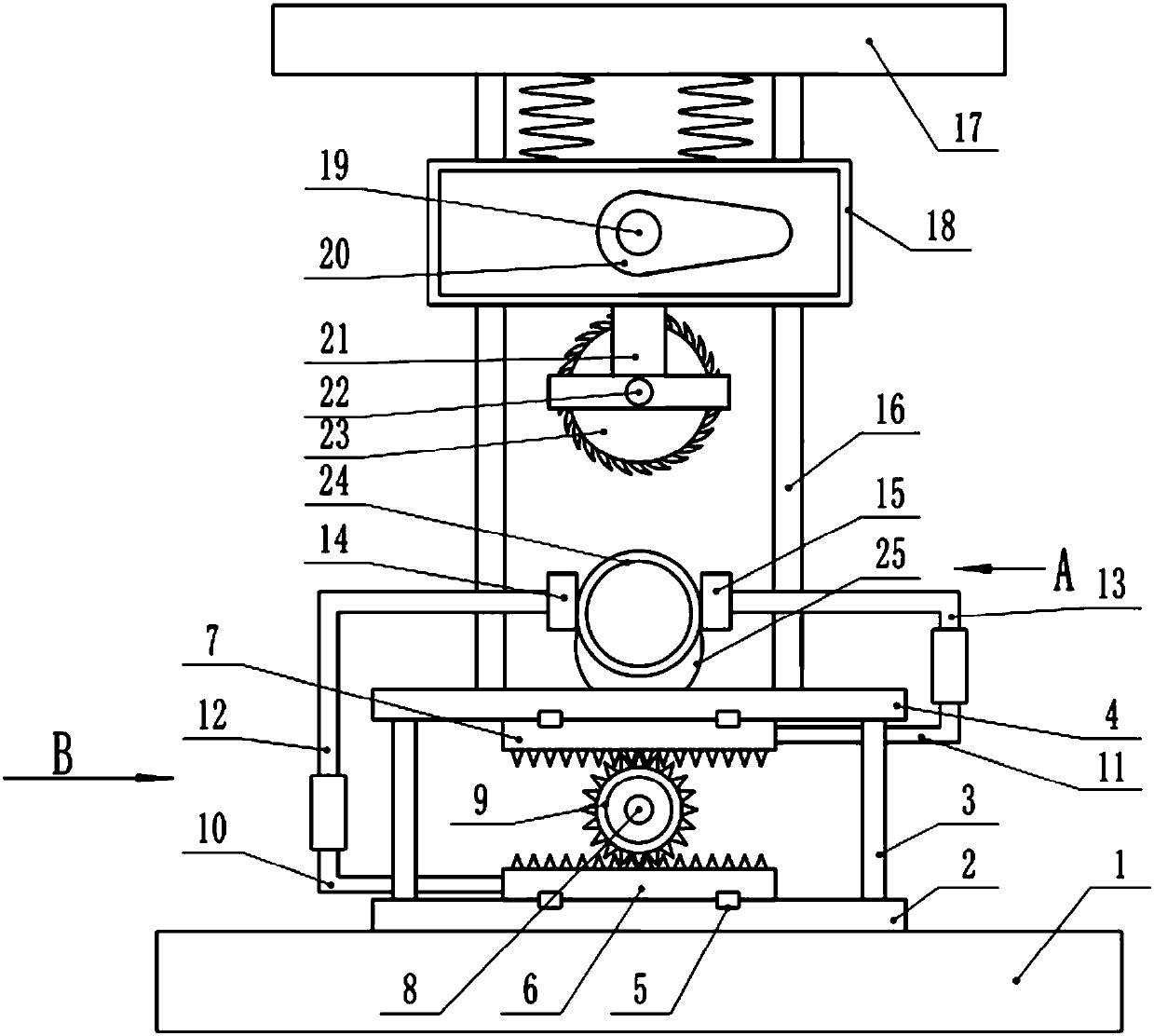

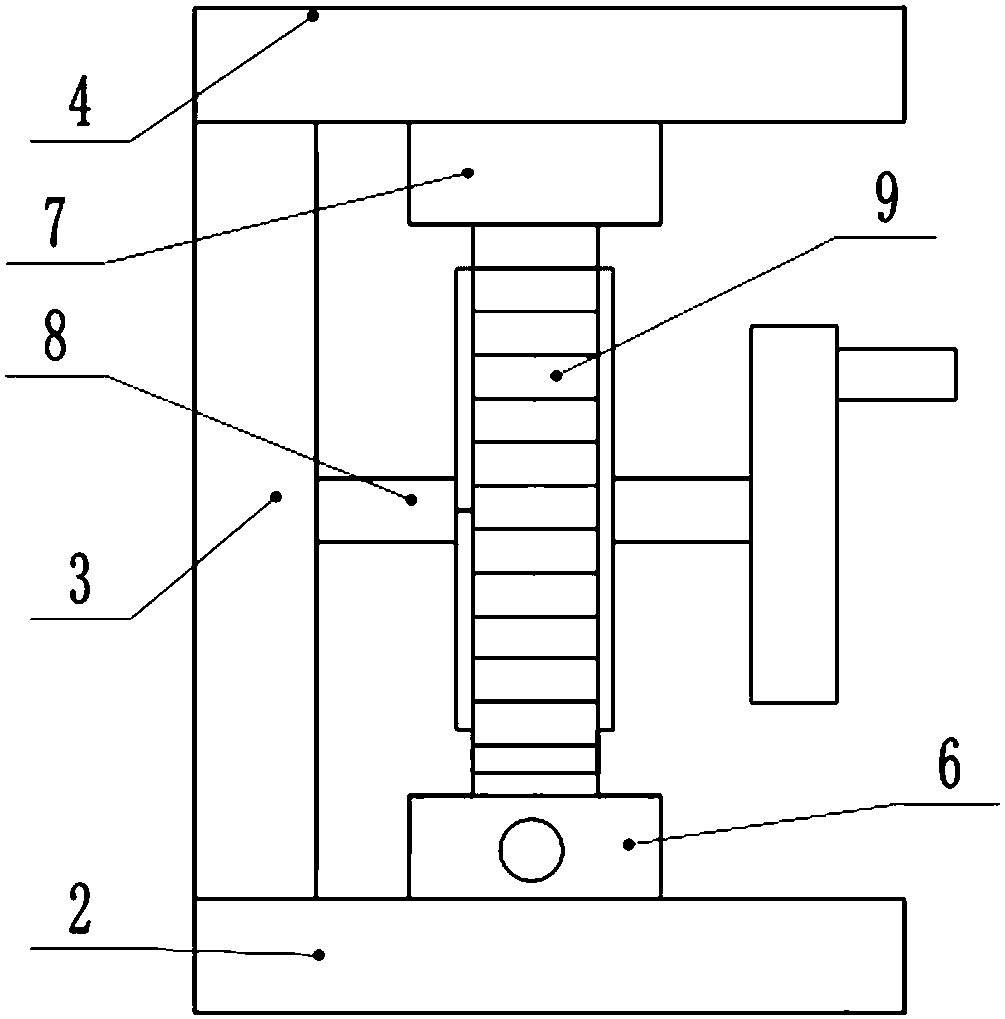

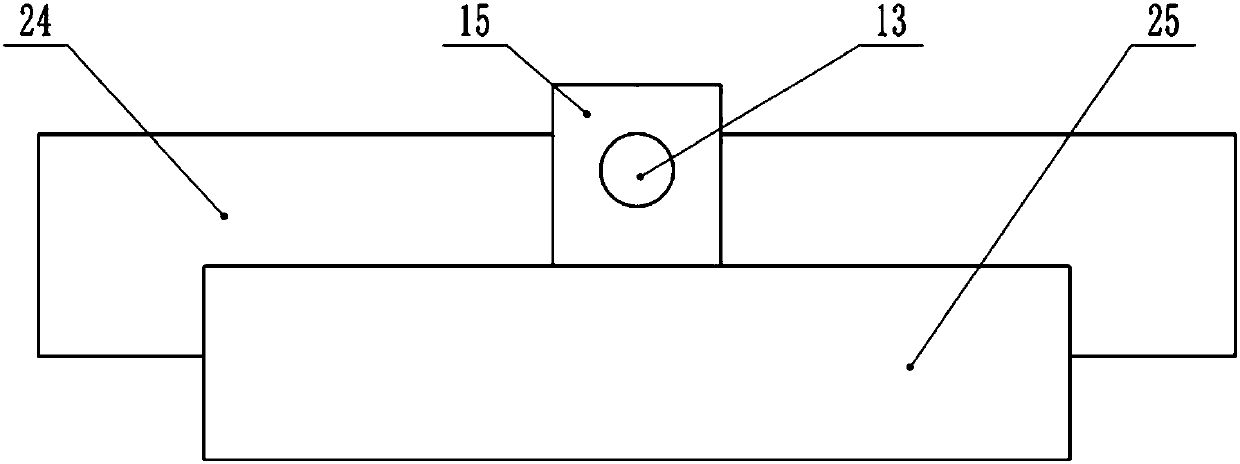

[0020] see Figure 1-3 , a fixed and stable welded steel pipe welding joint cutting device, including a base 1, a lower rack 6, an upper rack 7, a left clamping block 14, a right clamping block 15, a moving slide frame 18, a drive motor 19, a cam 20 and Cutting motor 22, described base 1 is provided with first slide rail 2, is fixedly connected by bolt between first slide rail 2 and base 1, and described first slide rail 2 is provided with first pillar 3, and first pillar 3 and the first slide rail 2 are connected by welding, and the upper end of the first pillar 3 is also welded to the second slide rail 4, and the first slide rail 2 and the second slide rail 4 are slidably installed with sliders 5. The slider 5 on the first slide rail 2 is fixedly welded with a lower rack 6, and the slider 5 on the second slide rail 4 is fixedly welded with an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com