Wavy wire molding machine

A forming machine and wavy wire technology, applied in the field of wire forming equipment, can solve problems affecting the ductility and toughness of wire rods, uneven deformation of steel wire rods, large internal stress, etc., achieve high production safety factor, improve production efficiency and forming effects, effects with a high level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

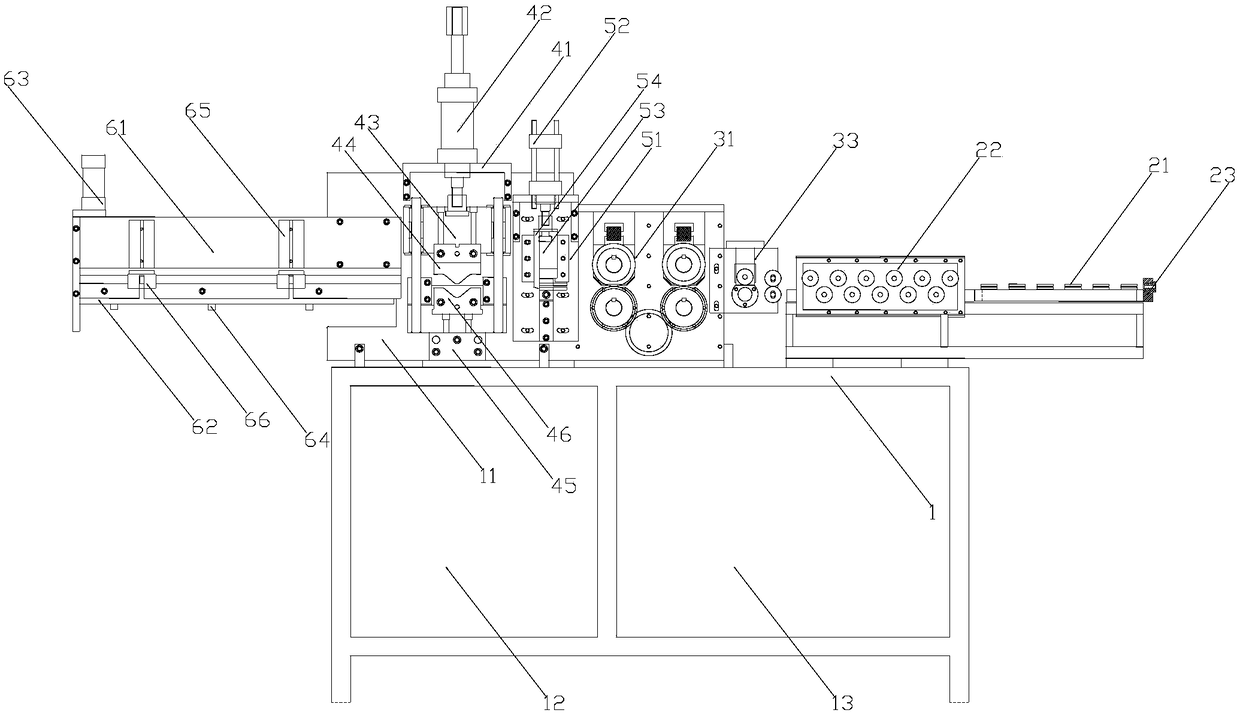

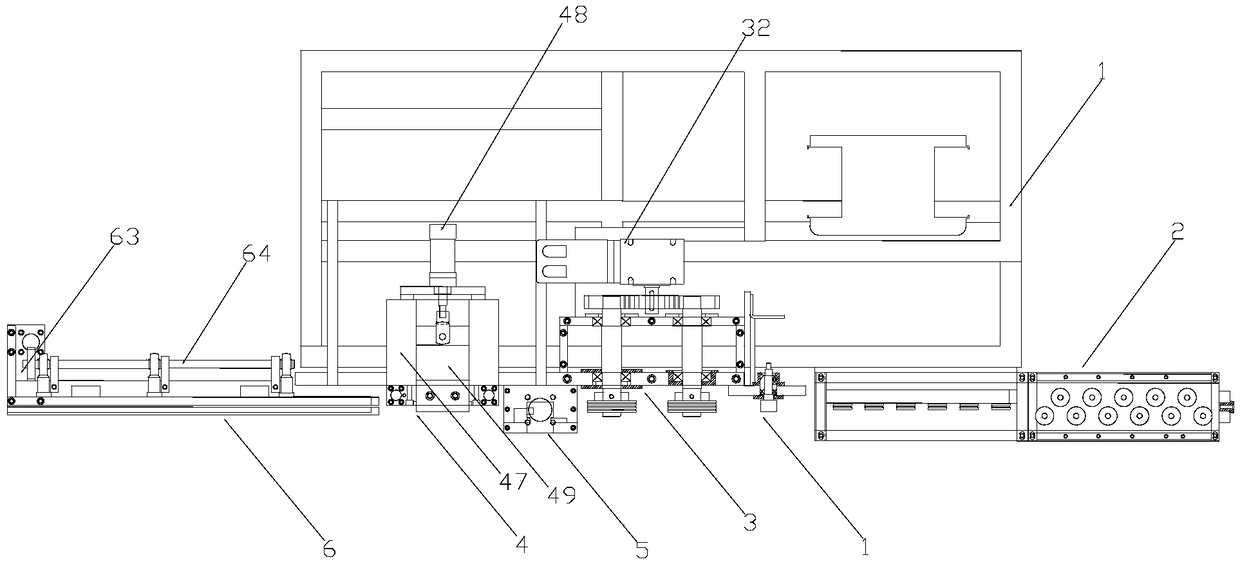

[0018] Such as Figure 1-Figure 2 As shown, the corrugated wire forming machine of the present invention includes a frame and an operating table 11, a driving part 12, and a control part 13 installed on the frame 1, and one side of the operating table is provided with a wire straightening and pressing machine. A flat thread adjustment mechanism 2, the thread adjustment mechanism 2 includes a horizontal pinch roller set 21 and a longitudinal pinch roller set 22, the crimping ports of the horizontal pinch roller set 21 and the longitudinal pinch roller set 22 are on the same horizontal plane, The wire inlet end of the horizontal pressure wheel group 21 is provided with a wire nozzle 23, and the wire outlet end of the wire adjustment mechanism 2 is located on the console 11, and a wire mechanism 3 for conveying wires is installed on the wire mechanism 3. The wire mechanism 3 is installed on the On the operating table 11 between the rolling mechanism 4 and the wire adjustment mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com